Compressing model sample disc for dynamic thermal mechanical analyzer

A dynamic thermomechanical and sample disk technology, applied in the investigation stage/state change, etc., can solve the problems of small sample contact area, large sample cell diameter, large measurement error, etc., and achieve the effect of simple structure, low cost, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

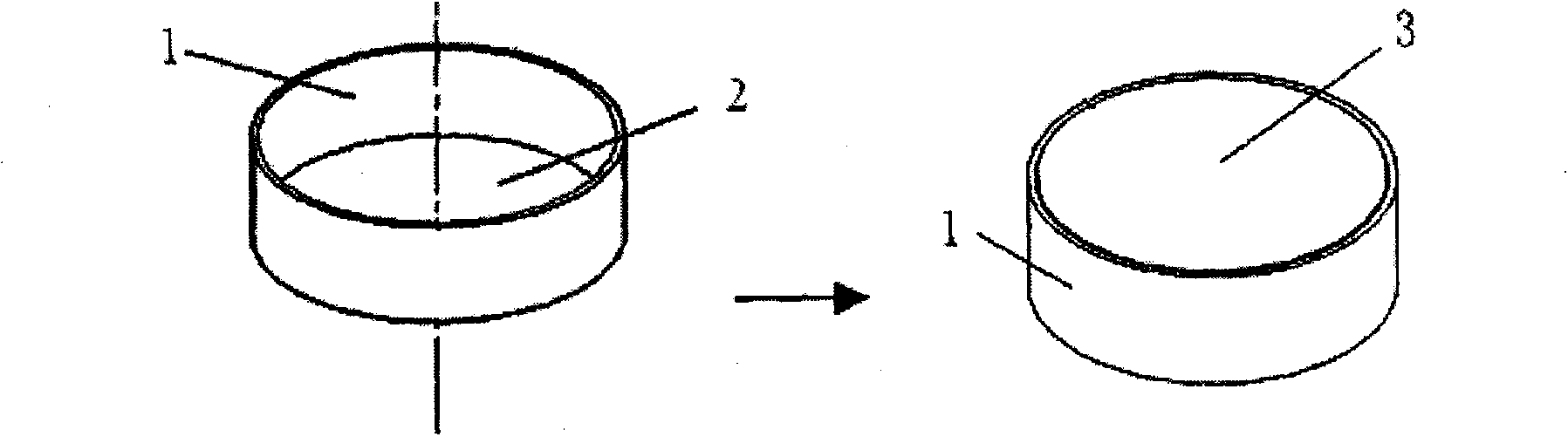

[0015] Design and manufacture the sample tray, the inner diameter of the disc is 5.0mm, the thickness is 0.5mm, and the height of the inner wall is 3.0mm; the supporting design of the tray cover is 4.5mm in diameter, and the thickness is 0.2mm; the sample tray and the cover are made of brass material, The allowable tolerance is ±0.05mm.

Embodiment 2

[0017] Design and manufacture the sample tray, the inner diameter of the disc is 8.0mm, the thickness is 1.5mm, and the height of the inner wall is 5.0mm; the supporting design of the tray cover is 7.5mm in diameter, and the thickness is 1.0mm; the sample tray and the cover are made of brass material, The allowable tolerance is ±0.05mm.

Embodiment 3

[0019] Design and manufacture the sample tray, the inner diameter of the disc is 6.0mm, the thickness is 1.0mm, and the height of the inner wall is 4.0mm; the supporting design of the tray cover is 5.5mm in diameter, and the thickness is 0.5mm; the sample tray and the cover are made of brass material, The allowable tolerance is ±0.05mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap