Wire feeding mechanism capable of prolonging wire feeding travel

A wire feeding and stroke technology, applied in the field of wire feeding mechanism that can extend the wire feeding stroke, can solve the problems such as the inability to send the wire to the tool holder, the short wire feeding stroke, the short wire feeding distance of the wire feeding mechanism, etc. Occupied space, smooth wire feeding, and effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

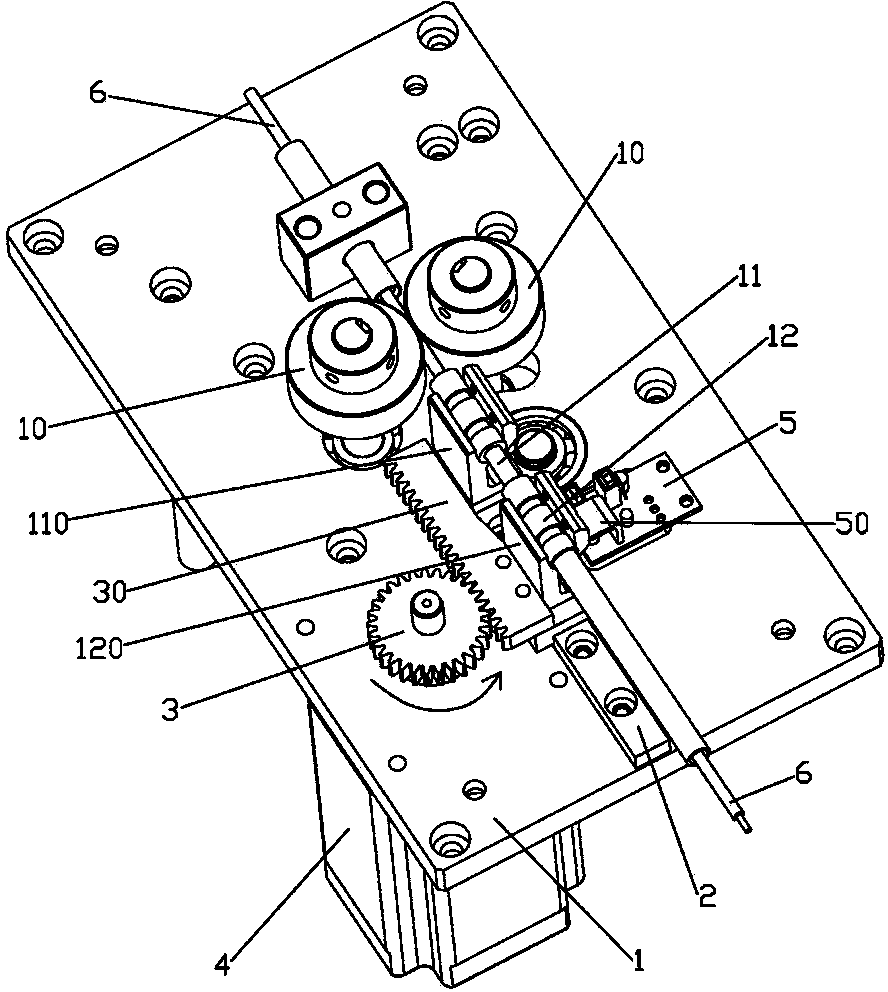

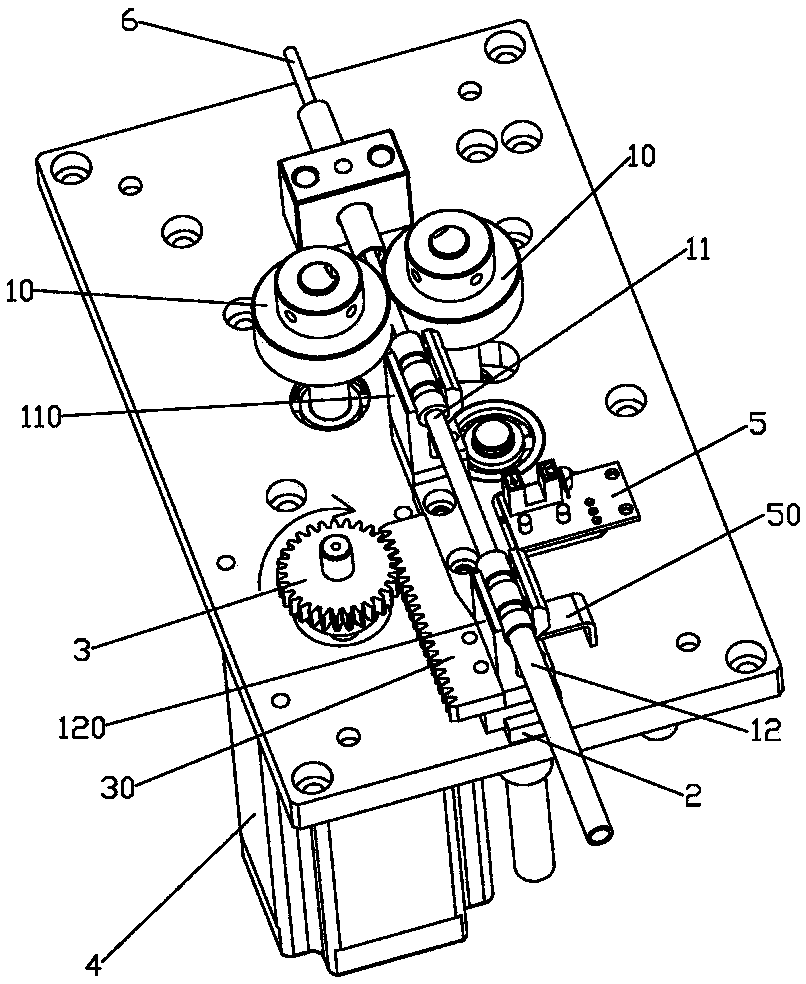

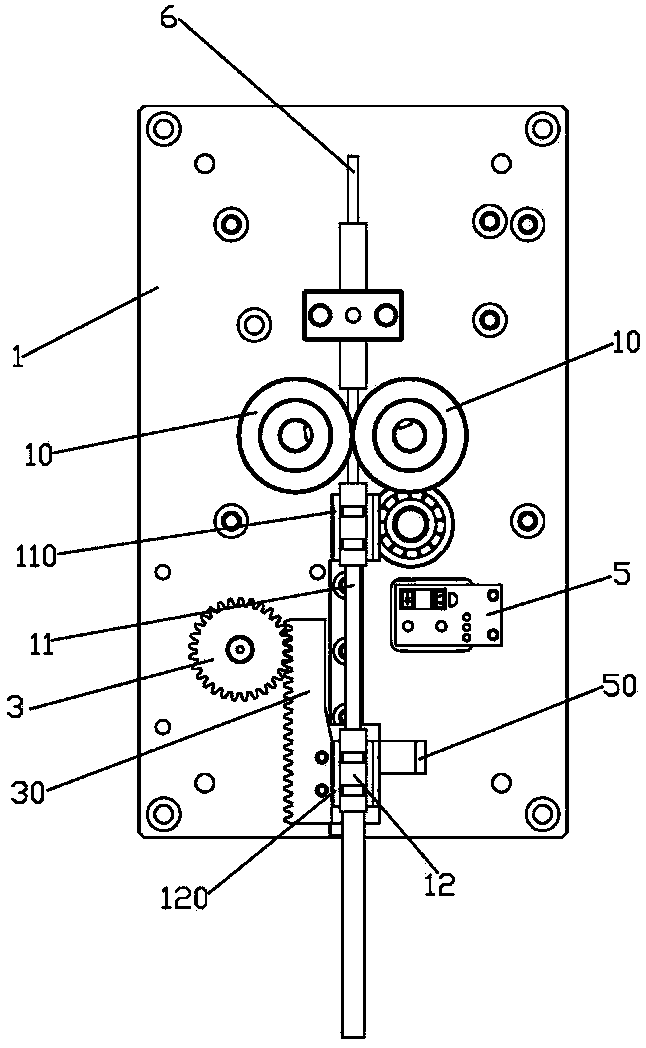

[0015] refer to figure 1 to Figure 3 ( figure 1 , figure 2 The direction of the middle arrow indicates the direction of rotation of the drive gear), a wire feeding mechanism capable of extending the wire feeding stroke, including an upper panel 1 with a wire feeding wheel 10 on the surface, and a wire feeding wheel 10 is provided at the outlet of the wire feeding wheel 10. The first conduit 11 of the wire, the first conduit 11 is fixedly installed on the upper panel 1 through the first nozzle bracket 110, and the first conduit 11 is also movably sleeved with a second conductor that can move relative to it Pipe 12, the second wire pipe 12 is slidably installed on the guide rail 2 through the second nozzle bracket 120, and the guide rail 2 is fixedly installed on the upper panel 1, and the side wall of the second nozzle bracket 120 is fixedly provided with teeth A bar 30, one side of the rack 30 is provided with a drive gear 3 for driving it to move back and forth along the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com