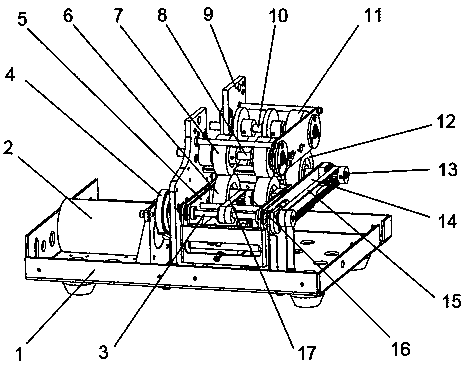

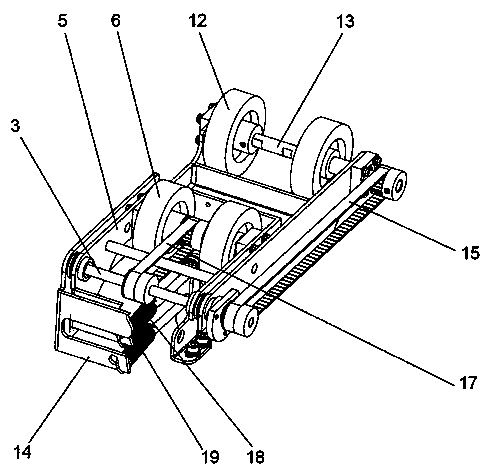

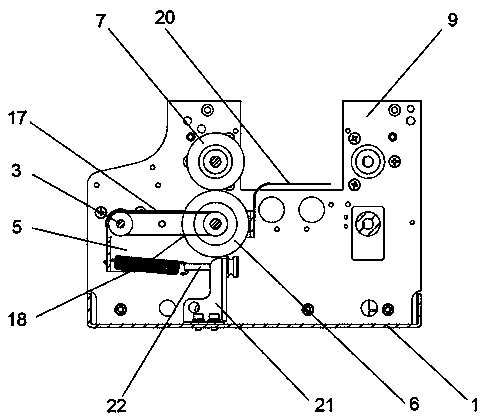

Postage machine feeding device

A postage meter and delivery technology, applied in the printing device, printing, etc., to achieve the effects of facilitating maintenance and installation, improving printing quality, and facilitating adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The delivery device of the postage machine, including the frame and the bracket fixedly connected with it, the stepping drive motor and the drive shaft passing through the frame are connected through the timing belt; there are two groups of rollers in the front and rear, and two groups of rollers in the front and rear They are respectively installed on the front and rear sides of the print head. Each set of rollers is divided into an upper roller set and a corresponding lower roller set. The upper roller set and the lower roller set have two rollers respectively; a rotating shaft Installed on the bracket through bearings, the upper roller set is installed on this rotating shaft; divided into front and rear subframes, the subframe is U-shaped, and the front subframe is connected with the front roller set, which is connected with the rear roller set The rear subframe is the rear subframe, and the front subframe is installed on the inner side of the rear subframe; the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com