Intelligent control method of hydraulic press

An intelligent control, hydraulic press technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of low control accuracy and low safety factor, and achieve the effect of safe operation process, high control safety factor, and improved accuracy and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention will be further described by embodiment.

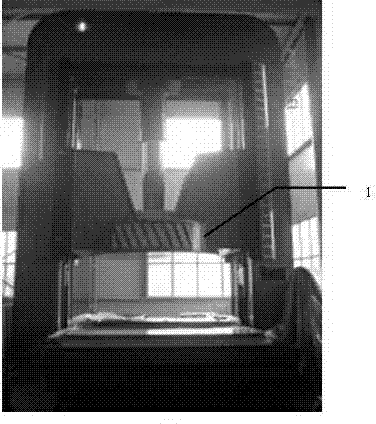

[0029] In this example, 400t hydraulic press equipment is used for axially compressing and shaping the coil in the production of shell-type reactors.

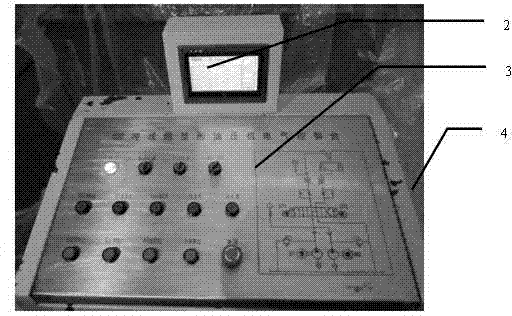

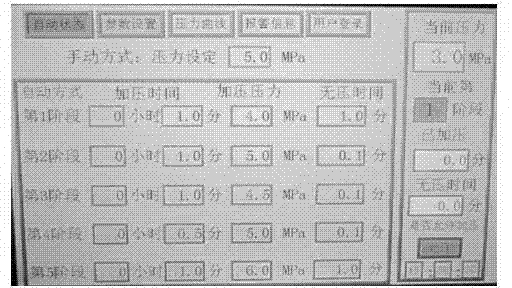

[0030] The hydraulic press intelligent control system is used for axial compression and shaping of the coil in the production of shell-type reactors. The system includes hydraulic press table 1, touch screen 2, console 3, PLC controller 4 and pressure sensor 5; the touch screen is installed in the control On the table, the PLC controller is installed inside the console; the hydraulic press table is provided with a pressure sensor, the pressure sensor is connected with the PLC controller, and the PLC controller is connected with the touch screen and the console.

[0031] The console is provided with a plurality of buttons, intermediate relays and indicator lights, and the buttons, intermediate relays and indica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com