Ice breaking device

A technology of ice-breaking elements and mother bombs, which is applied to weapon accessories, warheads, ammunition, etc., can solve the problems of the surrounding environment and personnel safety threats, low utilization efficiency of explosive detonation, and incomplete energy use, etc., to achieve high ice-breaking efficiency and explosives The effect of detonation energy utilization is high and the ice-breaking effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

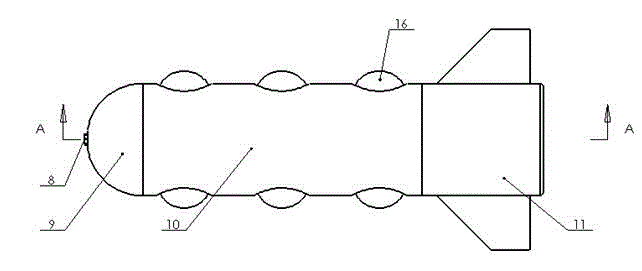

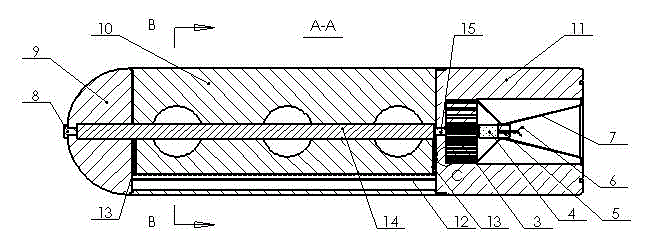

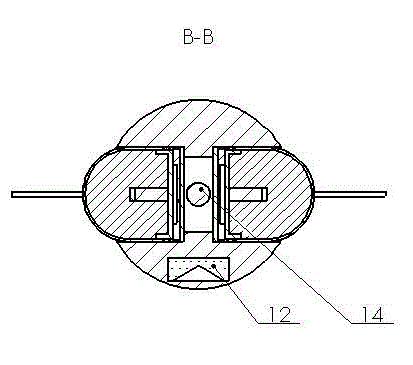

[0025] Such as figure 1 As shown, the ice-breaking device provided by the present invention includes a carrier system, a throwing system and an ice-breaking element system, wherein the carrier system includes a rocket engine and an underwater mobile carrier body, and the underwater mobile carrier body includes a carrier shell, and the front end of the carrier shell is arranged There is a hood, the front end of the hood is provided with a top cover, the rear end of the shell of the mother bomb is equipped with a balance tail device, and the rocket engine is arranged inside the balance tail device; the throwing system is set inside the shell of the mother bomb, and the ice breaking element system is a separate bullet body , embedded in both sides of the shell shell of the moving carrier body in water.

[0026] Such as figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com