A new type of towel press dryer

A technology for pressing dryers and towels, which is applied in textiles and papermaking, household utensils, washing devices, etc. It can solve the problems of waste of resources, power consumption, and low dehydration rate, and achieve the effect of easy operation and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

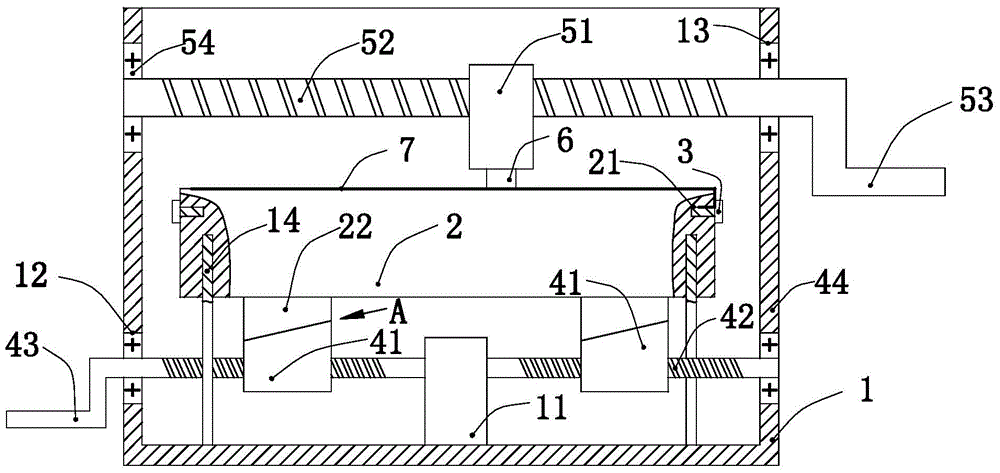

Method used

Image

Examples

Embodiment 2

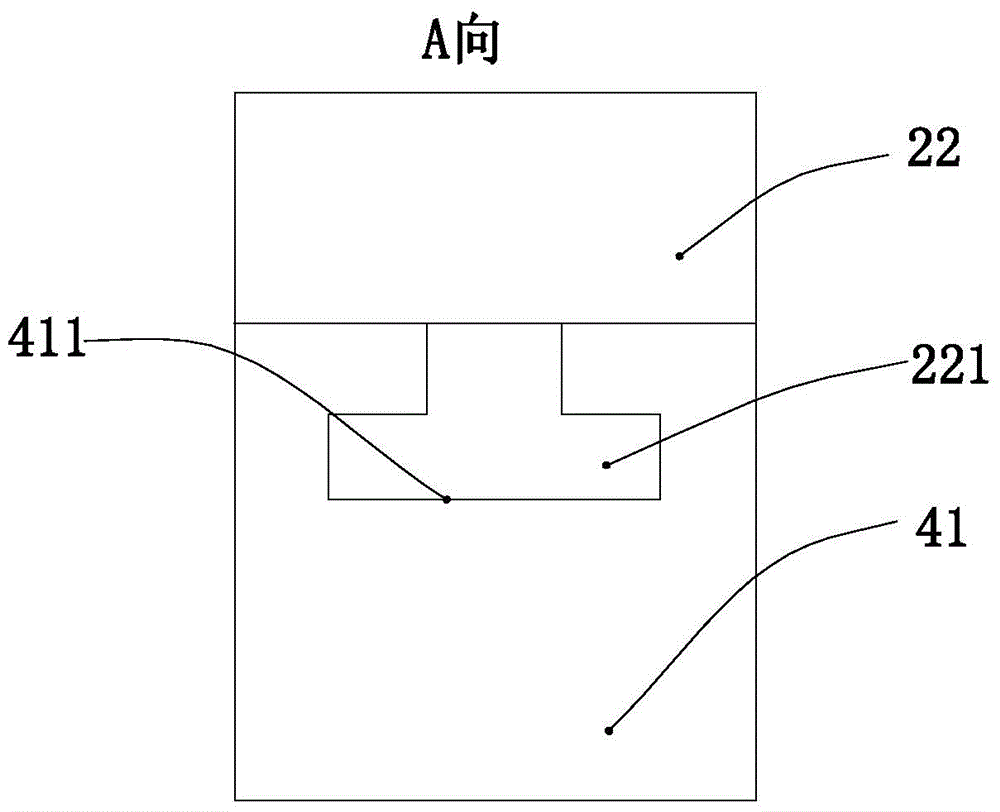

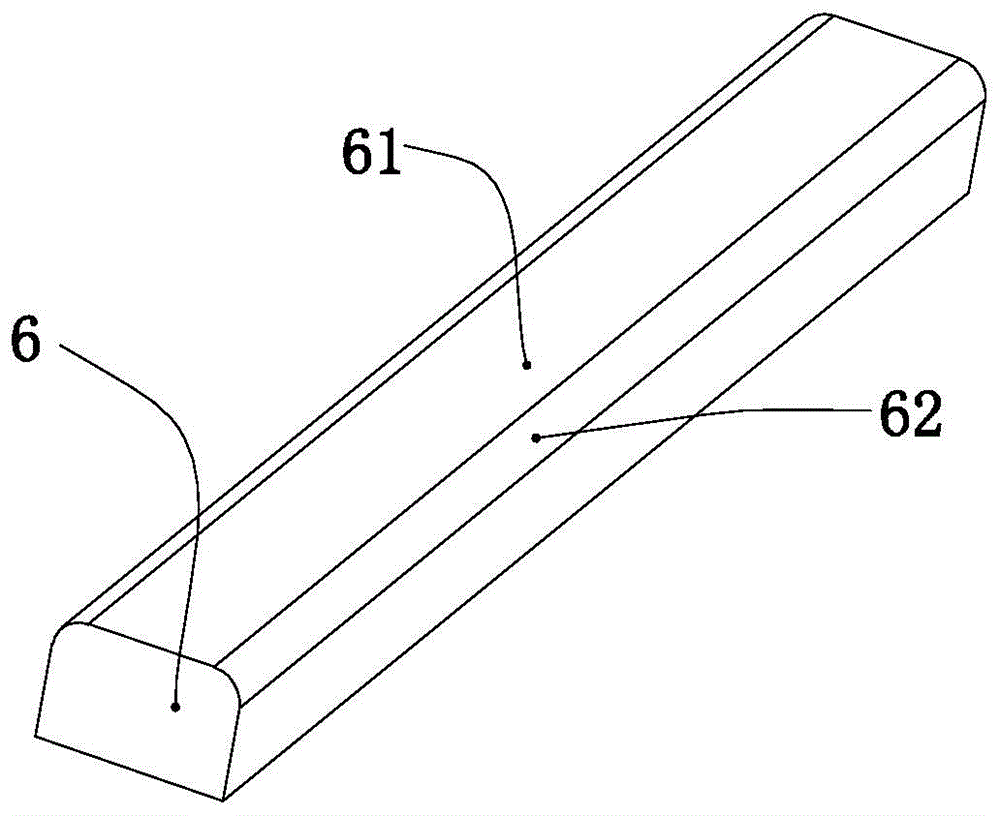

[0024] The difference between the second embodiment and the first embodiment lies in the sliding manner between the second lead screw nut and the slider. Specifically: as Figure 4 As shown, a second groove 412 is provided on the upper surface of the second lead screw nut, and the bottom surface of the second groove 412 is parallel to the upper surface of the second lead screw nut. Several balls 8 are placed in the second groove 412, and the balls can roll in the second groove. A long groove 222 is provided on the lower surface of the slider, and the long groove runs through the left and right sides of the slider; when installing, the bottom surface of the long groove is pressed on the ball, and when the first screw nut moves horizontally, it can pass The rolling of the ball realizes the relative sliding between the second lead screw nut and the slider, and simultaneously drives the slider and its plate to rise or fall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com