A Discrete Flexible Mold

A flexible mold and punch technology, applied in the field of rapid forming molds for curved plates, can solve the problems of reduced forming accuracy of parts and unsmooth plate surface, and achieve the effects of fast shape adjustment, simple and practical method, and low construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings.

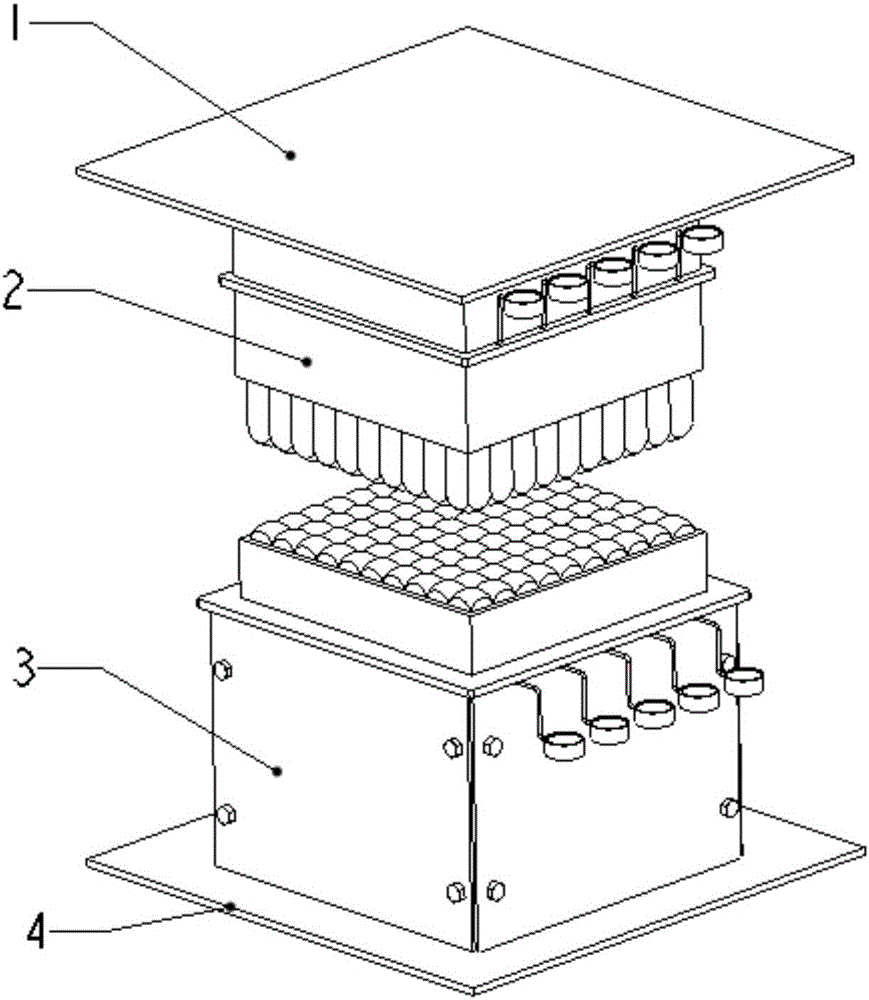

[0038] refer to figure 1 , a discrete flexible mold, including two parts, the upper discrete mold 2 and the lower discrete mold 3, the upper discrete mold 2 is connected with the upper slide 1 of the press, the lower discrete mold 3 is combined with the base 4 of the press, and the upper discrete mold 2 It does not contain electric push rod 5 and is light in weight, so it is placed on the upper part and is easy to move. The lower discrete mold 3 contains electric push rod 5 and is heavy in weight.

