PCB thermal pad

A technology for heat dissipation pads and pads, applied in the direction of electrical connection of printed components, printed circuit components, etc., can solve the problems of too fast heat dissipation, pad falling off, and high temperature, so as to reduce rapid heat dissipation and full current flow. , the effect of sufficient heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing and embodiment:

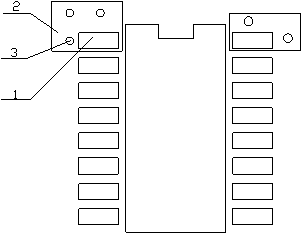

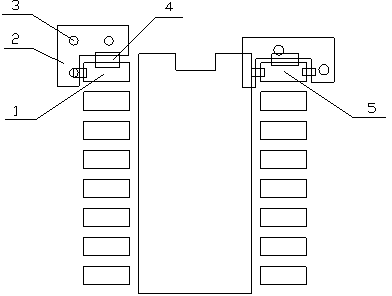

[0021] Such as figure 1 , figure 2 As shown, a PCB heat dissipation pad includes an IC power pad 1, an IC ground pad 5, and a conductive bridge 4. Both the IC power pad 1 and the IC ground pad 5 are square, and the IC power pad At least one side of 1 is connected to the power supply copper skin 2 on the adjacent PCB through a conductive bridge 4, and at least one side of the IC ground pad 5 is connected to the ground copper skin on the adjacent PCB through a conductive bridge 4 , at least one via hole 3 is provided on both the power supply copper skin 2 and the ground copper skin.

[0022] A conductive bridge is set between the ground pad of the IC power supply and the copper skin. In the case of sufficient power supply, the heat loss added to the pad is slowed down, and the damage to the pad caused by heating the pad for a long time d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com