Ultra-compact metamaterial wave-absorbing unit

A metamaterial, compact technology, applied in the direction of electrical components, magnetic/electric field shielding, antennas, etc., can solve problems such as difficult to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

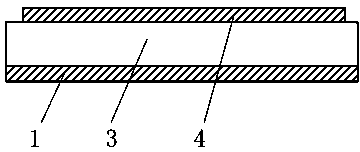

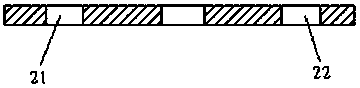

[0017] An ultra-compact metamaterial wave-absorbing unit, comprising: a first metal film 1, a rectangular dielectric layer 3 is arranged on the rectangular metal film 1, a second metal film 4 is arranged on the rectangular dielectric layer 3, and the first A metal film 1 is provided with a hollow 2, the hollow 2 is composed of a first C-shaped hollow 21 and a second C-shaped hollow 22, and the first C-shaped hollow 21 and the second C-shaped hollow 22 are arranged back to back, and the second The metal film 4 is made of a first C-shaped metal foil 41 and a second C-shaped metal foil 42, and the first C-shaped metal foil 41 and the second C-shaped metal foil 42 are arranged back to back, and the shape of the hollow 2 is consistent with that of the second metal foil. The shapes of the films 4 are similar to each other. The projection of the second metal film 4 on the first metal film 1 falls inside the hollow 2 of the first metal film 1 .

[0018] The following is the detailed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com