Angle grinder reluctance motor

A magnetoresistive, angle grinder technology, applied in the shape/pattern/structure of magnetic circuit, static parts of magnetic circuit, shape/pattern/structure of winding conductor, etc., can solve the problems of complex frequency conversion technology and high cost, achieve The effect of large magnetic flux, easy heat dissipation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

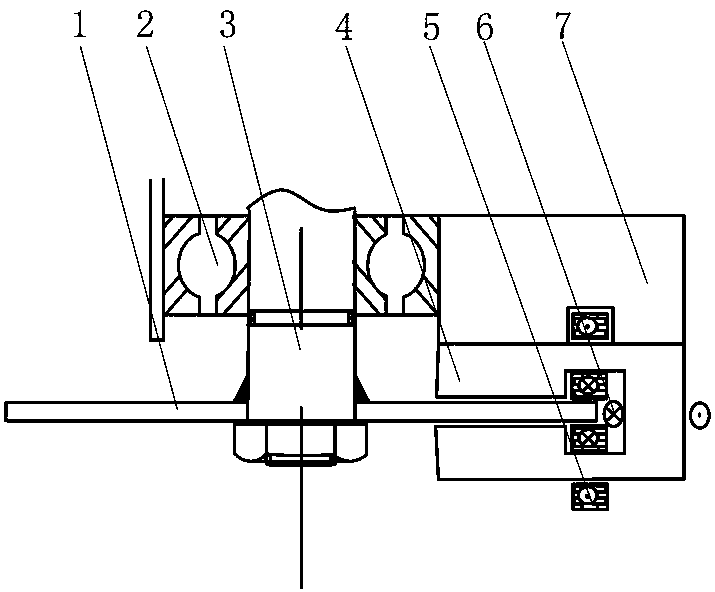

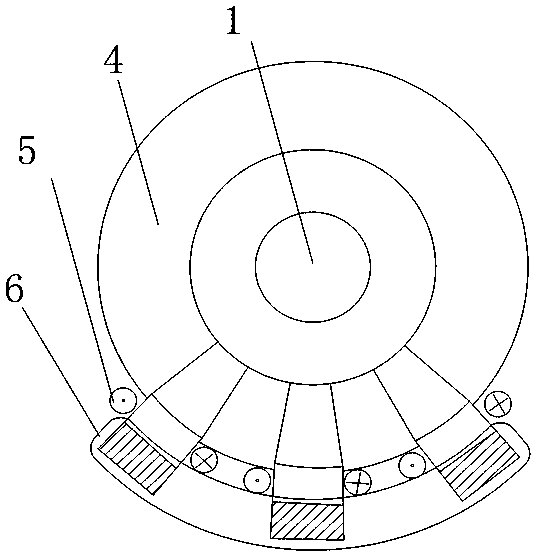

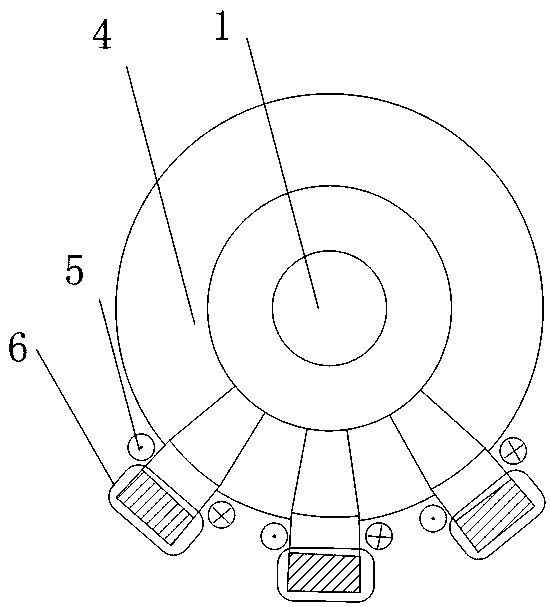

[0023] figure 1 It is a longitudinal sectional view of an angle grinder reluctance motor of the present invention. Among them, 1 grinding plate, 2 bearings, 3 shafts, 4 stator cores, 5 armature windings, 6 excitation windings, and 7 shells. A reluctance motor for an angle grinder, characterized in that 6 fan-shaped through holes are evenly distributed on the circumference of the grinding disc fixed on the shaft, and there are grinding disc ribs made of magnetically conductive material between the two fan-shaped through holes ; The shell is connected to the shaft through the bearing.

[0024] The stator core is composed of three "匚"-shaped sub-stator cores. Each sub-stator core is symmetrically distributed on both sides of the grinding plate and fixed on the shell. The difference between adjacent sub-stator cores is 40 degrees along the circumferential direction; each sub-stator core There is an armature pole on both sides facing the axis, and the end face of the armature pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com