An anti-corrosion anchor rod for anchor support

A bolt and anchoring technology, applied in the installation of bolts, sheet pile walls, mining equipment, etc., can solve the problems of increased corrosion of steel bolts, easy cracks, expensive alloy steel, etc., and achieve advanced structural design Reasonable, long service life, good anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

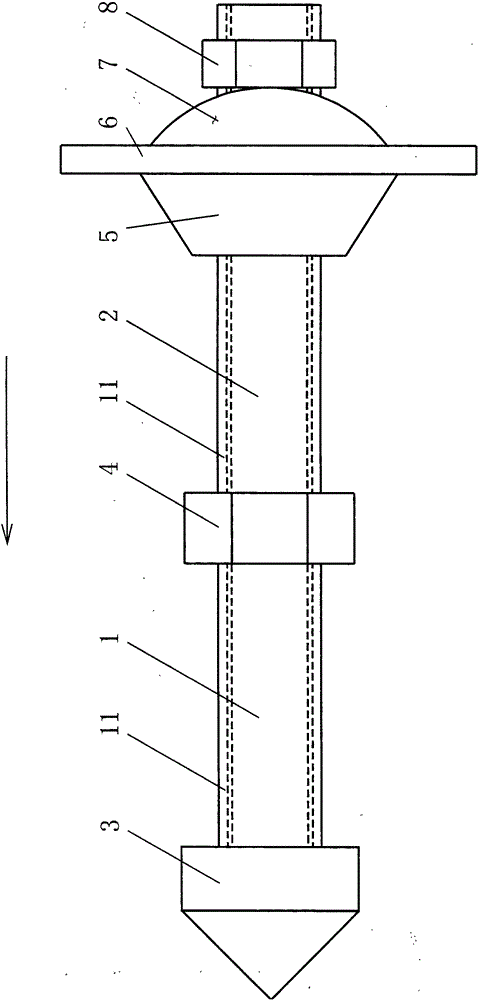

[0023] figure 1 As shown, it is the overall structural diagram of the anti-corrosion bolt. The position and connection relationship of each part must be correct and the installation should be firm.

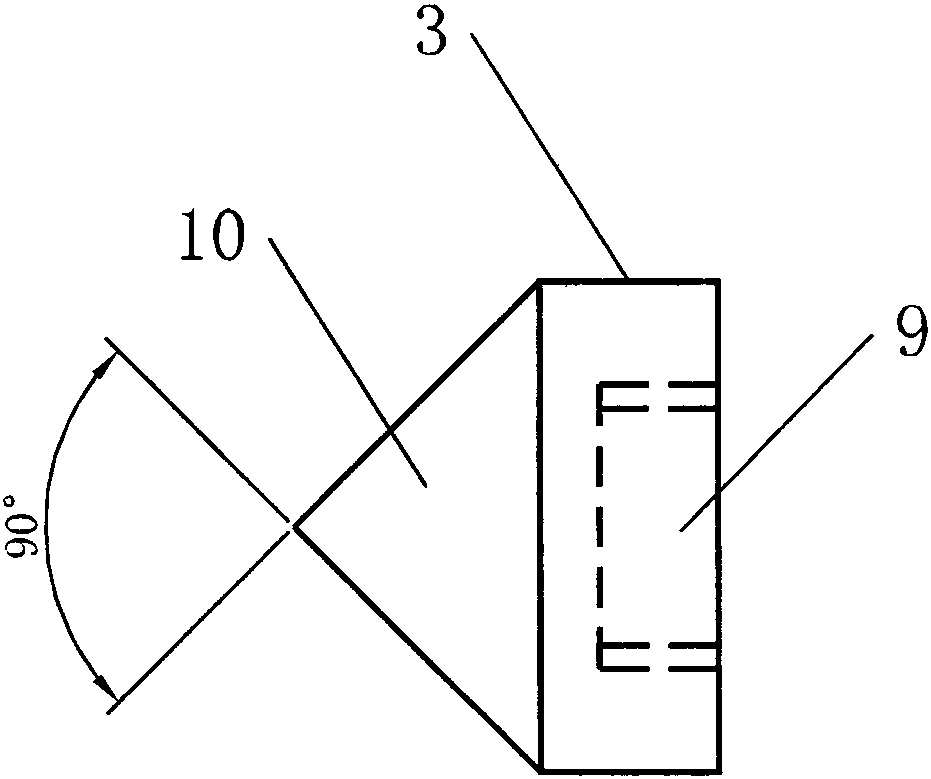

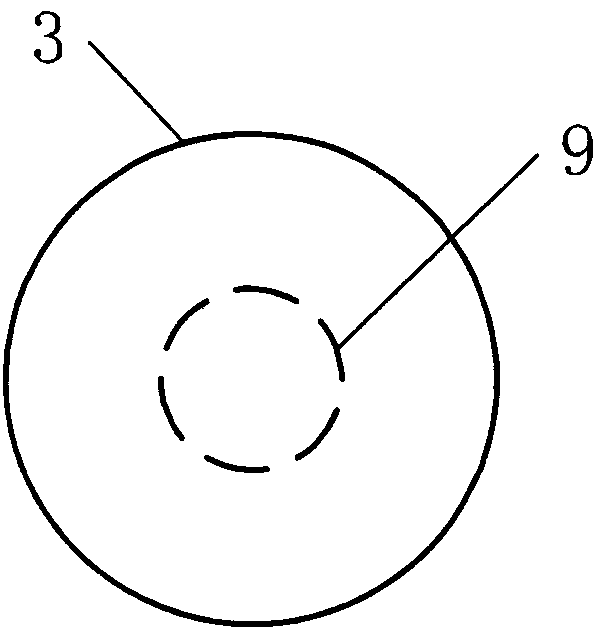

[0024] The first plastic-encapsulated threaded steel anchor 1 and the second plastic-enclosed threaded steel anchor 2 have the same structure, both of which are in the shape of a long axis, and the middle is screwed and fixedly connected by a plastic-enclosed hexagonal connecting sleeve 4; in front of the first plastic-enclosed threaded steel anchor 1 The part is a plastic anchor head 3, which is screwed and connected through the screw hole 9; the plastic-sealed grout stopper 5 is connected to the rear of the second plastic-sealed rebar anchor rod 2, and the plastic-sealed steel screw plug is connected to the rear of the plastic-sealed grout stopper 5. The backing plate 6 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com