A kind of preparation method for the polyester resin of non-frost type powder coating

A polyester resin, powder coating technology, applied in powder coatings, polyester coatings, coatings, etc., can solve problems affecting the appearance and performance of coatings, and achieve good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

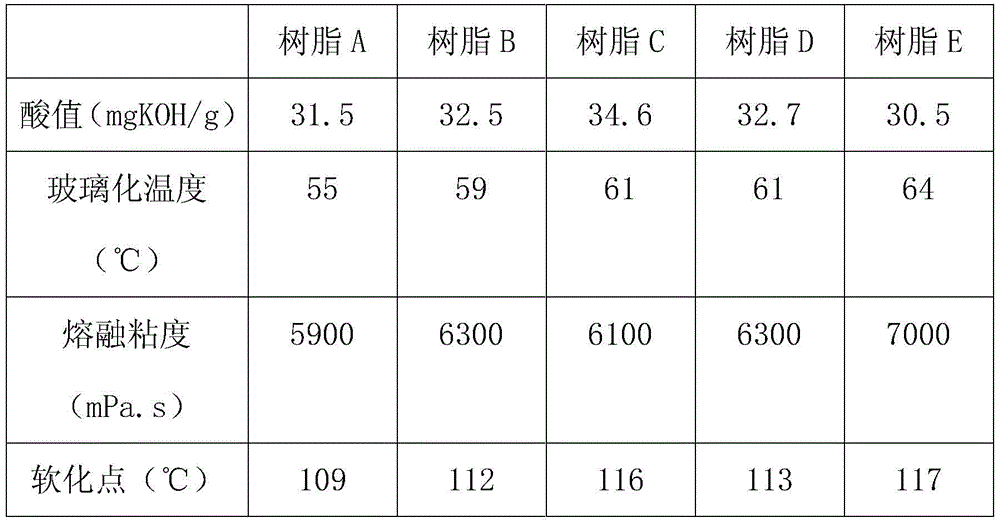

Examples

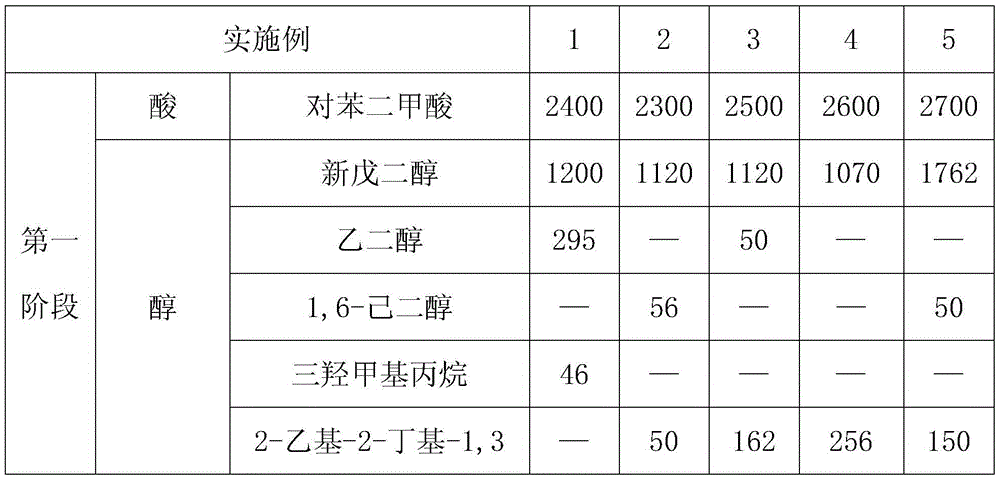

Embodiment 1

[0022] Preparation of frost-free polyester resin:

[0023] The first stage: Put the formula amount of alcohol into the reaction kettle, heat to 110°C, wait until the alcohol is completely melted, stir at a speed of 130r / min, then put in the formula amount of acid and esterification catalyst, heat up to 170°C, at 5°C / 30min heating rate to 245°C, maintain acid value 8mgKOH / g;

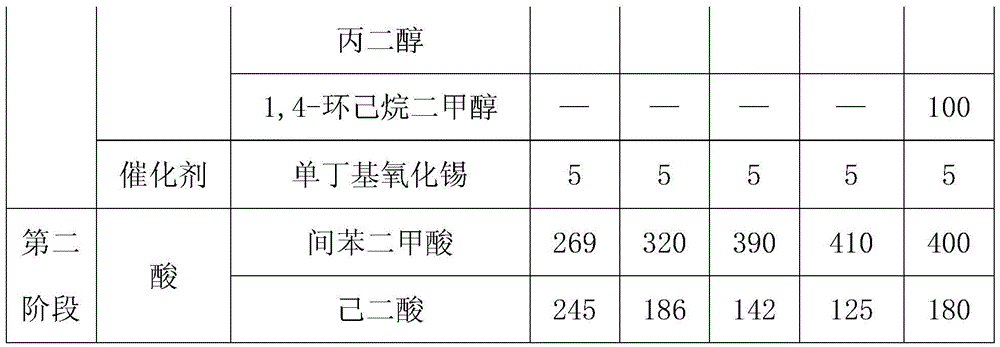

[0024] The second stage: Add acid and maintain the temperature at 230°C until the reactants are clear, and the acid value is 43mgKOH / g by sampling;

[0025] The third stage: under the condition of 225-235 ℃, the vacuum degree is -0.095--0.097MPa for 1.5-2h, and the acid value, viscosity and glass transition temperature are measured.

Embodiment 2

[0027] Preparation of frost-free polyester resin:

[0028] The first stage: Put the formula amount of alcohol into the reaction kettle, heat to 115°C, wait for the alcohol to completely melt, stir at a speed of 135r / min, then put the formula amount of acid and esterification catalyst, heat up to 175°C, / 30min heating rate to 246°C, maintaining an acid value of 9mgKOH / g;

[0029] The second stage: put in acid, maintain the temperature at 232°C, until the reactant is clear, and take a sample to measure the acid value to 44mgKOH / g;

[0030] The third stage: under the condition of 230°C, vacuumize for 1.8h with a vacuum degree of -0.096MPa, and measure the acid value, viscosity, and glass transition temperature.

Embodiment 3

[0032] Preparation of frost-free polyester resin:

[0033] The first stage: Put the formula amount of alcohol into the reaction kettle, heat to 120°C, wait for the alcohol to completely melt, stir at a speed of 140r / min, then put the formula amount of acid and esterification catalyst, heat up to 180°C, / 30min heating rate to 247°C, maintaining acid value 10mgKOH / g;

[0034] The second stage: add acid, maintain the temperature at 234 ° C, until the reactant is clear, take a sample and measure the acid value to 45 mgKOH / g;

[0035] The third stage: Under the condition of 235°C, vacuumize for 2 hours with a vacuum degree of -0.097MPa, and measure the acid value, viscosity, and glass transition temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com