Rachet looseness prevention fine adjusting clamp

A technology for fine-tuning fixtures and pawls, which is used in clamping, clamping devices, manufacturing tools, etc., can solve the problems of low positioning accuracy, easy loosening, and difficult fine-tuning, and achieve improved positioning accuracy, simple structure, and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

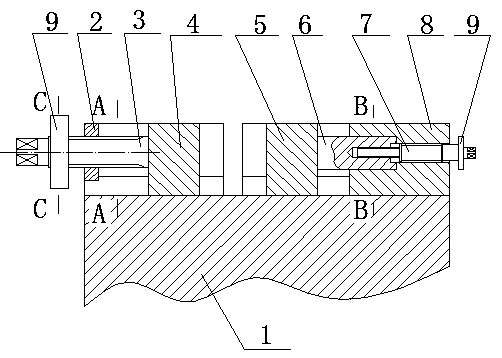

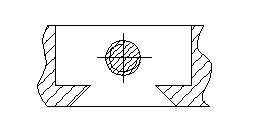

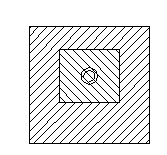

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the pawl anti-loosening fine-tuning fixture includes fixture seat 1, left fixing block 2, large screw rod 3, left clamping block 4, right clamping block 5, guide rod 6, fine-tuning screw rod 7, right fixing block 8, ratchet Claw anti-loosening device 9, gear 10, outer ring 11, spring 12, pawl 13, screw 14, said fixture seat 1 is provided with a dovetail groove, and a left fixing block 2 and a right fixing block are arranged at both ends of the dovetail groove Block 8, the left fixed block 2 and the right fixed block 8 are all provided with threaded holes, the left clamping block 4 and the right clamping block 5 are all assembled in the dovetail groove on the fixture seat 1, the described One end of the large screw 3 is fixedly connected with the left clamping block 4, and the other end is engaged with the thread of the left fixed block 2. One end of the guide rod 6 is fixedly connected with the right clamp...

Embodiment 2

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the pawl anti-loosening fine-tuning fixture includes fixture seat 1, left fixing block 2, large screw rod 3, left clamping block 4, right clamping block 5, guide rod 6, fine-tuning screw rod 7, right fixing block 8, ratchet Claw anti-loosening device 9, gear 10, outer ring 11, spring 12, pawl 13, screw 14, said fixture seat 1 is provided with a dovetail groove, and a left fixing block 2 and a right fixing block are arranged at both ends of the dovetail groove Block 8, the left fixed block 2 and the right fixed block 8 are all provided with threaded holes, the left clamping block 4 and the right clamping block 5 are all assembled in the dovetail groove on the fixture seat 1, the described One end of the large screw 3 is fixedly connected with the left clamping block 4, and the other end is engaged with the thread of the left fixed block 2. One end of the guide rod 6 is fixedly connected with the right clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com