Combined linear flow velocity and temperature field measurement gun for flue gas in flue

A flue gas temperature, measuring gun technology, applied to measuring devices, instruments, etc., can solve the problems of difficulty in ensuring the accuracy and reliability of flow velocity data, inability to measure flow velocity at the same time, and large workload, achieving simple structure and reducing turbulence. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

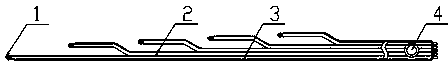

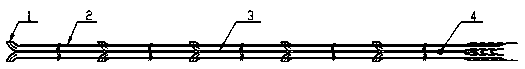

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0014] As shown in the attached picture,

[0015] A combined measuring gun for flue gas linear flow velocity and flue gas temperature field in a flue, including an S-shaped pitot tube 2 in the measuring gun and a sensor joint connecting the static pressure tube and the total pressure tube of the S-shaped pitot tube 2 and the S-shaped pitot tube. The temperature sensor 4 on the Pitot tube 2, the measuring gun is composed of more than four pairs of S-type Pitot tubes 2, and more than four pairs of S-type Pitot tubes 2 are parallel to each other. The distance between 1 is 200mm, each S-shaped pitot tube 2 is bent at 100mm from the measuring head, the bending angle is 5°-10°, after bending, the centerline of the measuring head and the centerline of the pitot tube body are parallel to each other , and the vertical distance is more than 15mm, and each S-shaped pit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com