Hydraulic piston pump lifting system

A hydraulic piston and hydraulic technology, applied in the field of pumping systems, can solve problems such as falling wells, short-circuiting of downhole liquid channels, grinding and breaking production strings, etc., and achieve the effect of improving ultimate recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

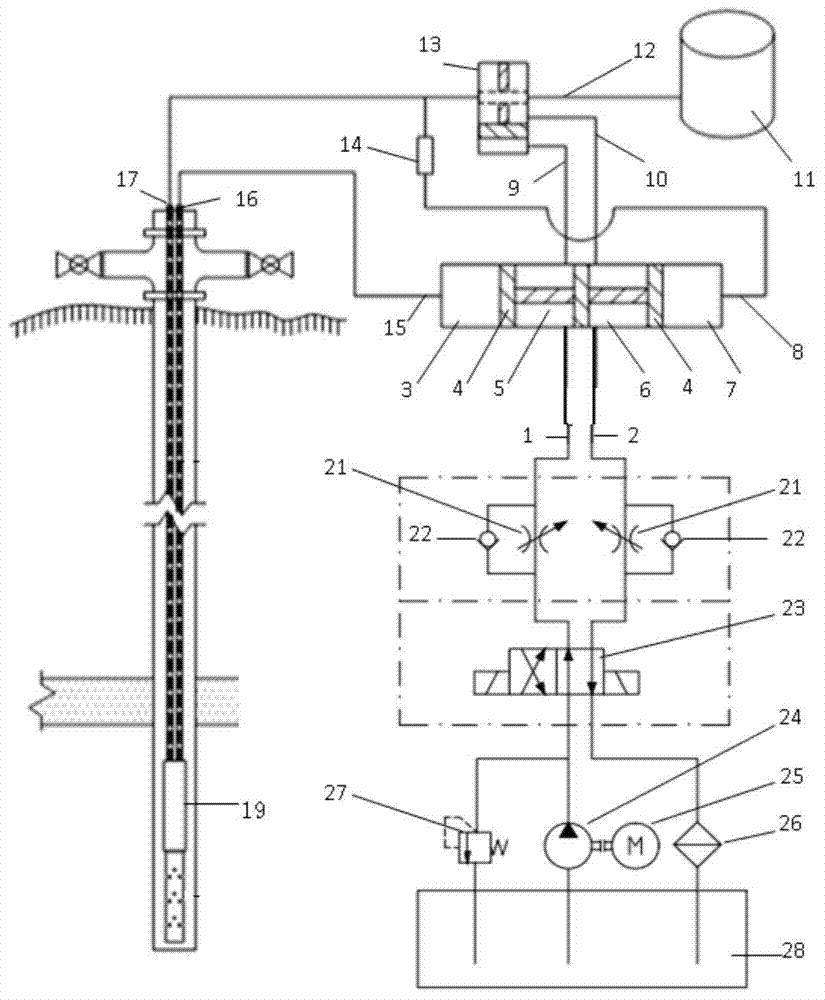

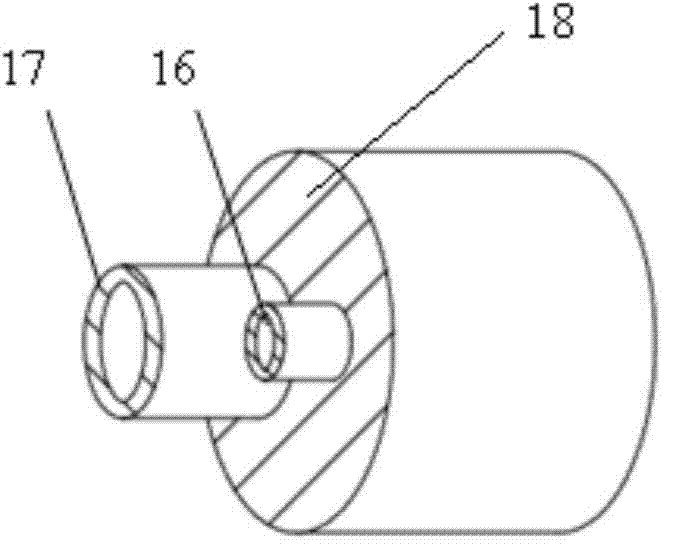

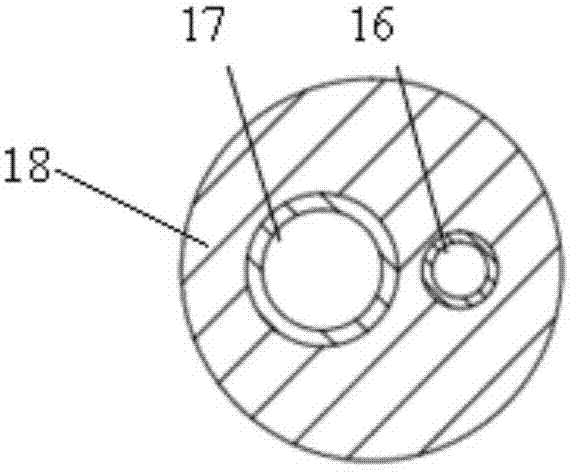

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the hydraulic plunger pump system of the present invention mainly includes a surface hydraulic power conversion control part, a flexible downhole integrated pipeline part and a downhole hydraulic plunger pump. The main function of the ground hydraulic power conversion control part is to convert the ground high-pressure hydraulic oil power into high-pressure liquid (it can be high-pressure oil, if it is an oil well, the liquid is a mixture of oil and water, if it is a gas well, the liquid is water) medium power output, It provides a hydraulic power source for the reciprocating movement of the downhole hydraulic plunger pump and discharges the downhole produced fluid. The downhole integrated pipeline is a channel for transmitting hydraulic power to the downhole hydraulic plunger pump and a channel for lifting the downhole produced flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com