Flag-shaped and clamp-shaped self locking terminal

A self-locking and terminal technology, applied in the direction of contact parts, electrical components, coupling devices, etc., can solve problems such as inability to meet, the function of shrapnel is not stable enough, and achieve the effect of uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

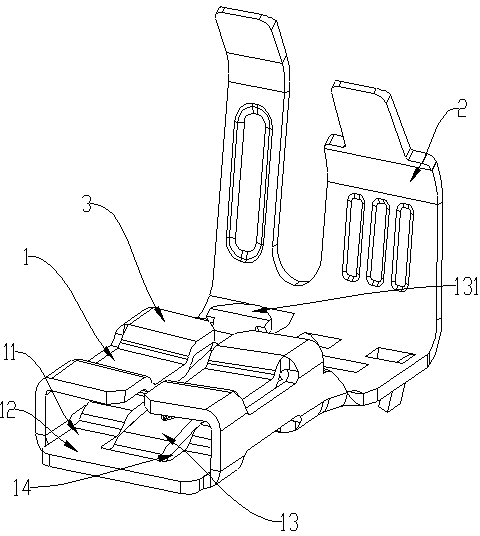

[0029] The flag-shaped clip-shaped self-locking terminal according to the present invention includes a cable connection part 2 and a wiring female terminal 3, the cable connection part 2 is flag-shaped, and the cable connection part 2 is provided with a fixing part , press the fixing part to deform and fix the cable, the female terminal 3 includes a slot 1, the upper part of the vertical side wall on both sides of the slot 1 is connected to the middle and is used to cover the male terminal The two elastic planes, the joints of the two elastic sheets 13 and the vertical side walls on both sides are cut with a rectangular notch, and corresponding to the notch, a downwardly concave recess is formed on the elastic plane, so The concave part is used to limit the moving space of the male connection terminal in the slot 1, and a gap is formed between the two elastic planes, so when the male connection terminal is inserted into the slot 1, if the space in the slot 1 is insufficient, it...

Embodiment 2

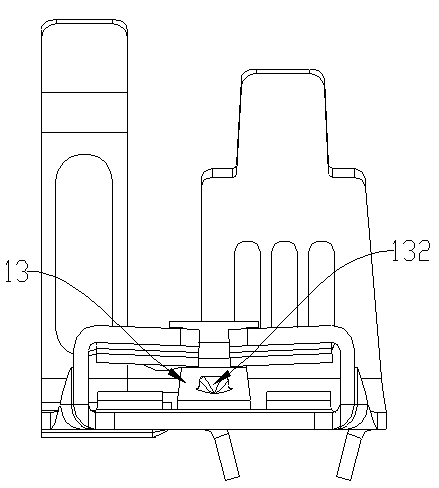

[0031] On the basis of the flag-shaped clip-shaped self-locking terminal described in Embodiment 1, the elastic piece 13 is formed with a locking part on the inner side of the slot 1, and the locking part is a protrusion 132, and the protrusion 132 extends smoothly along the insertion direction, and the protrusion 132 can be correspondingly snapped into the hole of the male connection terminal, so that the male connection terminal is locked. Without pressing the pressing end 131, the male connection terminal will not easily Shedding ensures stability during use.

[0032] There is a gap 14 between the projection of the elastic sheet 13 on the bottom 11 and the bottom 11 of the slot. The gap 14 is preferably 0.36 mm on one side, which can ensure that the coating is evenly and completely plated on the elastic sheet 13 In addition, the area of the bottom 11 will not be too small because the gap 14 is too large. As another alternative embodiment, the gap 14 can also be 0.35-0.40m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com