Exhaust gas turbine-driven reluctance motor

A technology of exhaust gas turbine and reluctance motor, which is applied in the field of vehicle engineering to achieve the effect of less poles, easy heat dissipation and quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

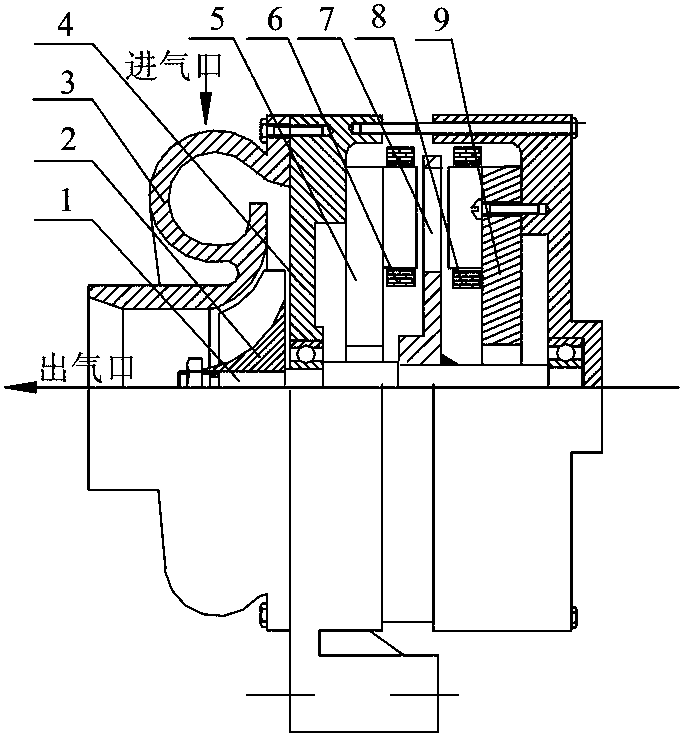

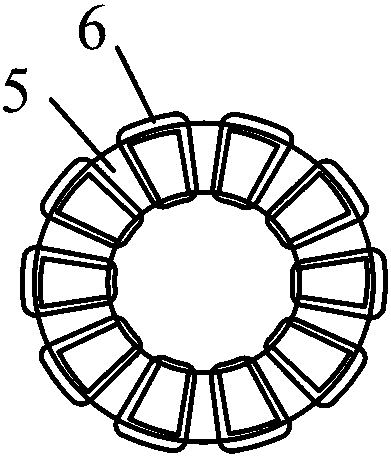

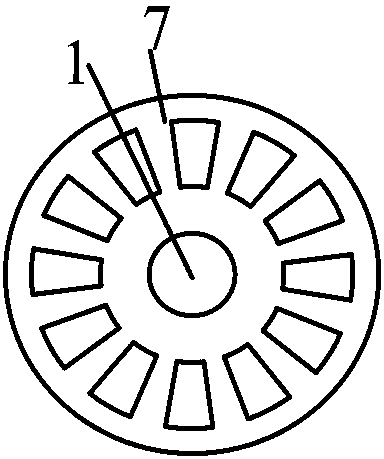

[0024] figure 1 It is a longitudinal sectional view of a reluctance motor driven by an exhaust gas turbine. Among them, 1 shaft; 2 exhaust gas turbine; 3 exhaust gas turbine shell; 4 motor casing; 5 first armature core; 6 first armature coil; 7 rotor core; 8 second armature coil; 9 second armature core.

[0025] A reluctance motor driven by an exhaust gas turbine, characterized by:

[0026] The exhaust gas turbine and the rotor core are fixed on the shaft; the first armature core, the rotor core and the second armature core are all disc-shaped, and the first armature core and the second armature core are symmetrically located on the axis of the rotor core to both sides and fixed on the motor housing;

[0027] There are 6k fan-shaped through holes evenly distributed on the circumference of the rotor core, k is a positive integer greater than 1; the first armature core and the second armature core have 5k uniformly distributed fan-shaped protruding electric poles on the side f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com