Product multi-end clamping and conveying device

A clamping and conveying, multi-terminal technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of small application range, poor clamping stability, and easy to clamp damaged products, so as to improve safety and reliability, avoid The effect of clamping damage and high clamping synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

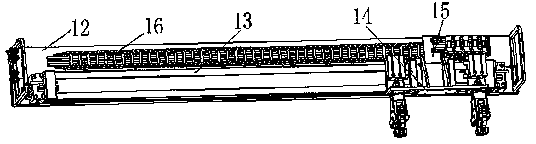

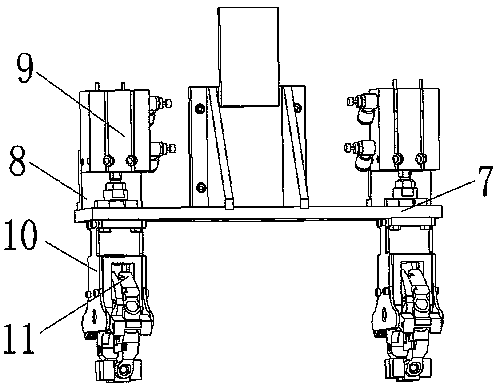

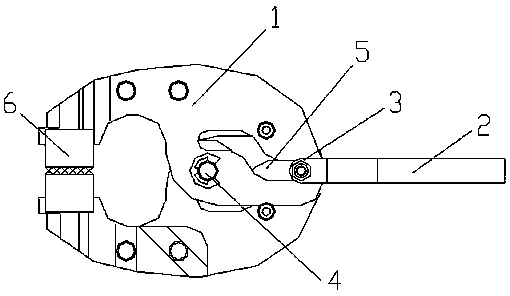

[0017] Such as Figure 1-3 As shown, a product multi-terminal clamping and conveying device includes a strip-shaped fixed plate 12, a slide cylinder 13, a multi-terminal clamping mechanism 14 and a cable protection chain 16, and the multi-terminal clamping mechanism 14 includes a moving plate 15, a supporting plate 7. Two rear plates 8, two cylinders 9, two single clamping mechanisms 11 and four side plates 10, a sliding table cylinder 13 is arranged on the front surface of the elongated fixed plate 12, and the middle part above the support plate 7 There is a moving plate 15, the moving plate 15 is connected with the sliding portion of the slide cylinder 13, a rear plate 8 is respectively arranged on the top position of the supporting plate 7 on both sides of the moving plate 15, and a rear plate 8 is arranged on the front surface of the rear plate 8. There is a cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com