A cps-based agc logic control system and method

A technology of logic control and control method, applied in general control system, control/regulation system, adaptive control, etc., can solve the problems of frequent adjustment of generators, increased operating costs, high wear rate of system equipment, etc., and achieve enhanced overall frequency control Performance and operating economy, improved operating efficiency, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The technical scheme of the present invention is clearly and completely described below through example simulation and in conjunction with the accompanying drawings.

[0078] One, at first, introduce the method of the present invention:

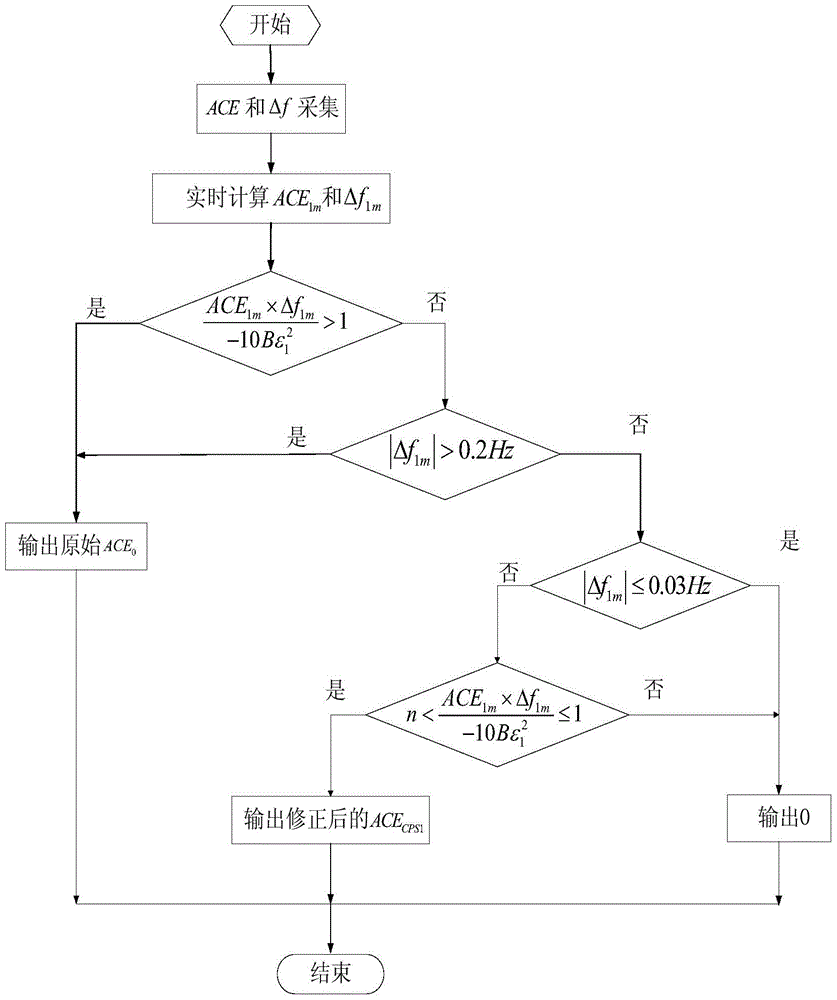

[0079] 1. AGC logic control method based on CPS1.

[0080] step 1:

[0081] According to the CPS1 standard assessment principle, the regional control deviation ACE of each control area of the interconnected grid satisfies the inequalities of (1), (2) and (3), and is accompanied by CPS 1 ≥100%, that is to meet the CPS1 standard.

[0082]

[0083]

[0084] CPS1=(2-CF 1 )×100% (3)

[0085] Where: ACE 1m Δf is the rolling average of the regional control deviation of the control area for 1 minute; 1m is the rolling average of the 1-minute frequency deviation in the control area; ε 1 is the root mean square control target value of the interconnected grid for the annual one-minute frequency average deviation, in the interconnec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com