Insulation eccentricity correction equipment for medium/high-voltage cross-linked cable

A cross-linked cable, eccentricity correction technology, applied in the direction of insulating conductors/cables, etc., can solve problems such as insulation eccentricity, achieve stable operation, save equipment investment, production raw materials, and huge practical value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

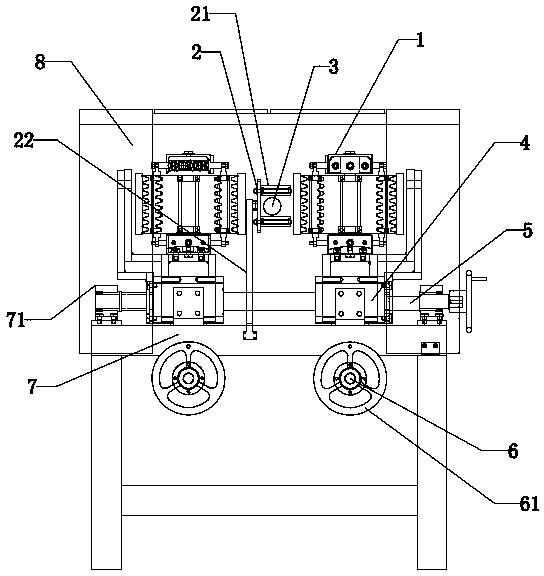

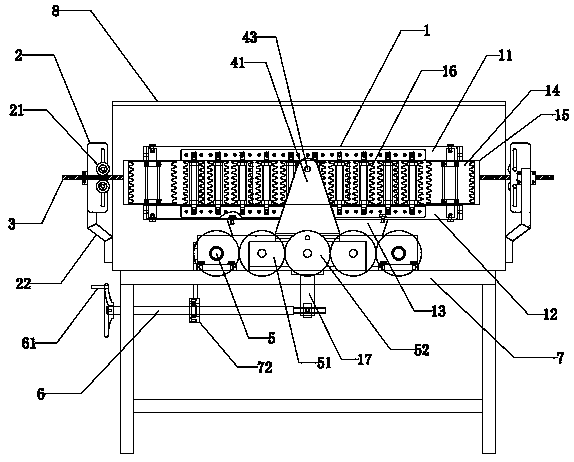

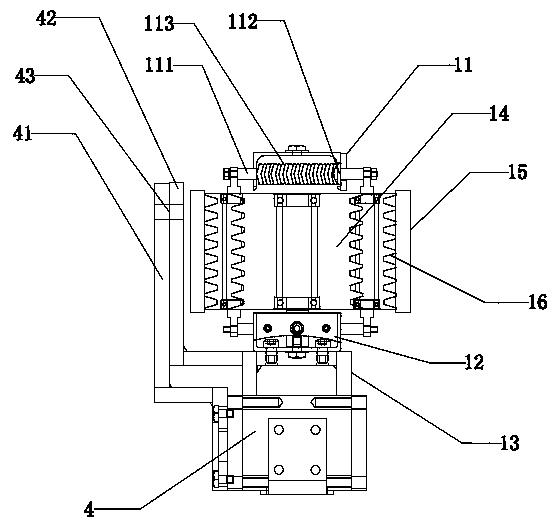

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] The structure of the present invention is as figure 1 , figure 2 As shown, taking the advancing direction of the insulated wire core 1 as the front, the insulated wire core 1 enters the equipment through the rear positioning device 2, passes through the gap between the left and right clamping devices 1, and then passes through the front positioning device 2. out. The clamping base 4 is connected to the bottom of the clamping device 1, and the clamping adjustment shaft 5 passes through the through holes of the two clamping bases 4 along the left and right directions. internal thread fit. The clamping base 4 is provided with two clamping through holes, and the two clamping adjustment shafts 5 pass through the corresponding clamping through holes of the two clamping bases 4 respectively, and the two clamping adjustment shafts 5 are connected through the transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com