A method for reducing energy consumption of ethylene plant

An ethylene device and energy consumption technology, which is applied in the chemical industry, non-catalytic thermal cracking, climate sustainability, etc., can solve the problems of small discharge, loss of function, and less discharge, and achieve reduction of preheating energy consumption, Effect of reducing energy consumption and improving recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

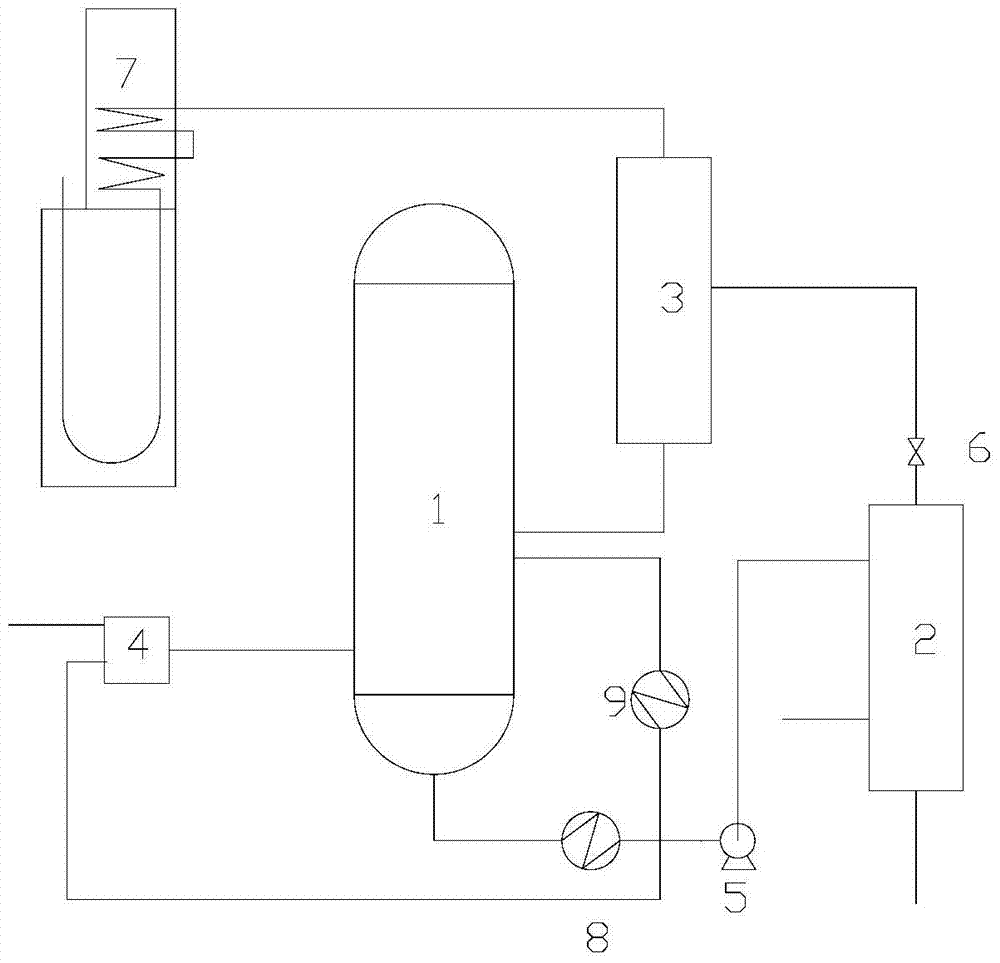

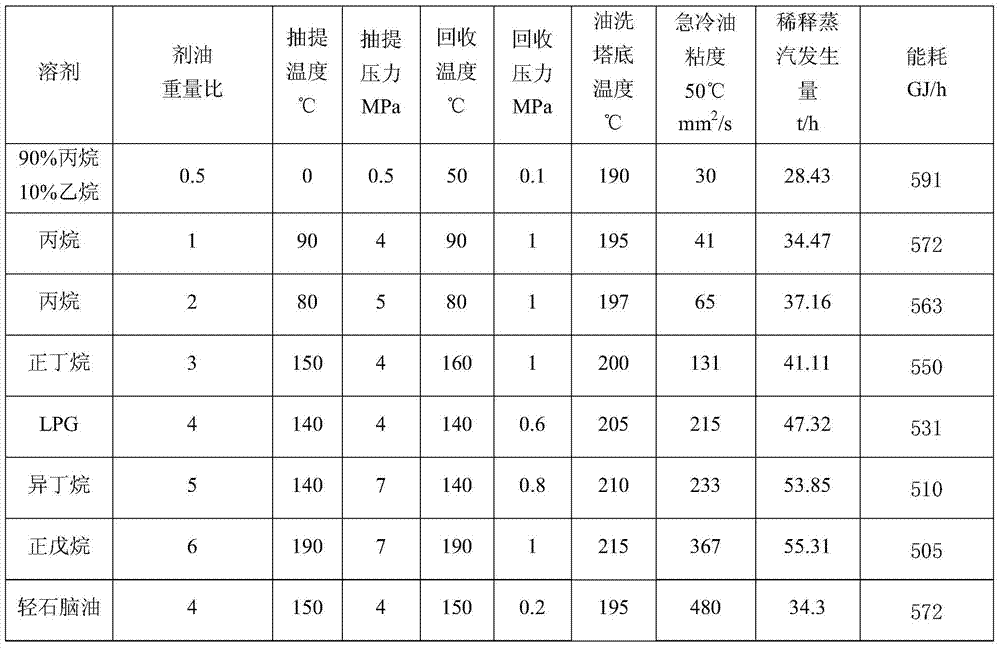

[0033] An ethylene plant has an annual output of 200k / a, an annual operation of 8000h, and an ethylene output of 25t / h. The high-temperature cracked gas at the outlet of the cracking furnace (contains components from H2 to cracked fuel oil, and also includes dilution steam), after being cooled by the waste heat boiler, the total amount is 147t / h, and enters the quencher to directly contact with the quenching oil ,cool down. The cooled pyrolysis gas and quenching oil enter the oil washing tower together for oil and gas separation, and the circulating quenching oil is drawn out from the tower kettle and enters the dilution steam generator to generate dilution steam. After the quench oil is cooled, it is divided into three paths, one path goes to the cracking furnace quencher; one path passes through the process water preheater and then returns to the oil washing tower; the other path enters the extraction tower and undergoes solvent extraction, and the asphalt is mainly removed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com