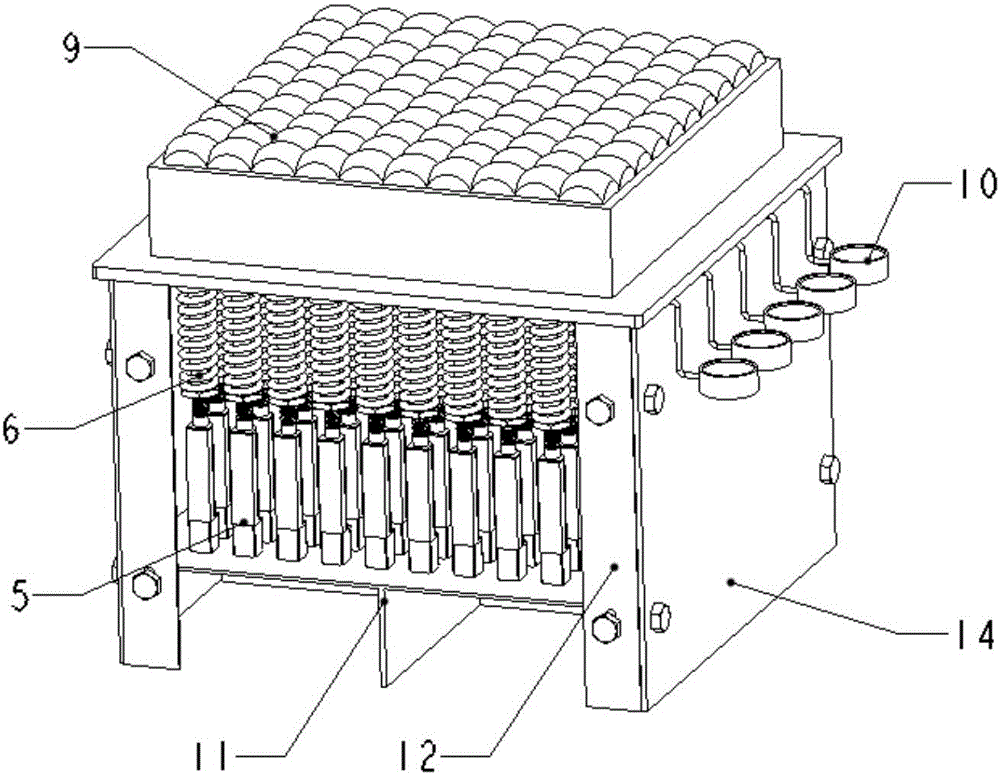

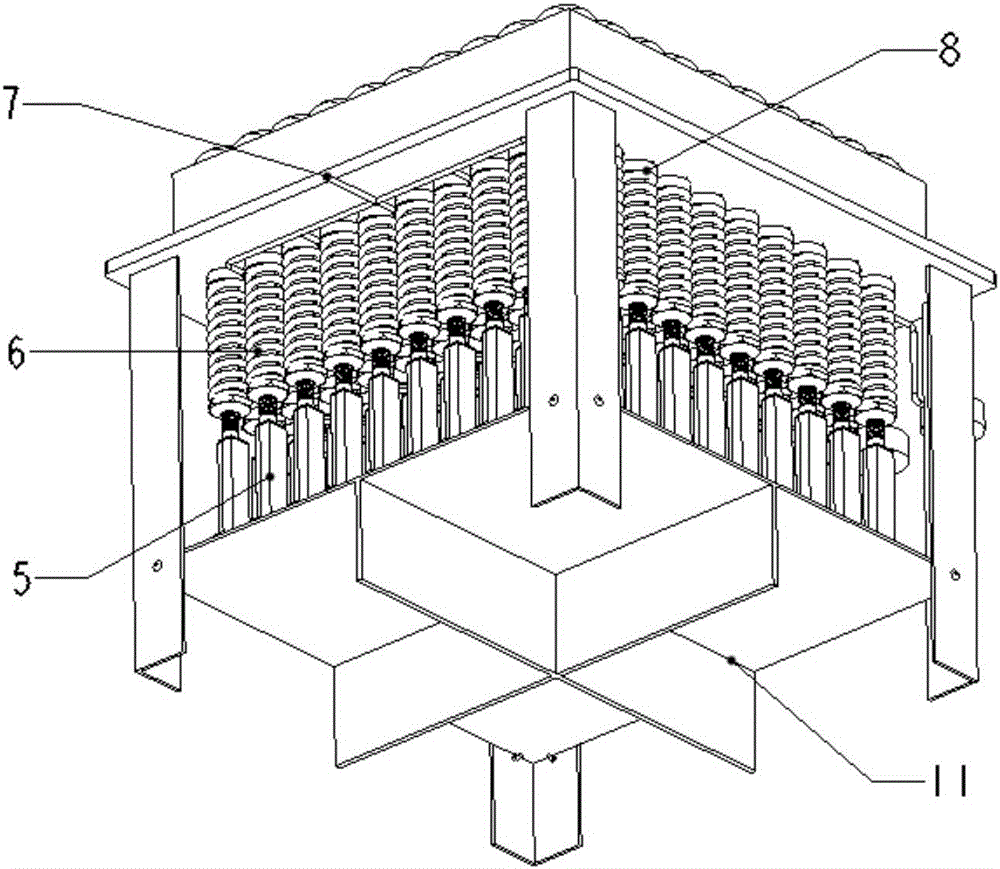

[0039] refer to figure 2 and image 3 , the lower discrete mold 3 includes a lower mold support 12, a first hydraulic tensioner 8 is installed in the round hole of the top support plate of the lower mold support 12, and the first hydraulic tensioner 8 passes through its inner sleeve 8-4 The outer flange is fixed on the lower mold support 12, the oil supply of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com