Air spring for suspension support in ground vibration test

An air spring, vibration test technology, applied in the direction of spring, spring/shock absorber, shock absorber, etc., can solve the problem of unable to meet the needs of suspension support, and achieve the effect of reducing the volume and increasing the lifting weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below.

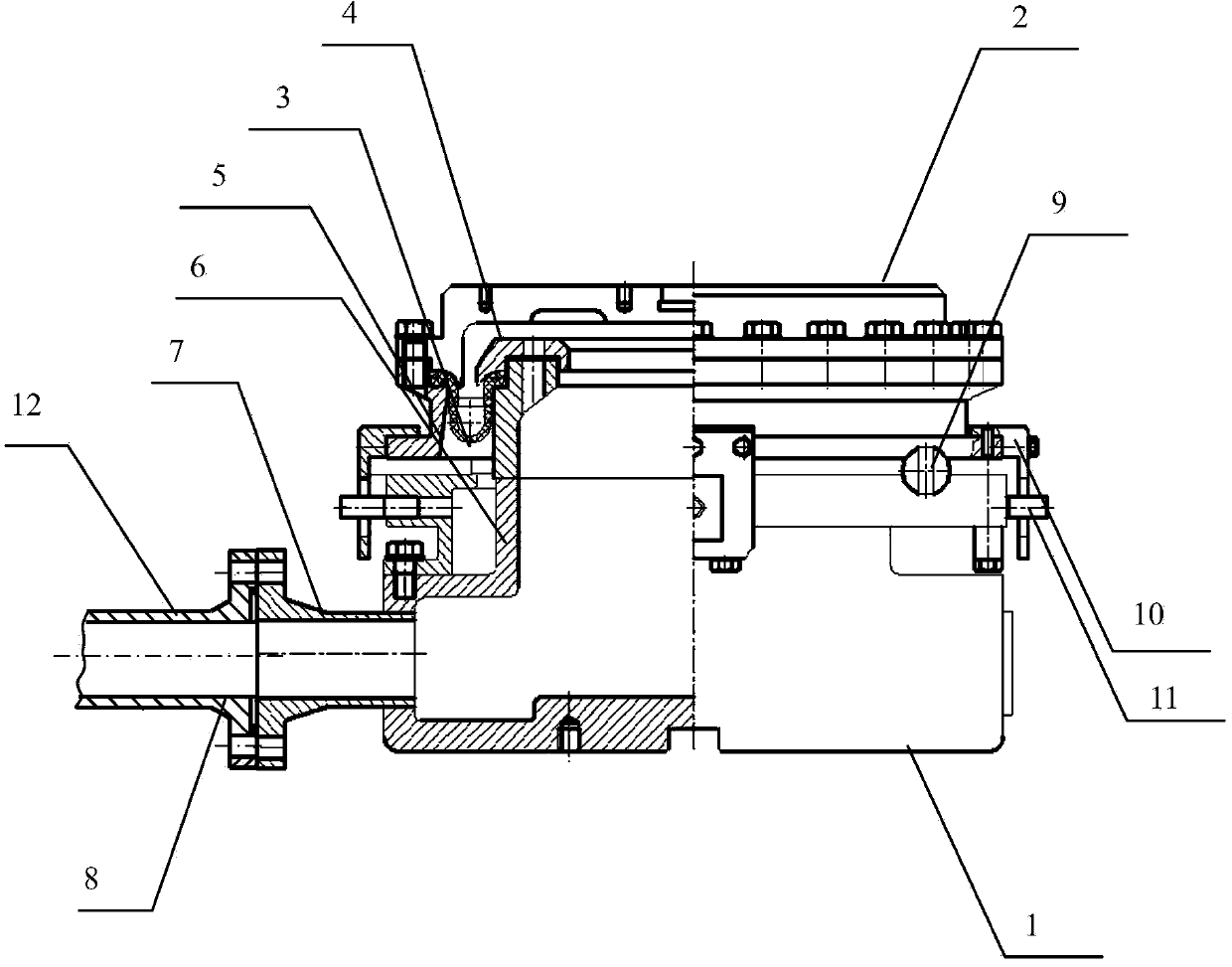

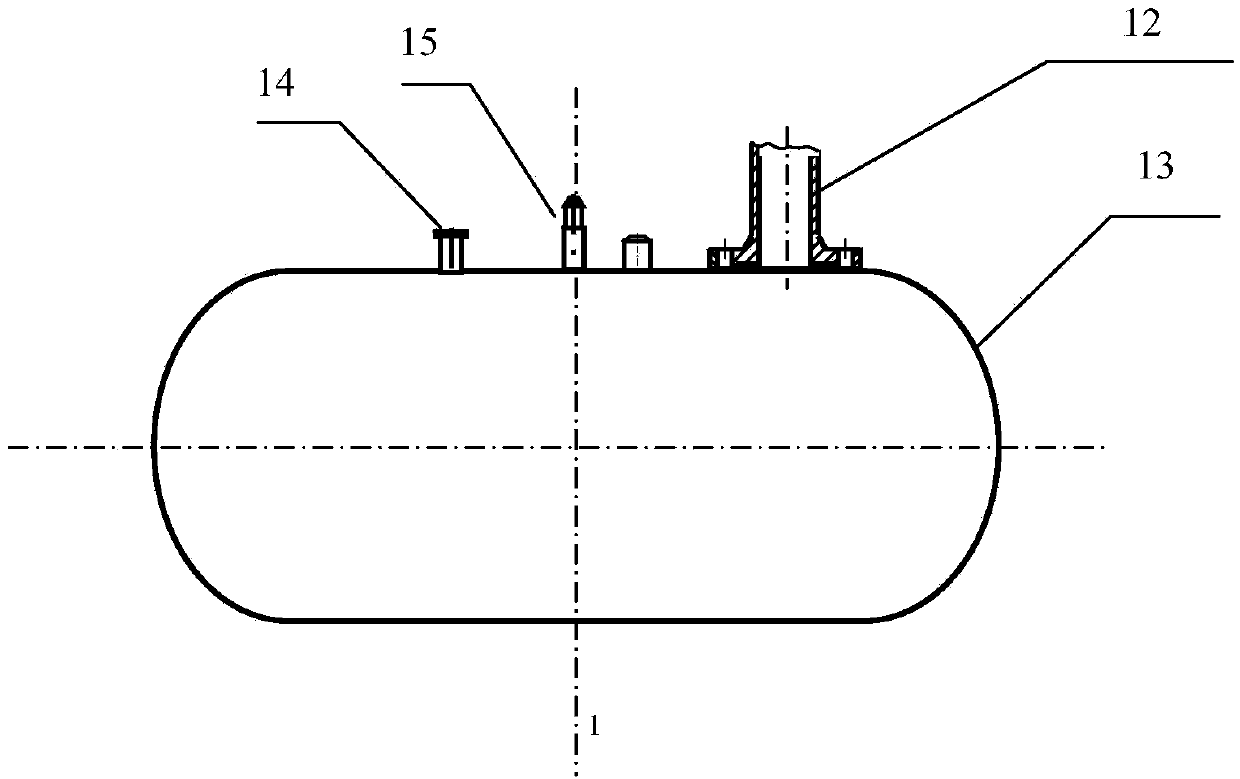

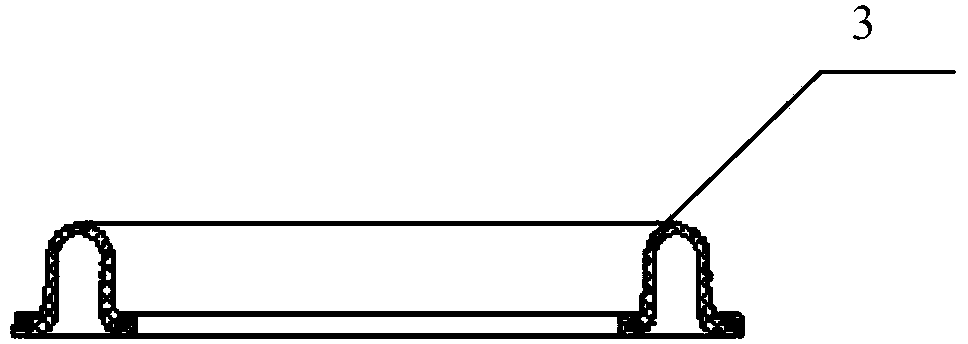

[0019] see figure 1 , figure 2 with image 3 , the air spring used for suspension support in the ground vibration test includes an air spring main body, an auxiliary air tank, a high-pressure hose, and a rubber bladder.

[0020] The main body of the air spring is connected to the auxiliary gas tank as shown in Fig. 13 through a high-pressure hose 12. The two ends of the high-pressure hose have flange discs 8, one end is connected to the air spring main body 1 by bolts, and the other end is connected to the auxiliary gas tank by bolts. Tank 13; this can reduce the support frequency of the air spring so that it meets the support requirements.

[0021] The main body of the air spring is a circular cylindrical air storage tank 1, and in the middle of its wall there is a main vent 7 to assist the gas in and out of the air tank. There are bolt holes under the bottom of the air storage tank 1, and the air s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com