joystick assembly

A joystick and assembly technology, applied in the field of construction machinery operating mechanisms, can solve the problems of large control resistance, reduced ability of pipe joints to bear tensile force, deformation of outer pipe steel wires, etc., so as to improve load efficiency and service life, reduce Resistance and idle travel, the effect of solving early wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

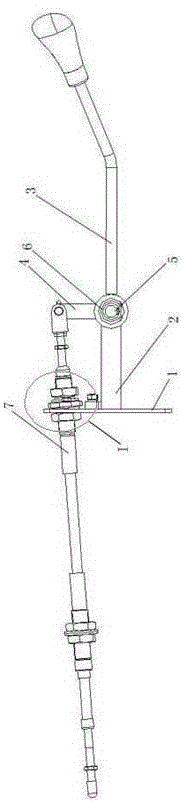

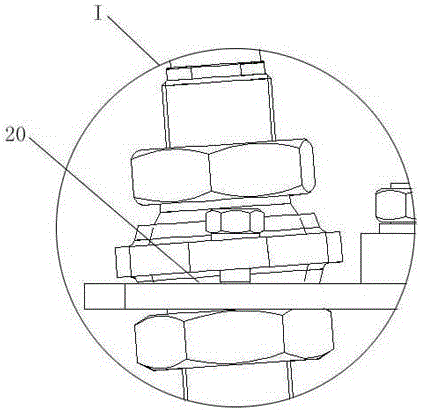

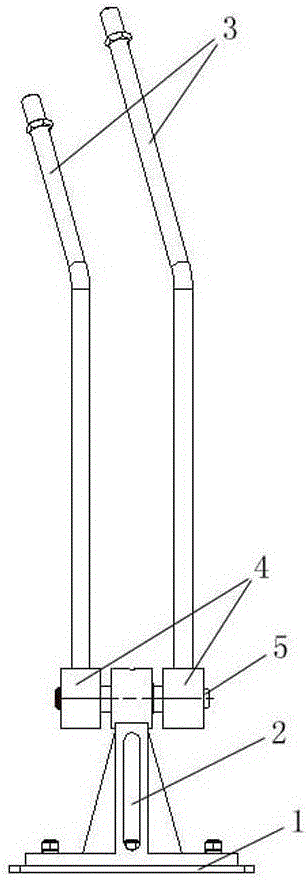

[0024] like Figure 1~Figure 4 As shown, the joystick assembly of this embodiment includes a base 1, a bracket 2, a joystick 3, a rocker arm 4, a main shaft 5, a bearing 6, and a flexible shaft 7. The bracket 2 is fixedly connected to the base 1, and the main shaft 5 Installed on the bracket 2, it is characterized in that: the joystick 3 is fixedly connected to the rocker arm 4, one end of the rocker arm 4 connected to the joystick 3 is connected to the main shaft 5 through a bearing 6, and the flexible shaft 7 is connected to the rocker arm 4 The other end is connected, the other end of the flexible shaft 7 passes through the base 1, and the connection mode between the flexible shaft 7 and the base 1 is a hemispherical hinge;

[0025] The rocking arm 4 is provided with a hole 8 matching with the end of the joystick 3, and the connection mode between the joystick 3 and the rocking arm 4 is: the end of the joystick 3 is matched with the hole 8 of the rocking arm and then welded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com