A kind of preparation method of magnetic uranium adsorbent

An adsorbent and magnetic technology, which is applied in the field of preparation of magnetic hydrated calcium silicate uranium adsorbent materials, can solve the problem of uneven distribution of magnetic particles, no reports of magnetic hydrated calcium silicate uranium adsorbents have been found, and the influence of hydrated calcium silicate Structure and morphology and other issues, to achieve the effect of excellent adsorption performance, fast adsorption speed, and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

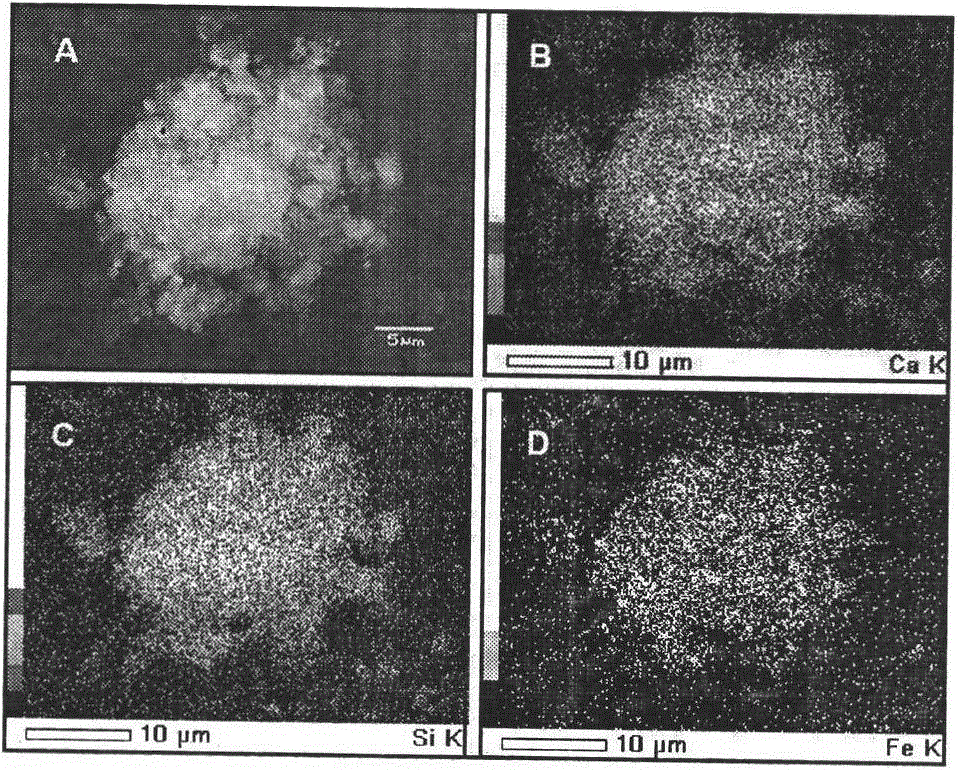

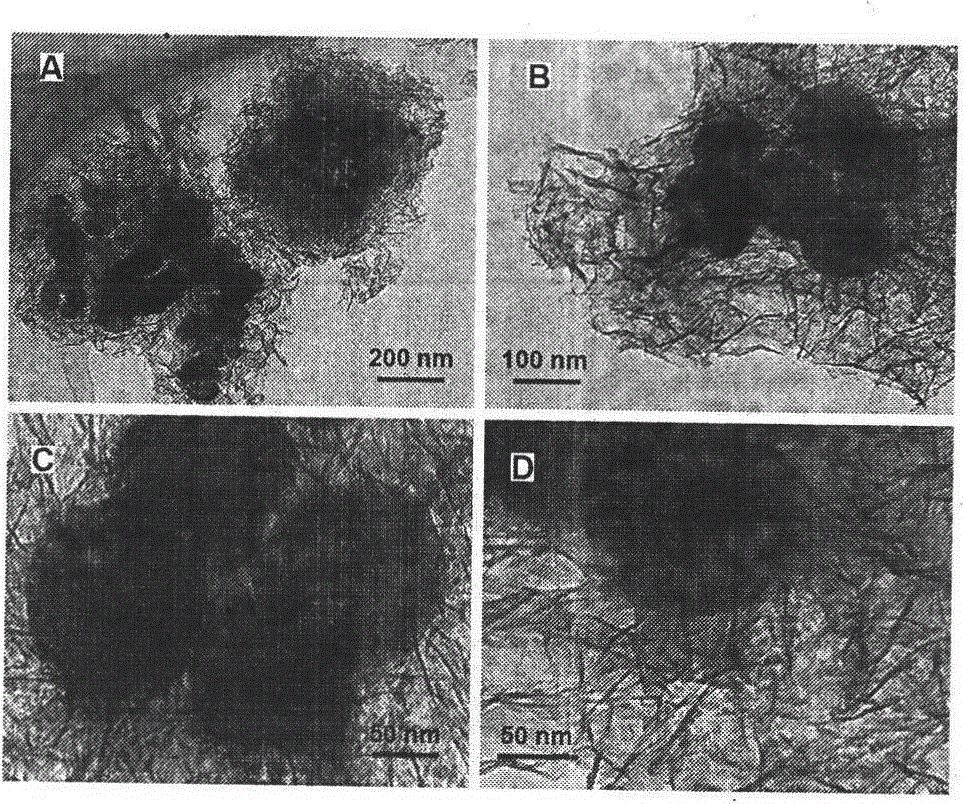

[0018] (1) 0.2g of Fe with an average particle size of less than 300nm 3 o 4 (50-80emu / g) into 0.080-0.095M80mL HCl ultrasonic (20-40KHz) 15-30min, magnetic separation, wash with deionized water until neutral, pour out deionized water, add 40mL deionized water and 160mL anhydrous Ethanol, under ultrasonic (20-40KHz) and stirring conditions, add 2mL of 28% ammonium hydroxide solution, further dropwise add 0.28-0.30mmol ethyl orthosilicate, stir for 7-10h, magnetic separation, 50-100mL deionized water Wash 3-5 times to obtain the intermediate.

[0019] (2) The preparation process of this step is completed under ultrasonic (20-40KHz) and stirring conditions, and 200mL of 15-30mmol / L Ca(NO 3 ) 2 Solution, 10-30min, add 1mL of 1M NaOH solution, drop 4.00-4.50mmol ethyl orthosilicate in 20-200min, react for 30min, magnetically separate, wash 3-5 times with 50-100mL deionized water to obtain magnetic adsorbent .

