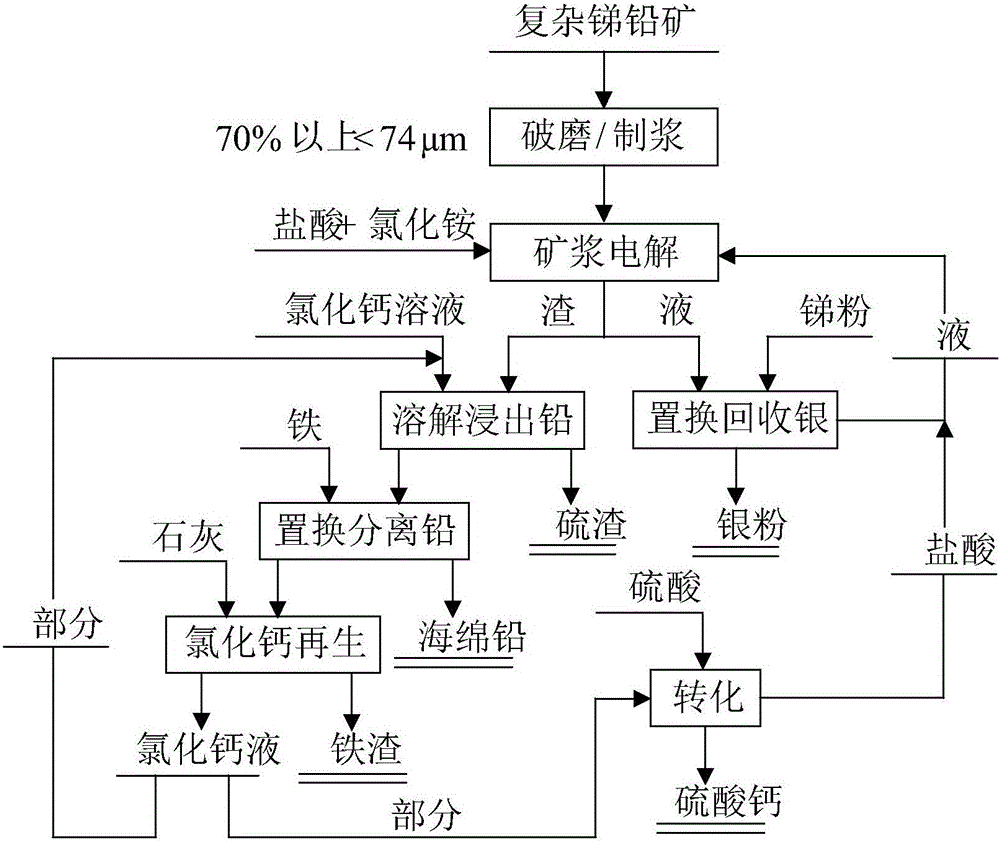

A method for recovering antimony and lead from antimony-lead complex sulfide ore

A sulfide ore and complex technology, applied in the field of lead and antimony recovery, can solve the problems of equipment corrosion, high power consumption and alkali consumption, high arsenic content in antimony white, and achieve the effect of clean and efficient comprehensive utilization of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The raw ore is crushed and wet-milled to obtain antimony-lead ore pulp with a particle size of less than 74 μm, accounting for 80%. The pulp is electrolytically separated in the ammonium chloride hydrochloride system to produce metal antimony, and the pulp is subjected to liquid-solid separation; 0.9 times the theoretical amount is added to the liquid. Antimony powder, the reaction temperature is 90°C, the reaction time is 1h, the replacement produces metallic silver, and the liquid is returned to the slurry electrolysis process; the slag is dissolved and leached with a calcium chloride solution with a concentration of 300g / L, the pH of the leaching process is 2.0, and the leaching temperature The temperature is 40°C, the time is 3 hours, and the liquid-solid ratio is 5:1. After the leaching is completed, the liquid-solid separation is carried out to produce sulfur residue, and the liquid enters the next step; add 1.0 times the theoretical amount of iron powder to the liq...

Embodiment 2

[0030] The raw ore is crushed and wet-milled to obtain antimony-lead ore pulp with a particle size of less than 74 μm, which accounts for 70%. The pulp is electrolytically separated in the ammonium hydrochloride system to produce metal antimony, and the pulp is subjected to liquid-solid separation; 1.1 times the theoretical amount is added to the liquid. Antimony powder, the reaction temperature is 20°C, the reaction time is 2h, the replacement produces metallic silver, and the liquid is returned to the slurry electrolysis process; the slag is dissolved and leached with a calcium chloride solution with a concentration of 400g / L, the pH of the leaching process is 3.0, and the leaching temperature The temperature is 90℃, the time is 1h, and the liquid-solid ratio is 3:1. After the leaching is completed, the liquid-solid separation is carried out to produce sulfur residue, and the liquid enters the next step; add 1.1 times the theoretical amount of iron powder to the liquid to repl...

Embodiment 3

[0032] After the raw ore is crushed and wet-milled, the antimony-lead ore pulp with a particle size of less than 74 μm, accounting for 90%, is electrolytically separated in the ammonium chloride hydrochloride system to produce metal antimony, and the liquid-solid separation of the pulp is carried out; 0.9 times the theoretical amount is added to the liquid. Antimony powder, the reaction temperature is 90°C, the reaction time is 0.5h, the replacement produces metallic silver, and the liquid is returned to the slurry electrolysis process; the slag is dissolved and leached with a calcium chloride solution with a concentration of 100g / L, and the pH of the leaching process is ~1.0. The temperature is 20°C, the time is 5 hours, and the liquid-solid ratio is 10:1. After the leaching is completed, the liquid-solid separation is carried out to produce sulfur residue, and the liquid enters the next step; add 0.9 times the theoretical amount of iron powder to the liquid to replace the prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com