Method of producing substitute natural gas from synthesis gas

A technology that replaces natural gas and synthetic gas. It is applied in the direction of gas fuel, petroleum industry, fuel, etc. It can solve the problems of excess components, etc., and achieve the effects of high-grade product rate improvement, good technical effect, and short reaction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

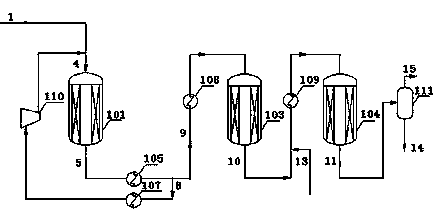

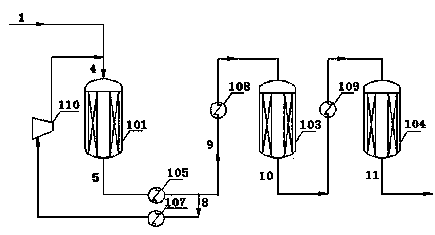

[0028] A certain 1.2 billion Nm 3 / year synthetic gas to replace natural gas plant (8000 operating hours per year), using figure 1 process technology, the composition of raw material synthesis gas 1 is: (H 2 -CO 2 ) / (CO+CO 2 )=3.05, the pressure is 3.5MPa, and the feed rate is 600,000 Nm 3 / h, the stream 4 mixed with the recycle gas 8 enters the high-temperature methanation reactor 101 at a temperature of 300°C to undergo a methanation reaction, and the methanation reactor is filled with a Ni-based catalyst (wherein Al 2 o 3 Carrier 60%, nickel 35%); reaction outlet stream 5 temperature 650°C, after being cooled by high-temperature methanation reactor outlet cooler 105, it is divided into 2 shares, the volume ratio of stream 5 and stream 8 is 1.4, and material 8 is circulated The gas cooler 107 is cooled and the circulation compressor 110 is compressed to 3.5 MPa, and then mixed with the synthesis gas as the circulation gas, and the circulation compressor adopts a centrif...

Embodiment 2

[0032] With [embodiment 1], only raw material synthesis gas 1 is formed into: (H 2 -CO 2 ) / (CO+CO 2 )=3.2, add CO 2 The gas volume is 12000Nm 3 / h, the volume ratio of stream 13 to stream 10 is 0.035.

[0033] The volume content of each component of natural gas produced by the device is: CH 4 95.6%, H 2 0.8%, CO 2 1.8%, N 2 1.8%, the high-temperature methanation reaction CO conversion rate is 71%, the energy consumption of the compressor is 4900KW, and the high-grade product rate is 97.5%.

[0034]

Embodiment 3

[0036] A certain 1.2 billion Nm 3 / year synthetic gas to replace natural gas plant (8000 operating hours per year), using figure 1 process technology, stream 13 is composed of H 2 : 17%, CO: 3%, CO 2 : 80% mixed gas, additional gas volume is 10000Nm 3 / h, the volume ratio of logistics 13 and logistics 10 is 0.03, and all the other conditions are the same as [embodiment 1].

[0037] The volume content of each component of natural gas produced by the device is: CH 4 95%, H 2 1.0%, CO 2 2.2%, N 2 1.8%, the high-temperature methanation reaction CO conversion rate is 70%, the energy consumption of the compressor is 4800KW, and the high-grade product rate is 97%.

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com