Constant pressure methane tank

A biogas digester and biogas technology, which is applied in the fields of gas production bioreactors, biochemical instruments, waste fuels, etc., can solve the problems of unstable pressure, unstable biogas pressure, and reduced pressure in the biogas digester. Fire, easy feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

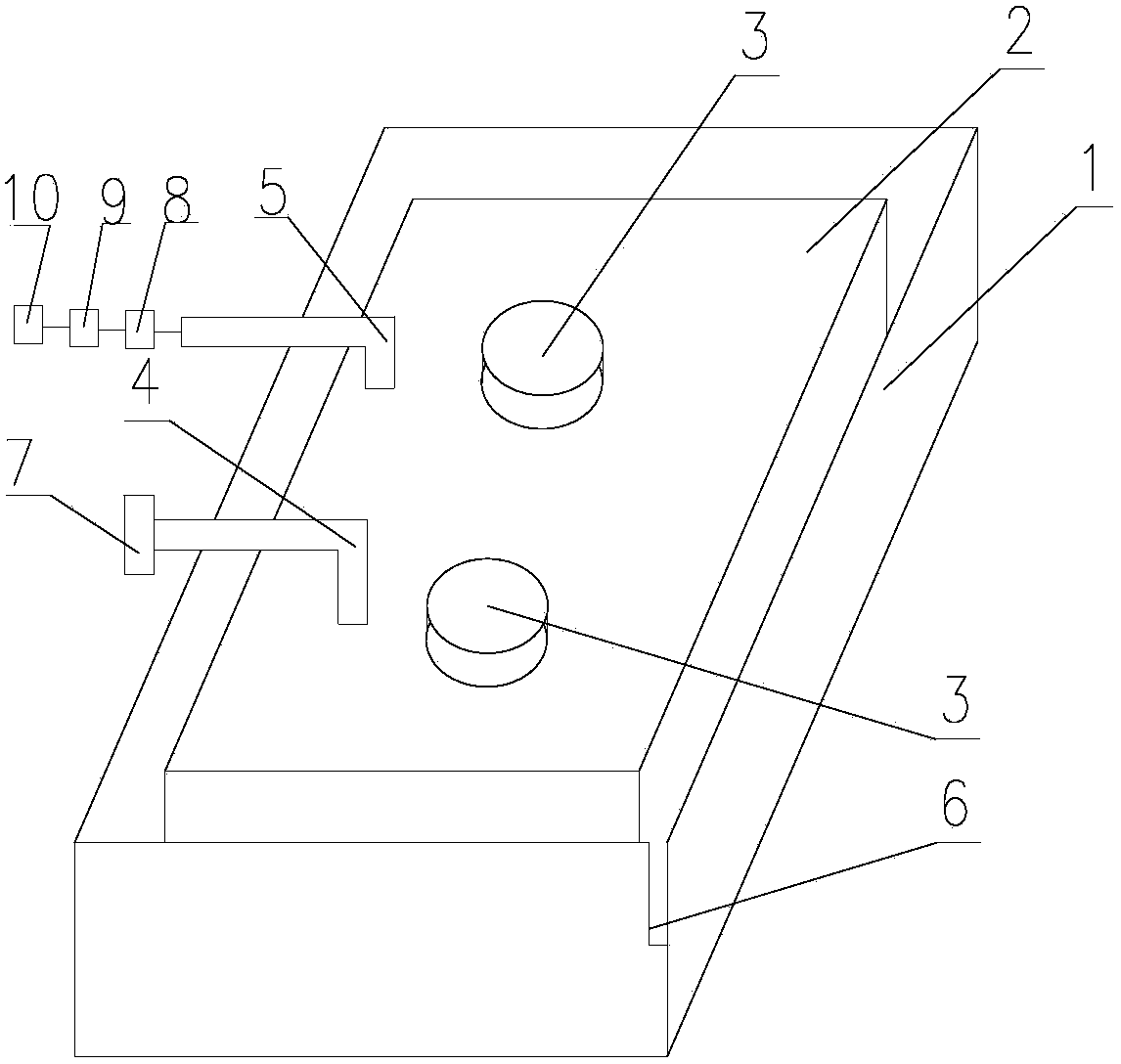

[0020] figure 1 A schematic structural view of the constant pressure biogas digester of the present invention is shown. As can be seen from the figure, a constant pressure biogas digester includes: a biogas bottom pond 1 with an upper opening and a bottomless biogas pond cover covered on the biogas bottom pond 1 2. The bottomless biogas tank cover 2 is slightly smaller than the biogas bottom tank 1. The bottomless biogas tank cover 2 can freely move up and down according to the amount of biogas in the biogas tank. The bottomless biogas tank cover 2 is set There are excrement outlet 3, catheter 4 and airway 5. The fermented material is placed in the space formed by the biogas bottom tank 1 and the bottomless biogas tank cover 2, and the biogas generated after the fermentation of the fermented material is directly stored in the bottomless biogas tank cover 2, and the pressure of the generated biogas can make the bottomless biogas tank cover 2 Jacking up, the lifting of the bott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com