Device for carrying out heat exchange between gas and solid particulate matters

A solid particle, one-stage heat exchange technology, applied in heat exchanger types, direct contact heat exchangers, lighting and heating equipment, etc., can solve the problem of poor preheating effect, uneven preheating of powder materials, spreading The machine cannot guarantee the complete dispersion of powder, etc., so as to avoid loss, reduce preheating energy consumption, and improve preheating yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

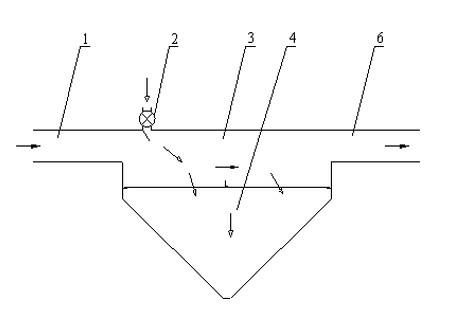

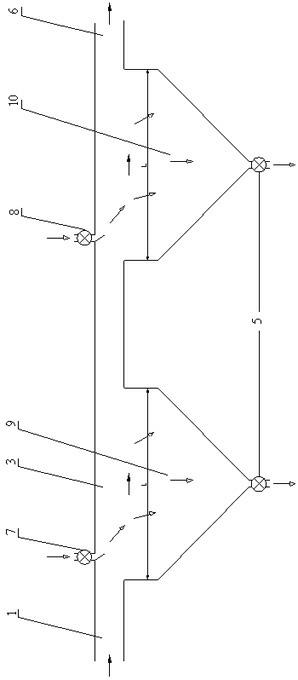

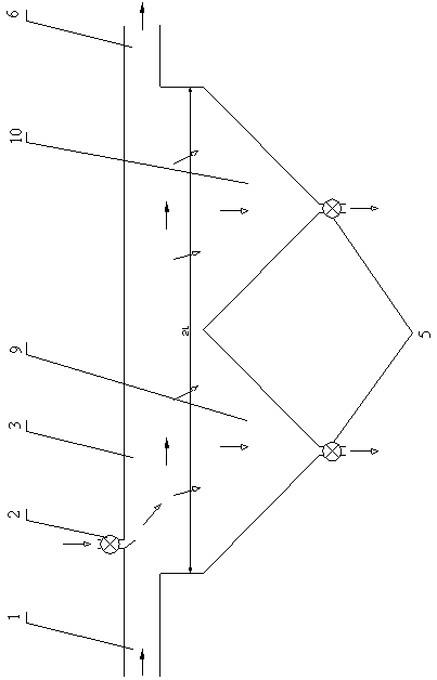

[0039] The device for heat exchange between gas and solid particles of the present invention includes at least one stage of heat exchange unit, each stage of the heat exchange unit includes an airflow channel 3, and an air inlet 1 is provided at one end of the airflow channel 3 , The other end is provided with an air outlet 6; the air flow channel 3 is arranged horizontally; at the bottom of the air flow channel 3, a settling collection hopper 4 extends downward, and the settling collection hopper 4 is in communication with the air flow channel 3; At least one feed port 2 is provided on the top of the air flow channel 3 and above the communication opening of the settling collection hopper 4 and the air flow channel 3, and the feed port 2 is located close to the settling collection hopper 4 The air inlet 1 is provided on one side; along the flow direction of the gas, the air outlet 6 of the airflow channel 3 of the previous heat exchange unit communicates with the air inlet 1 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com