A grouting filling method in the caving area of the broken roof

A technology for broken roof and caving area, which is applied in the direction of filling, earthwork drilling, safety devices, etc., can solve the problems of limited injection height, large height of caving zone in thick coal seams, and poor effect, so as to achieve small mining-filling contradictions, The effect of high filling rate and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

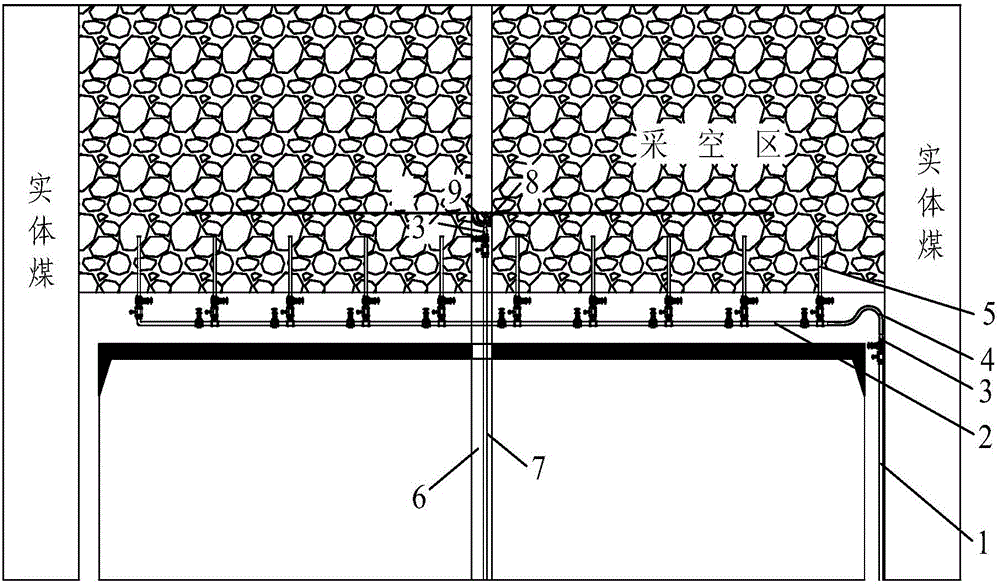

[0030] The invention discloses a grouting filling method for the caving area of a broken roof. In order to make the advantages and technical solutions of the invention clearer and clearer, the invention will be further clearly and completely described below in conjunction with specific implementation methods.

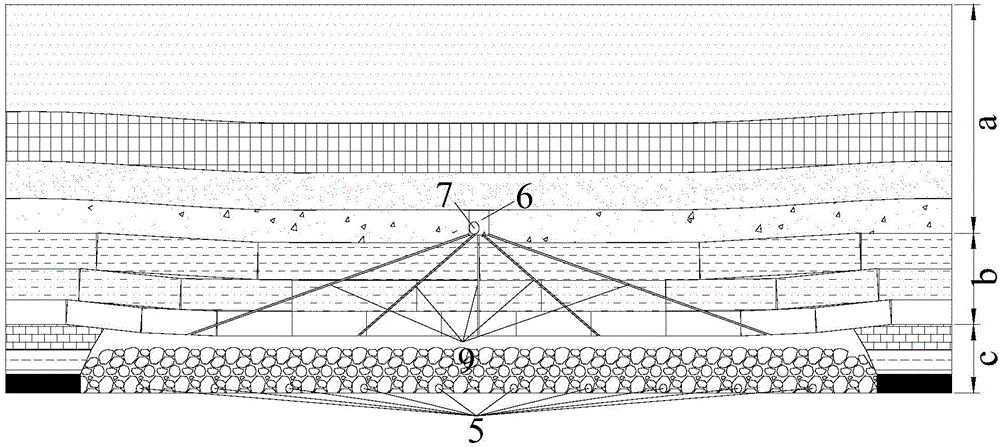

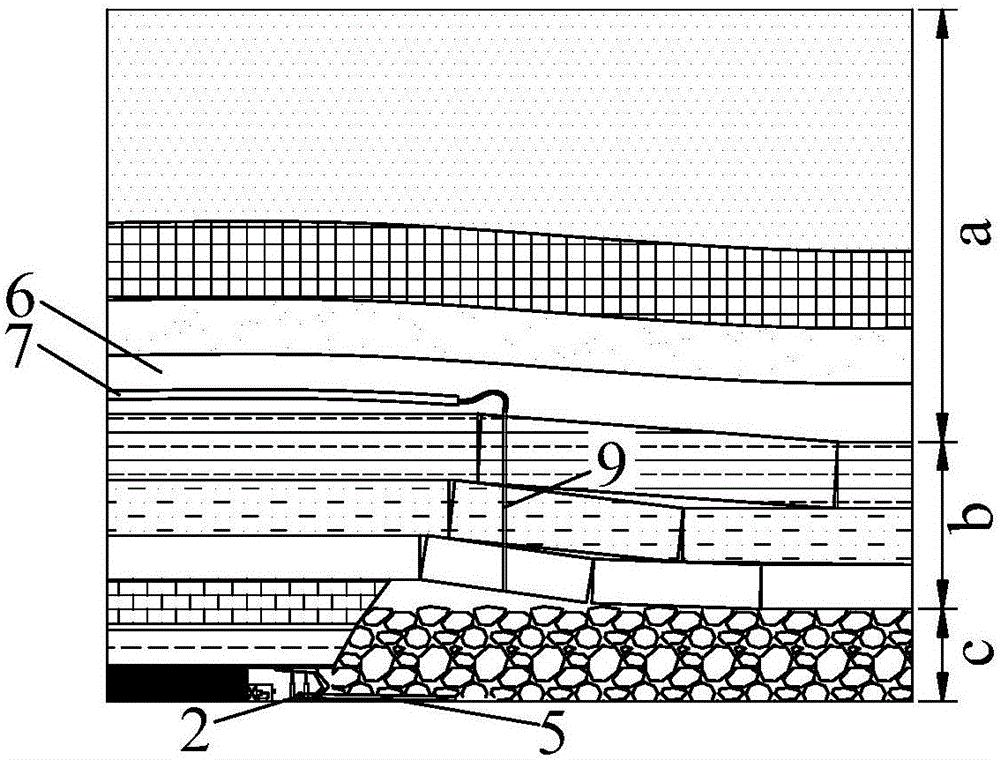

[0031] The curved subsidence zone a is the part of the rock formation that guides the top boundary of the water fracture zone to the surface;

[0032] The fissure zone b refers to the part of the rock stratum that is located above the caving zone and has water-conducting fissures connected to the goaf, but the continuity is not damaged;

[0033] The caving zone c refers to the part of the rock formation that breaks away from the rock matrix, loses continuity, and is in the form of irregular rock blocks or layered rock blocks caving to the goaf.

[0034] combine Figure 1 to Figure 3 As shown, in the present invention, a grouting filling method for a broken roof cavin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com