Preparation method for deeply removing cadmium from zinc sulfate for feed

A technology of zinc sulfate and zinc sulfate solution, applied in directions such as zinc sulfate, can solve the problem of high cost, and achieve the effects of low purchase cost, simple and stable operation, and easy raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

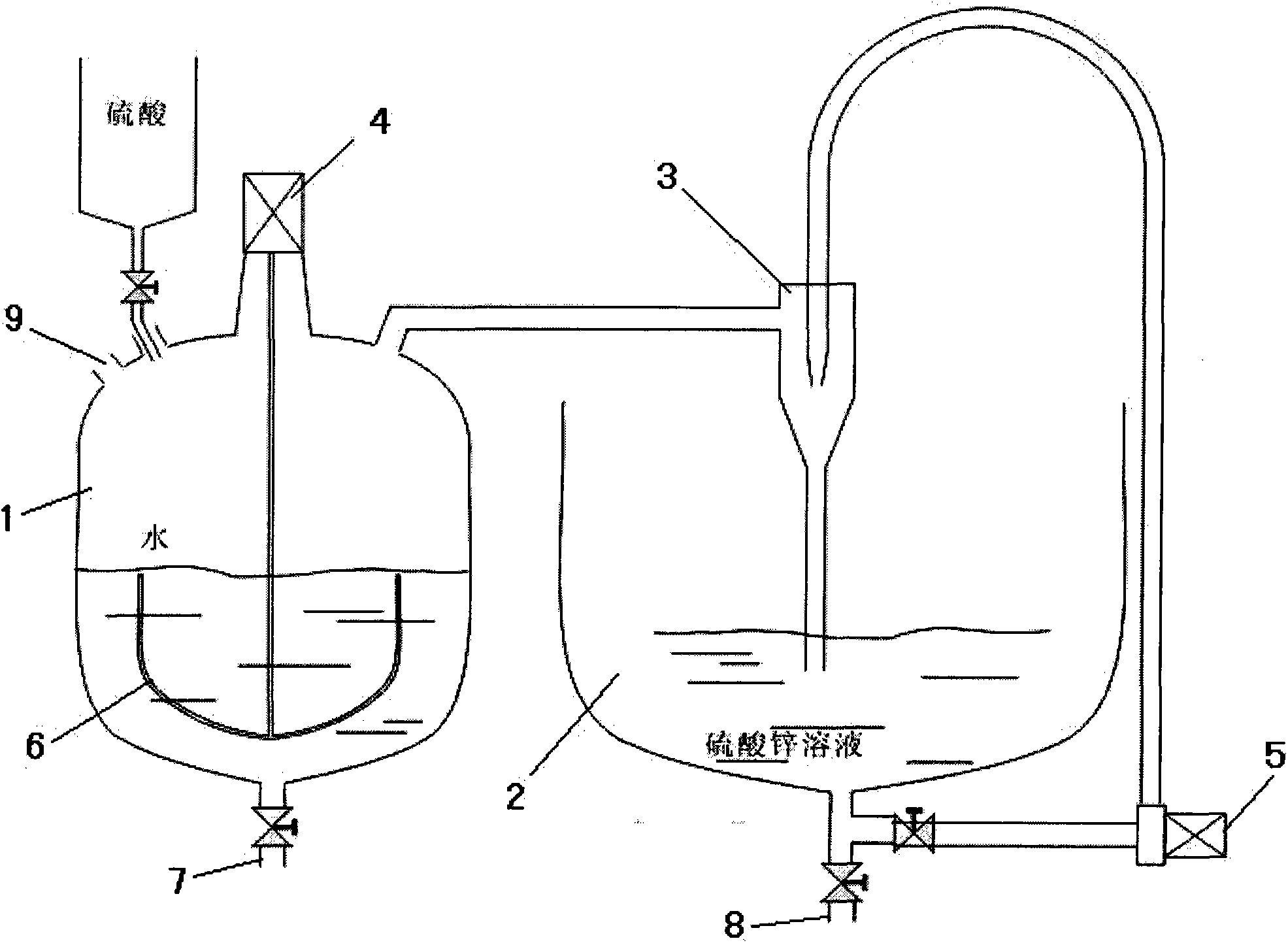

[0022] Please see attached figure 1 Shown, a kind of preparation method of zinc sulfate deepness removal cadmium for feed, described preparation method uses 500L reactor 1, the reaction pool 2 of 3000L, water jet vacuum pump 3, motor 4 and water pump 5, described motor 4 Set above the reactor 1, the reactor 1 is provided with a stirring paddle 6 connected to the motor 4, the reactor 1 is connected to the water jet vacuum pump 3 through a pipeline, Described water jet vacuum pump 3 is arranged on the top of described reaction tank 2, and described water jet vacuum pump 3 is connected with described water pump 5 through pipeline, and described water pump 5 is connected with described reaction tank 2 through pipeline. The bottom is connected, and the preparation method at least includes the following steps:

[0023] Step 1: The pH value of the zinc sulfate solution is adjusted to 2.5 by an acidity meter, and the zinc sulfate solution is added into the reaction tank 2, and the zi...

Embodiment 1

[0036] Take zinc sulfate solution, the temperature of the zinc sulfate solution is 30°C, add a small amount of sulfuric acid to adjust the pH value to 2.5. Carry out the cadmium removal reaction according to the above operation process, and the reaction pool 2 will have orange-yellow turbidity (cadmium sulfide). Continue to operate, and the reaction pool 2 will produce rotten egg smell (hydrogen sulfide). Stop the cadmium removal operation, release the zinc sulfate solution in the reaction tank 2 from the discharge port, and perform pressure filtration, take the filtered zinc sulfate solution and concentrate, and cool to obtain zinc sulfate crystals, check The cadmium content of this zinc sulfate crystal is 0.6ppm, which meets the expected requirement.

[0037] In summary, the present invention can effectively remove cadmium in zinc sulfate for feed, and it is most intuitive to control the pH of the solution to 2.5, and the effect is the best, and the separated cadmium does no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com