Correction and test system and method for miss distance of large target surface

A test system and miss target technology, which is applied in radio wave measurement systems, measurement devices, and devices that measure the time required to move a certain distance, etc., can solve the difficulty of calibration of the test system, the inability to image the specific location of the projectile, and the difficulty in measuring the geometry. angle value etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

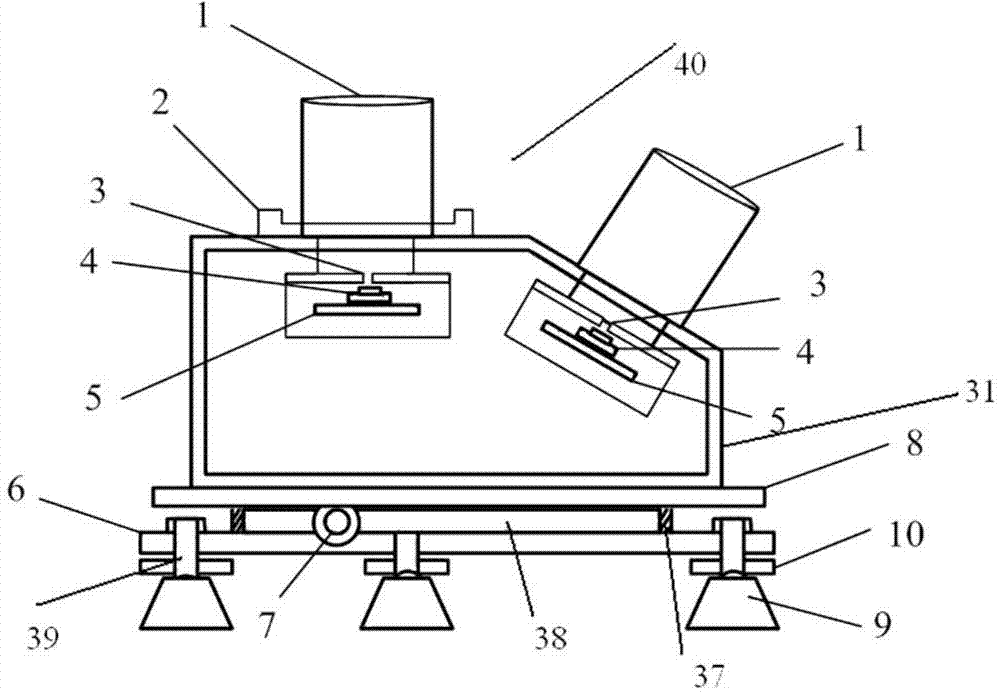

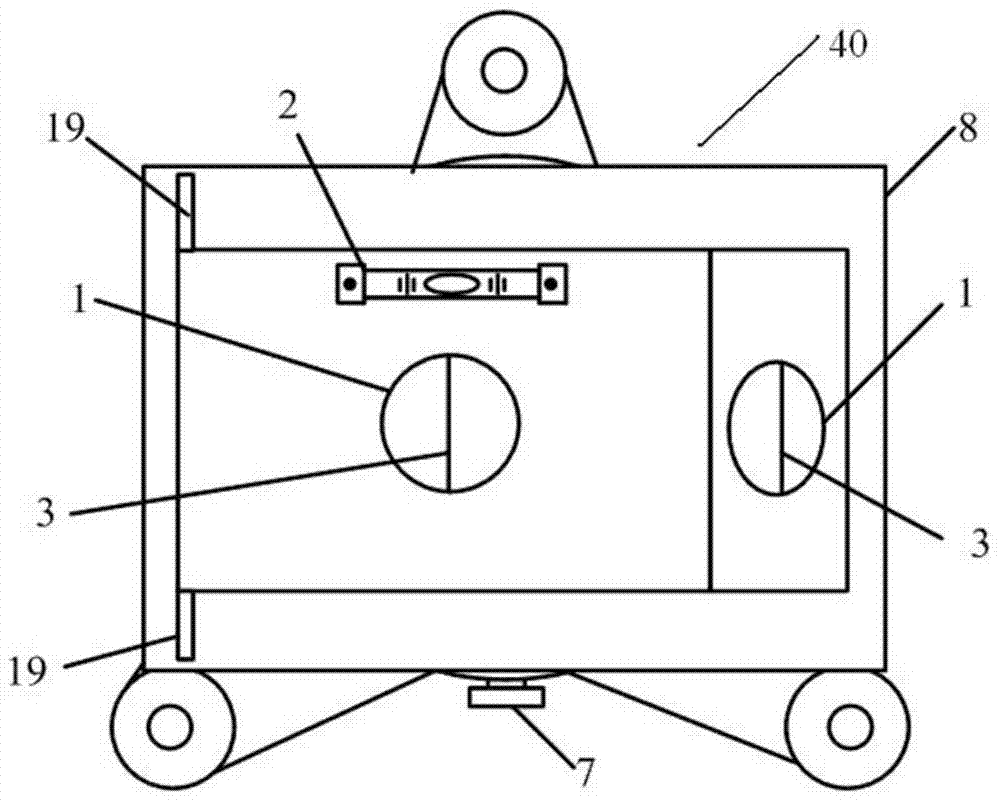

[0041] In the following, the large target area miss correction test system and the side view method of the present invention will be described in detail with reference to the accompanying drawings.

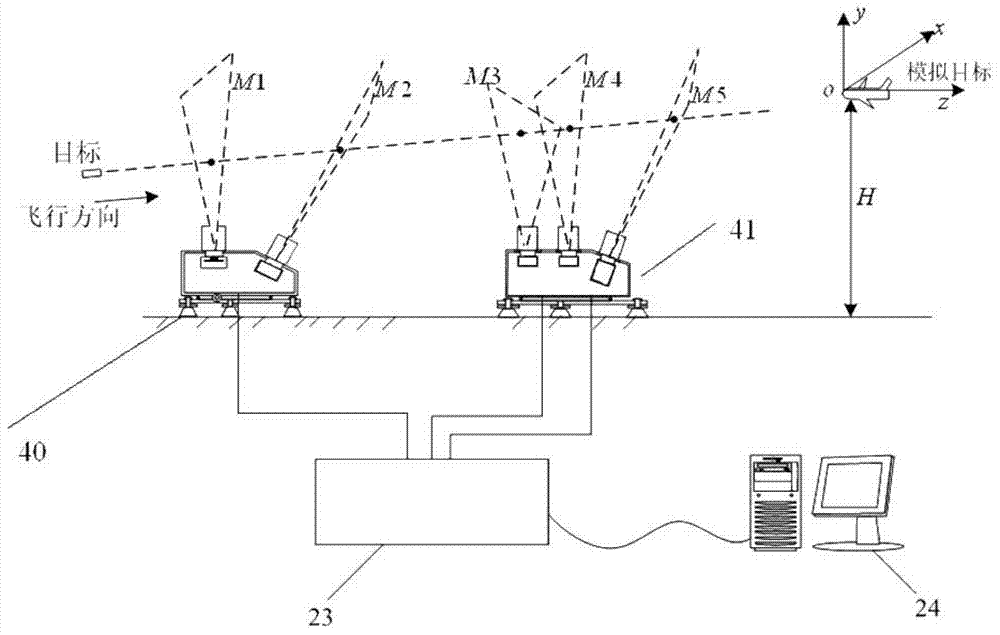

[0042] Such as figure 1 As shown, a large target surface miss-target correction test system is shown, which includes a first photoelectric detection target 40, a second photoelectric detection target 41, a timing and image acquisition instrument 23, wherein the first photoelectric detection target 40 and the second photoelectric detection target body 41 are adjacently arranged in the test section of the target track along the firing direction of the gun, and these two photoelectric detection target bodies are all connected with timing and image acquisition instrument 23, timing and image acquisition instrument 23 and A computer 24 is connected. Among them, the first photoelectric detection target body 40 and the second photoelectric detection target body 41 transmit the detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com