[0020] (3) Place the sample in a freezer, freeze at -40--80°C for...

Embodiment 2

[0023] The preparation method of the uranium adsorbent of embodiment 2 is basically the same as that of embodiment 1, and the difference is: step (1) 0.2g average particle diameter is less than 300nm Fe 3 o 4 (40-80emu / g) into 0.095M80mL HCl ultrasonic (20KHz) 15-30min, magnetic separation, washed with deionized water until neutral, deionized water, add 40mL deionized water and 160mL absolute ethanol, in ultrasonic (20KHz) and stirring condition, add 2mL of 28% ammonium hydroxide solution, further dropwise add 0.29mmol ethyl orthosilicate, stir for 7h, magnetically separate, wash 5 times with 50mL deionized water to obtain the intermediate.

Embodiment 3

[0025] The preparation method of the uranium adsorbent of embodiment 3 is basically the same as that of embodiment 2, the difference is: step (2) the preparation process of this step is completed under ultrasonic (40KHz) and stirring conditions, and 200mL22mmol / L of Ca is added to the intermediate (NO 3 ) 2 Solution, 10min, add 1mL of 1M NaOH solution, add 4.50mmol ethyl orthosilicate dropwise within 30min, react for 30min, magnetically separate, wash 5 times with 50mL deionized water, and obtain a magnetic adsorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com