Ceramic steamed bun making machine

A steamed bun machine and ceramic technology, which is applied in the fields of dough forming machinery or equipment, baking, food science, etc., can solve the problems of metallic taste, noodle flavor and chewiness gap, etc., and achieve easy cleaning, meet dietary requirements, and not easy to stick face effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

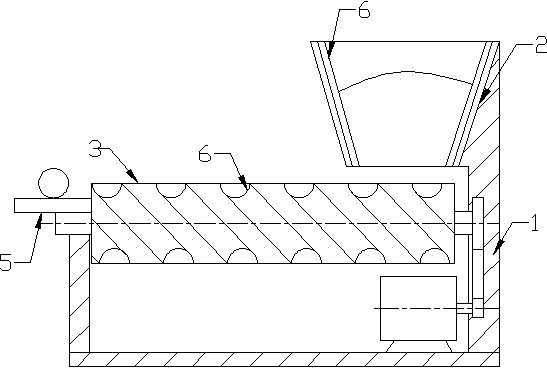

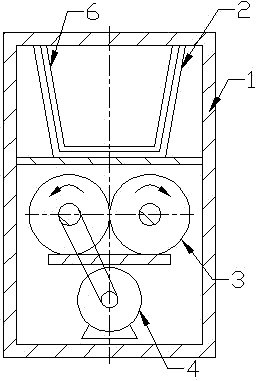

[0009] Such as figure 1 and figure 2 shown. The present invention provides a ceramic steamed bun machine, comprising a frame 1, a noodle funnel 2 on the top of the frame 1, the bottom of the noodle funnel 2 facing one end of two helical columns 3, the surfaces of the two helical columns 3 have hemispherical helical grooves, The motor 4 drives the two helical columns, one forward and one reverse, and the other end of the helical column 4 is provided with a connecting ball plate 5, which is characterized in that the surface funnel 2, the screw column 3 and the connecting ball can be touched by the dough. There are ceramic coatings 6 on the surfaces of the boards 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com