Helical feeding mechanism

A technology of screw feeding and screw conveyor, applied in the field of screw feeding mechanism, can solve the problems of uncontrollable feeding speed, excessive feeding, loss and waste of raw materials, etc., and achieve the effect of expanding the combustion contact area, improving combustion efficiency and saving fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

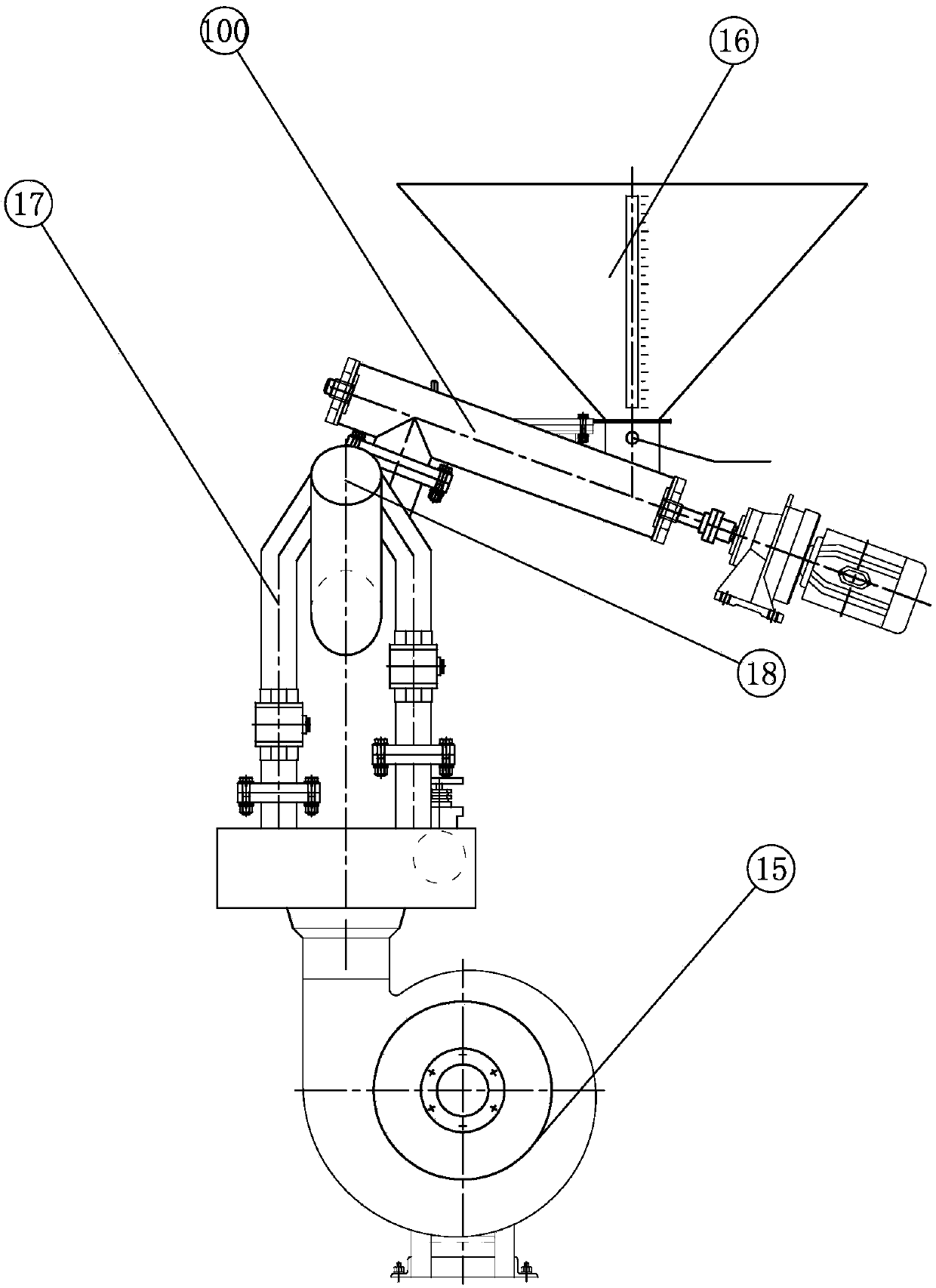

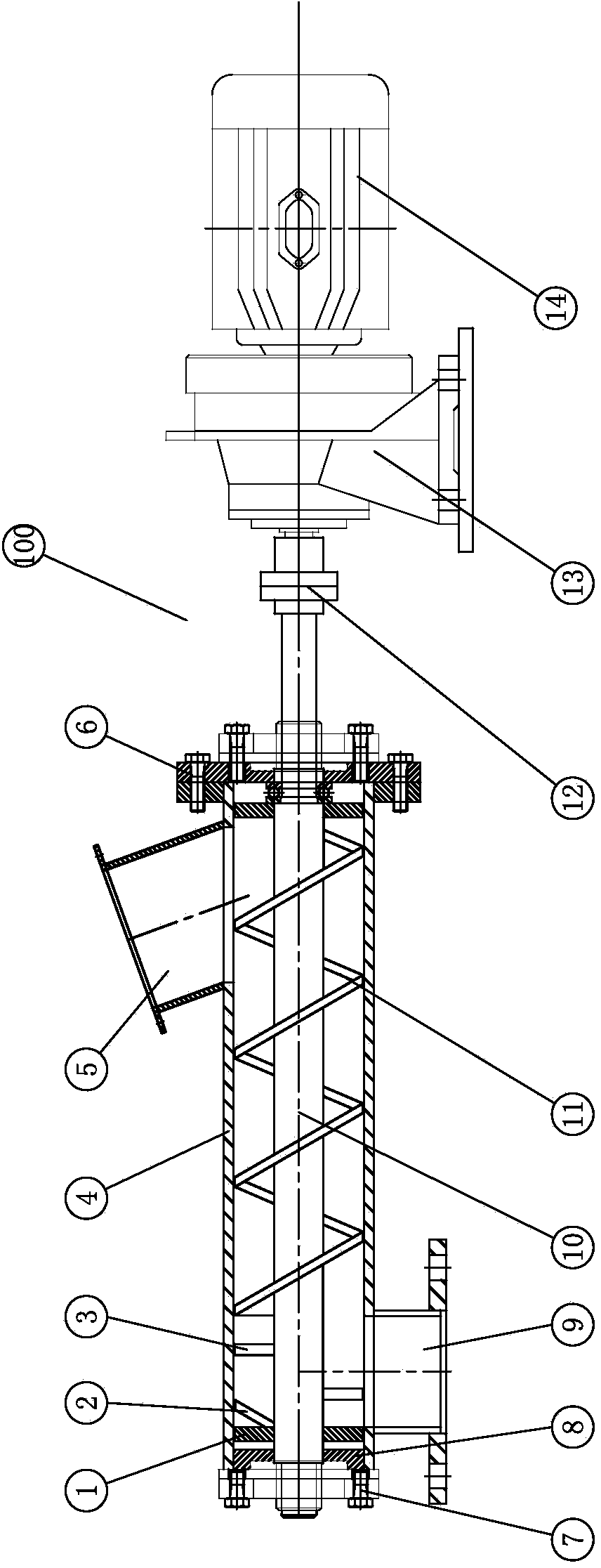

[0015] Embodiment: First, put the material into the feeding device 16, the material enters the barrel 4 through the feed port 5, starts the motor 14, and after being decelerated by the cycloidal pin wheel reducer 13, the power of the motor 14 passes through the shaft coupling 12 It is transmitted to the feeding shaft 10. With the rotation of the feeding shaft 10, the rotation of the screw blade 11 is driven, and the material is sent to the upper end of the barrel 4. After the material is crushed by the crushing knife 3, it is blocked at the baffle plate 1, and then passed through The blanking port 9 is blown into the discharge port 18 through the air flow of the air supply pipe 17, and enters the next link for utilization. There are two air supply pipes 17, which can be opened and closed according to the material demand, and controlled by adjusting the gear position of the fan 15. The air volume can be controlled to achieve the purpose of controlling the air volume.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com