Unmanned aerial vehicle and method capable of deicing on high-voltage line

A technology of high-voltage lines and drones, applied in the field of drones, can solve the problems of high line pressure, unfavorable environmental protection, etc., and achieve the effects of strong practicability, improved battery life, and convenient inspection work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

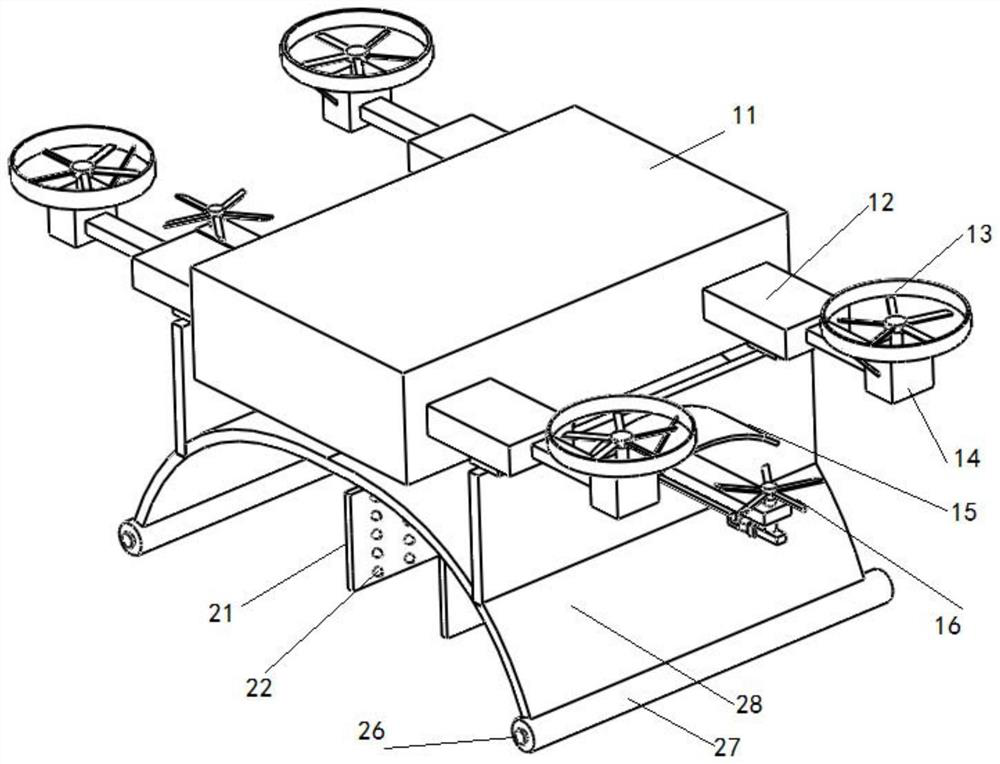

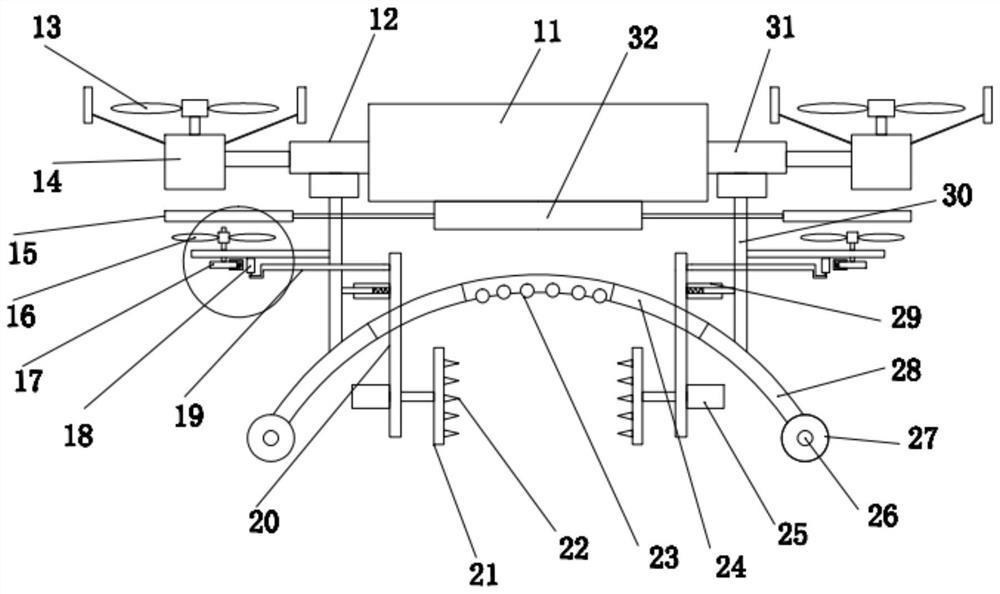

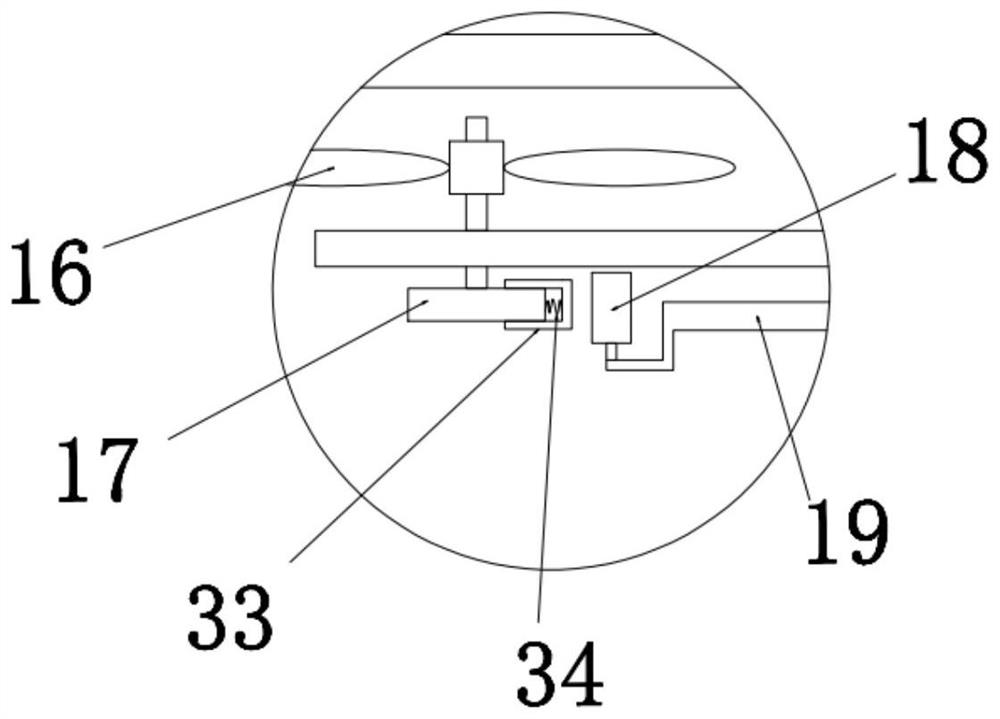

[0023] see Figure 1-Figure 4 , in the embodiment of the present invention, a kind of unmanned aerial vehicle device for maintenance and monitoring of high voltage line, comprises unmanned aerial vehicle main body 11 and the machine arm 12 that is arranged around the unmanned aerial vehicle main body 11, and each machine arm 12 end is all equipped with an engine 14. The output end of the engine 14 is provided with blades 13 for providing lifting force, and the outer side of the blades 13 is provided with an annular protective ring, and the protective ring is connected and fixed to the outer side of the engine 14 through a connecting rod, and the lower end of the arm 12 is provided with There is a suspender 30, which is connected to an arc-shaped support plate 28 in an arched structure, the lower end of the arc-shaped support plate 28 is provided with a buffer seat 27 for contacting the ground, and the end of the buffer seat 27 is provided with a The camera 26 for acquiring ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com