Methanation reactor

A methanation reactor and methane technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of increased equipment investment and energy consumption, complex manufacturing process, high reactor cost, etc., to achieve equipment investment and operating costs Low cost, reduce manufacturing cost, save preheating energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

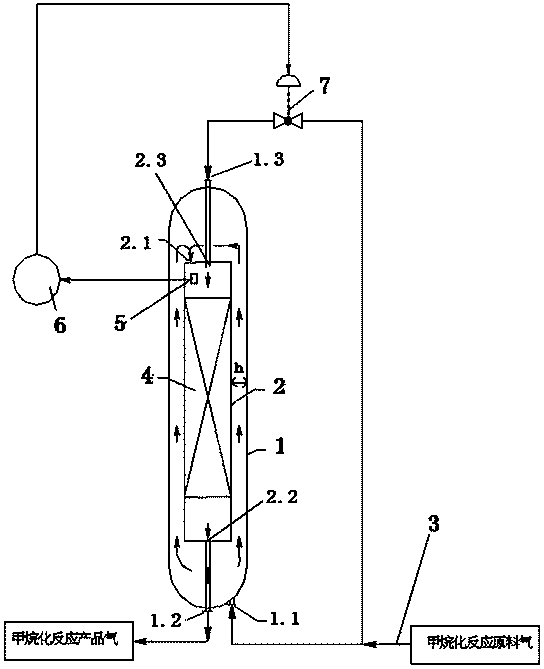

[0019] Below in conjunction with accompanying drawing, the present invention will be further explained:

[0020] The bottom of the outer shell 1 is provided with an air inlet 1.1 and an outlet gas 1.2, and the outer shell 1 is also provided with an inner shell 2 filled with a methane catalyst bed 4, and the inner shell 1 The air inlet 2.1 of the body 2 is located at the top of the inner shell 2, and the air outlet 2.2 is located at the bottom of the inner shell 2 and is connected with the air outlet 1.2 of the outer shell 1. The distance between the inner shell 2 and the outer shell 1 is not less than 0.01m, and the optimal distance is 0.08-0.2m. The top of the outer shell 1 is also provided with a bypass air inlet 1.3, and the bypass air inlet 1.3 of the outer shell 1 is connected with the bypass air inlet 2.3 on the top of the inner shell 2. The air inlet 1.1 of the outer shell 1 and the bypass air inlet 1.3 are all connected to the raw material gas pipe 3, and the pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com