Lens watermark defect image detection device

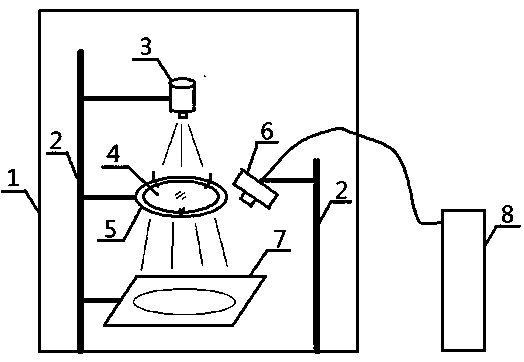

An image detection device and lens technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve problems such as uneven product quality, low accuracy of manual detection, and increased return orders, so as to improve detection efficiency , shorten the detection time and improve the detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

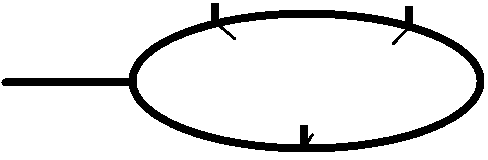

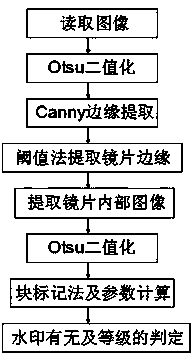

[0031] Use the above device (the camera uses a CCD of 8.8 million pixels) to take pictures of the lens with watermark defects, and obtain the original image such as Figure 4 As shown, the obtained original image is binarized using the Otus algorithm, and the obtained image is as follows Figure 5 As shown, the Canny algorithm is used to extract the lens edge image from the binarized image, and the obtained image is as follows Figure 6 As shown, then use the Otus algorithm to binarize the inside of the lens of the original image, and the obtained image is as follows Figure 7 As shown, then use the marking algorithm to mark each block, and count the number and size of the blocks. There are three blocks in the embodiment, and the number of pixels contained in each block is respectively: 498 pixels, 368 pixels, and 129 pixels. According to Relevant grading standards, when the number of pixels contained in each watermark block in the lens exceeds 100 pixels, and the number of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com