Lamp aging test line

An aging test and lighting technology, applied in lighting test, vibration test, machine/structural component test, etc., can solve problems such as low efficiency, insufficient safety, waste of manpower, etc., and achieve the effect of safe and reliable operation and high test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

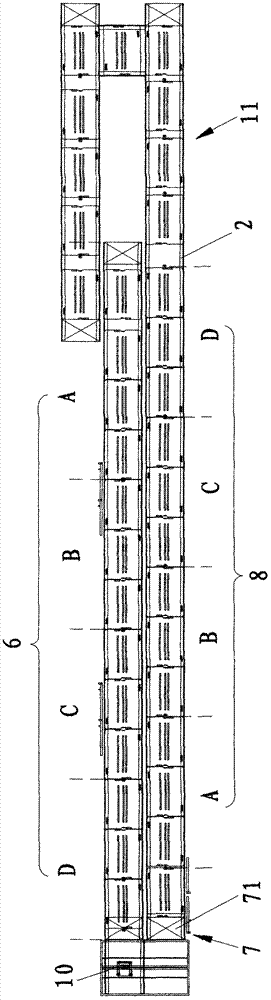

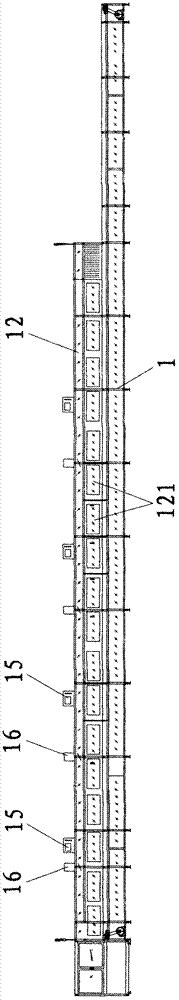

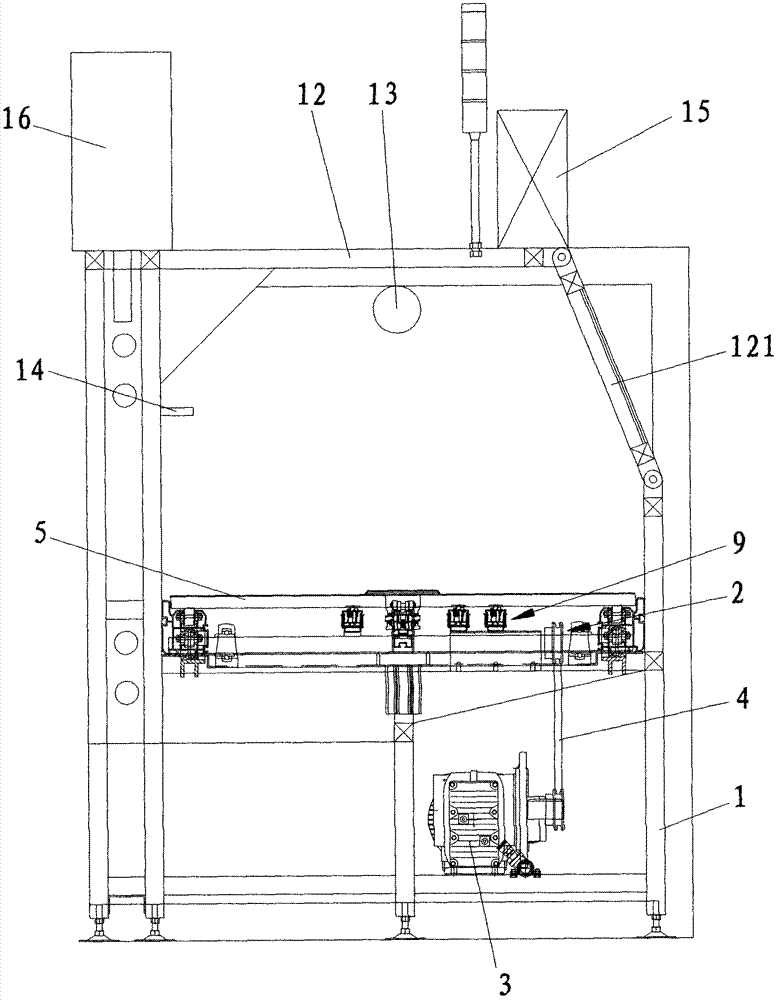

[0023] The present invention will be further described below in conjunction with the accompanying drawings, such as Figures 1 to 7 As shown, the lamp aging test line provided by the present invention includes a frame 1, and the frame 1 is provided with a conveying track 2 for conveying lamps, a driving motor 3, and a transmission mechanism 4, and the output end of the driving motor 3 is driven by the transmission mechanism 4. The conveying track 2 is connected, and the conveying track 2 forms a ring-shaped circulating conveying structure. The conveying track 2 can be a conveying chain, a conveying belt or a conveying roller. In this embodiment, the conveying track 2 is formed by arranging several conveying rollers, and the conveying roller is driven to rotate by the driving motor 3 and the transmission mechanism 4 to drive the tooling plate. 5 Move.

[0024] The conveying track 2 is provided with a tooling plate 5 that is pushed by the conveying track 2 to move along the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com