Clamping jaw mechanism for flexible flat cable automatic striping device

A flexible cable, automatic technology, applied in the field of gripper mechanism, can solve the problems of inaccurate peeling position of flexible cable, offset of incision, affecting processing and use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

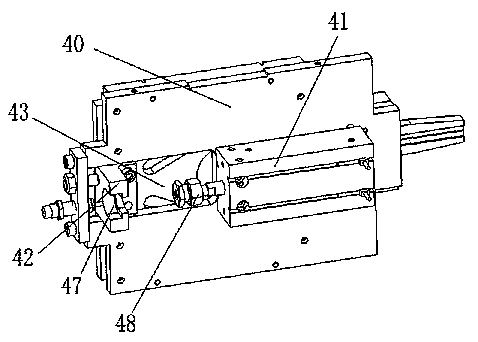

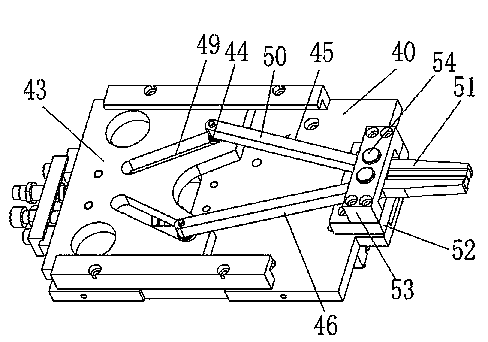

[0012] Such as Figure 1-2 As shown, a clamping jaw mechanism of a flexible cable automatic slitting device includes a bottom plate 40, a cylinder 41, a moving block 42, a sliding plate 43, a cam 44, a left clamping arm 45 and a right clamping arm 46, on the bottom plate 40 The back is provided with a slideway, and the moving block 42 is arranged in the slideway and is fixedly connected with the sliding plate 43 positioned at the top of the bottom plate 40. A slot 47 is arranged in the moving block 42, and the cylinder rod 48 of the cylinder 41 at the back of the bottom plate 40 is locked. Connected in the draw-in groove 47, two inclined grooves 49 are symmetrically arranged on the sliding plate 43, and the ends of the left clamping arm 45 and the right clamping arm 46 slide along the inclined grooves 49 through the cam 44 respectively, and the left clamping Arm 45 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com