Gas leakage alarm system of LNG heavy truck

A technology of gas leakage and alarm system, which can solve the problem of insufficient accuracy of combustible gas alarm system, difficulty in finding leakage, and low cost by detecting the appearance of fluid at the leakage point, the arrangement combined with the fuel supply of the internal combustion engine, and the power device. High-level problems, to reduce the probability of false alarms or no alarms, maintain driving safety, and reduce the number of sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

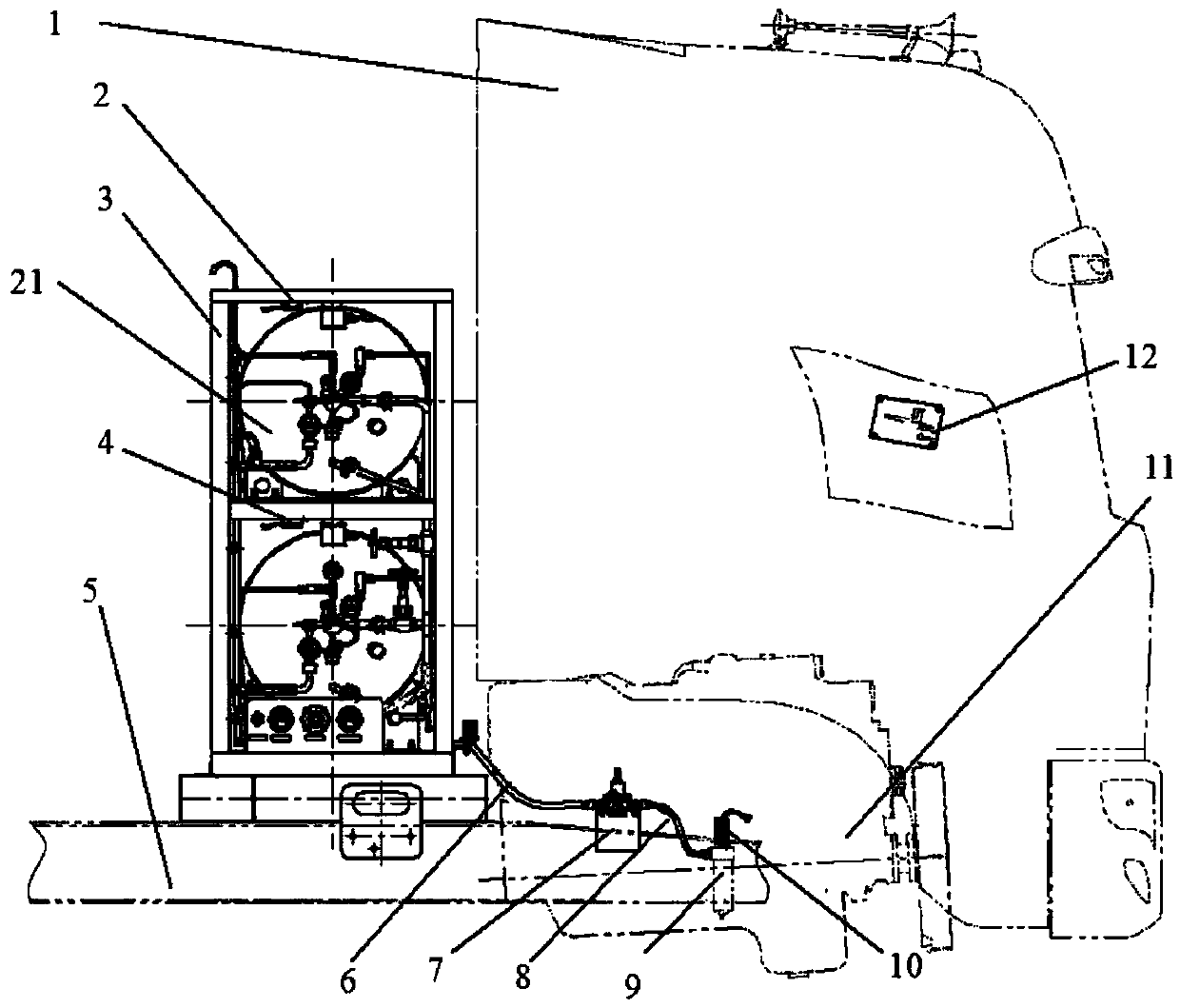

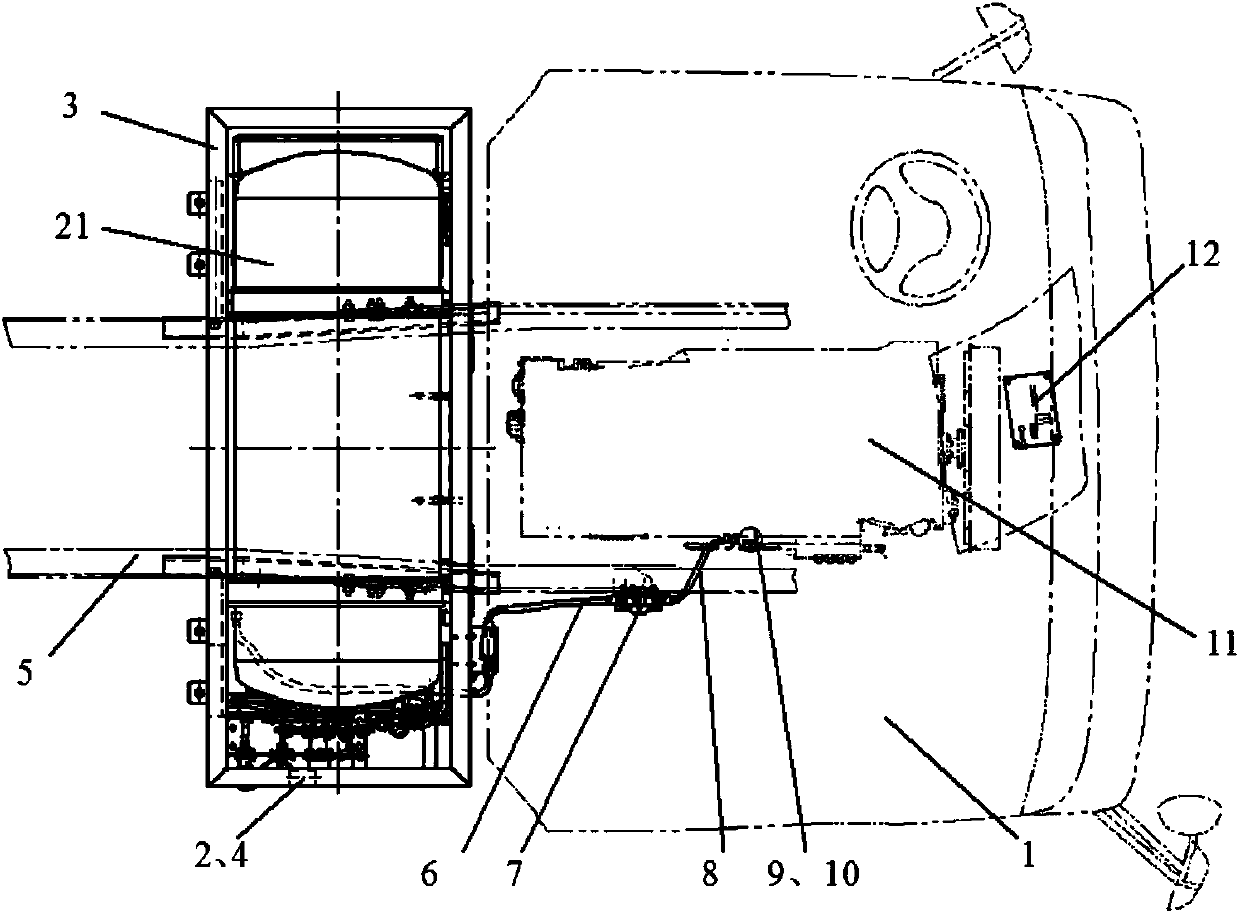

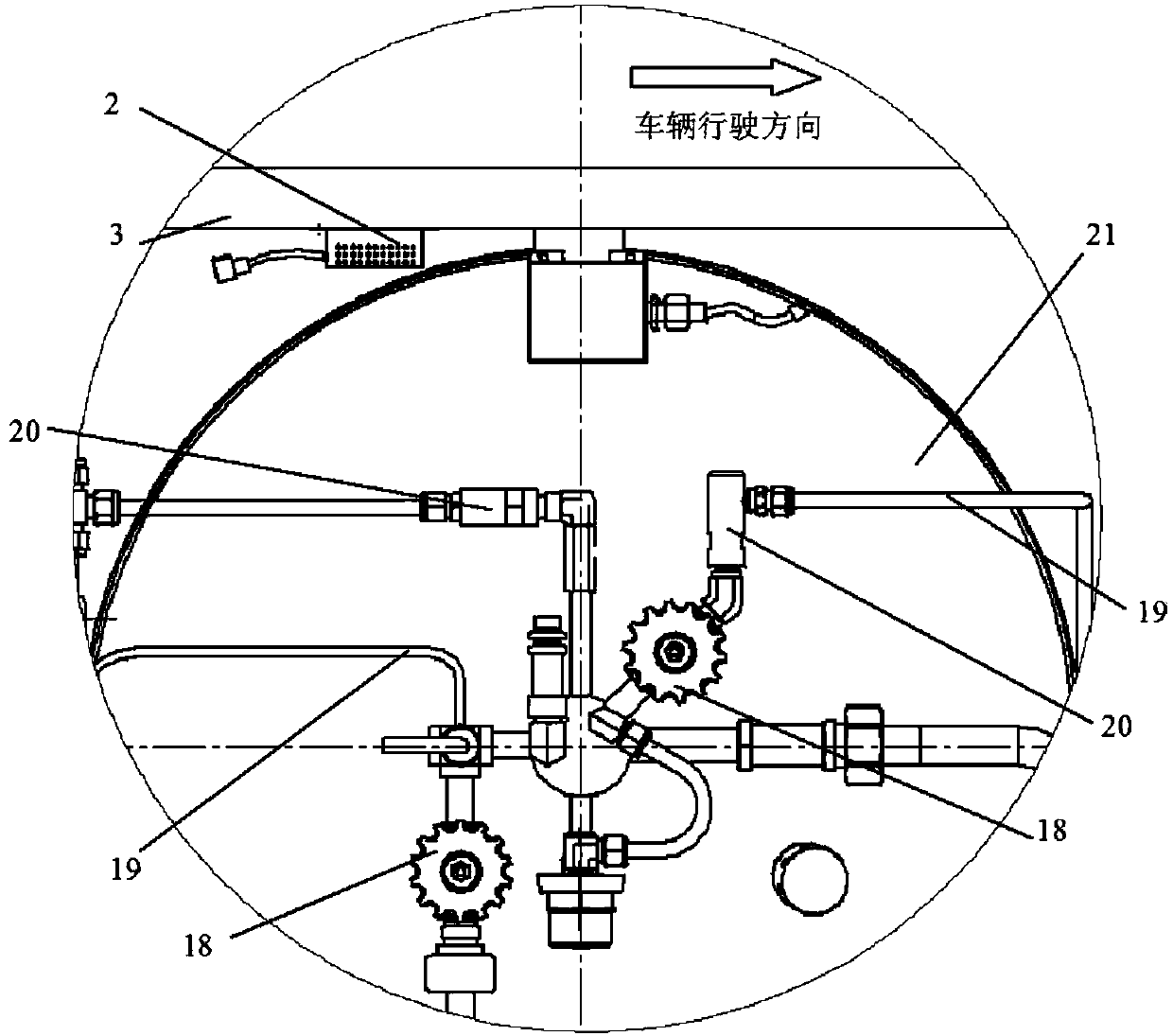

[0028] combine Figure 4 , Figure 5 , visible with Figure 1 to Figure 3 What is different from the prior art shown in is that in the vehicle gas leakage alarm system of the embodiment of the present invention, the fixed cover 13 and the guide cover 14 are added. The fixing cover 13 can be formed by stamping metal material or injection molding plastic material, and has certain rigidity. Preferably, the wind deflector 14 is made of a flame retardant material such as polyvinyl chloride, and has a certain degree of flexibility, that is, the wind deflector 14 is deformable to a certain extent. The lower end of the shroud 14 is a large opening and the upper end is a small opening, wherein the small opening communicates with the fixed cover 13 and is fastened by devices such as clamps 15 or screws. Depend on Figure 4 It can be clearly seen that although the arrangement of the valve 18 and the pipeline 19 attached to the gas bottle 21 is very complicated, and multiple joints 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com