Split full-length grouting anchorage facility

A split-type, full-length technology, used in construction, sheet pile walls, infrastructure engineering, etc., can solve problems such as uneven bonding stress, and achieve the effects of fast construction, improved bearing capacity, and low clearance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

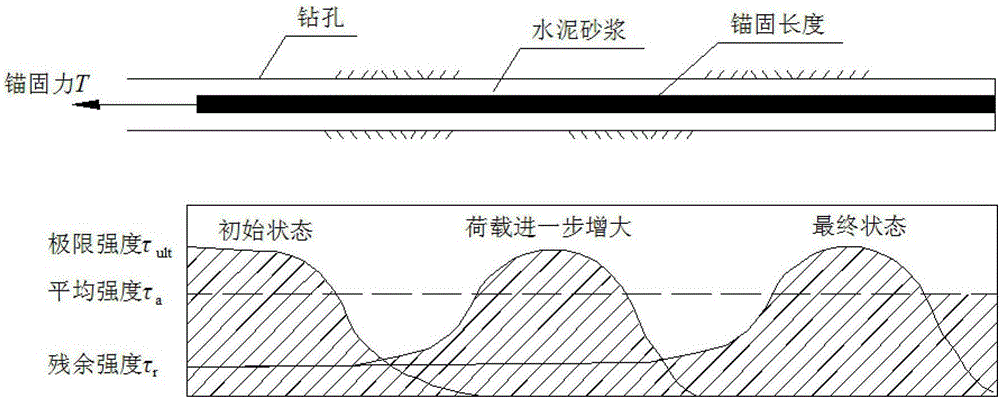

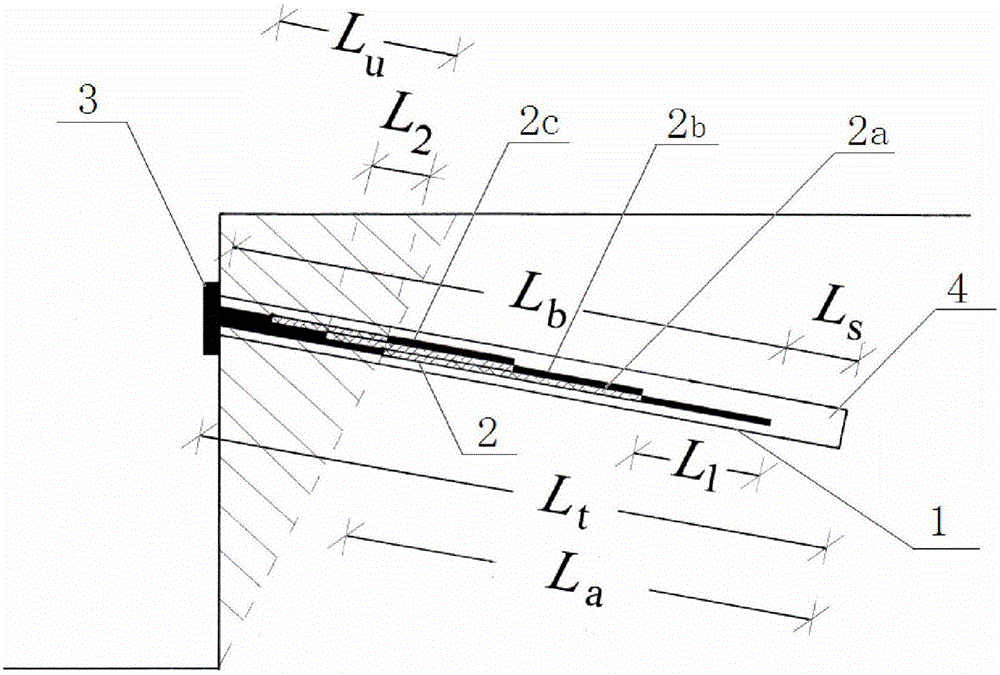

[0019] like image 3 , Figure 4 As shown, the present invention is a split-type full-length grouting anchoring facility anchored in a slope, consisting of an anchor rod 1, an anchor bar 2 located in the anchor rod 1, a reaction steel plate 3 at the head end of the anchor rod 1, and an anchor rod 1. The sediment section 4 poured with cement mortar is formed. The anchor rod 1 is anchored in the unstable body and the stable body of the slope. The anchor bars 2 are three anchor bars of unequal length arranged side by side: a long anchor bar (2a), a middle anchor bar (2b) and a short anchor bar (2c). Each anchor bar is divided into an unbonded section and a stressed section. The unbonded section is a section wrapped with high-strength polyester tape on the anchor bar, and the exposed part of the anchor bar is the stressed section (ie, the bonded section). The stressed section of each anchor bar is located at both ends of the anchor bar, and the unbonded section is located betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com