A fiber Bragg grating space magnetic field intensity sensor based on giant magnetostrictive material and its application method

A technology of giant magnetostriction and magnetic field strength, which is used in the use of magneto-optical equipment for magnetic field measurement, magnetic field size/direction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

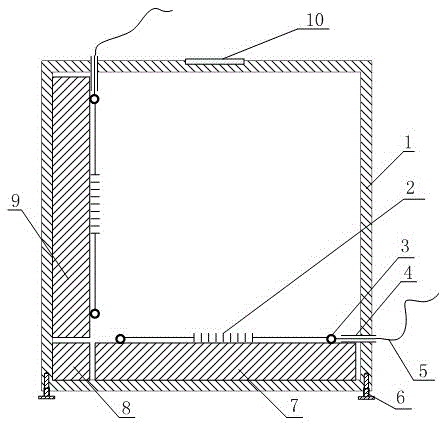

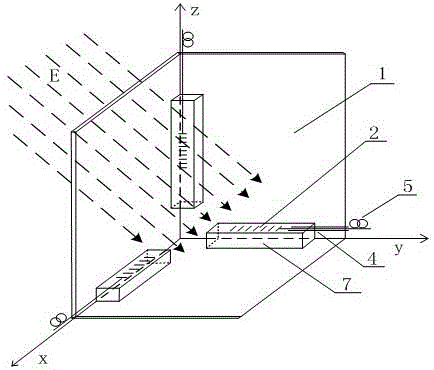

[0047] Embodiment 1: as Figure 1-2 As shown, a fiber Bragg grating spatial magnetic field intensity sensor based on giant magnetostrictive materials, including a polytetrafluoroethylene shell 1, a fiber Bragg grating 2, a fixed bump 3 of an optical fiber, a polytetrafluoroethylene sleeve 4, and an external optical fiber 5 , giant magnetostrictive material Ⅰ7, giant magnetostrictive material Ⅱ8, and giant magnetostrictive material Ⅲ9; among them, giant magnetostrictive material Ⅰ7, giant magnetostrictive material Ⅱ8, and giant magnetostrictive material Ⅲ9 are respectively located in the PTFE shell There are two optical fiber fixing bumps 3 on the three orthogonal edges in 1 and the two ends of the surface of the three giant magnetostrictive materials, and the giant magnetostrictive material II 8 is connected to the polytetrafluoroethylene shell 1 with elastic epoxy glue , the middle of the two optical fiber fixing bumps 3 is the fiber Bragg grating 2, the fiber Bragg grating 2...

Embodiment 2

[0053] Embodiment 2: as Figure 1-2 As shown, a fiber Bragg grating spatial magnetic field intensity sensor based on giant magnetostrictive materials, including a polytetrafluoroethylene shell 1, a fiber Bragg grating 2, a fixed bump 3 of an optical fiber, a polytetrafluoroethylene sleeve 4, and an external optical fiber 5 , giant magnetostrictive material Ⅰ7, giant magnetostrictive material Ⅱ8, and giant magnetostrictive material Ⅲ9; among them, giant magnetostrictive material Ⅰ7, giant magnetostrictive material Ⅱ8, and giant magnetostrictive material Ⅲ9 are respectively located in the PTFE shell There are two optical fiber fixing bumps 3 on the three orthogonal edges in 1 and the two ends of the surface of the three giant magnetostrictive materials, and the giant magnetostrictive material II 8 is connected to the polytetrafluoroethylene shell 1 with elastic epoxy glue , the middle of the two optical fiber fixing bumps 3 is the fiber Bragg grating 2, the fiber Bragg grating 2...

Embodiment 3

[0058] Embodiment 3: as Figure 1-2 As shown, a fiber Bragg grating spatial magnetic field intensity sensor based on giant magnetostrictive materials, including a polytetrafluoroethylene shell 1, a fiber Bragg grating 2, a fixed bump 3 of an optical fiber, a polytetrafluoroethylene sleeve 4, and an external optical fiber 5 , giant magnetostrictive material Ⅰ7, giant magnetostrictive material Ⅱ8, and giant magnetostrictive material Ⅲ9; among them, giant magnetostrictive material Ⅰ7, giant magnetostrictive material Ⅱ8, and giant magnetostrictive material Ⅲ9 are respectively located in the PTFE shell There are two optical fiber fixing bumps 3 on the three orthogonal edges in 1 and the two ends of the surface of the three giant magnetostrictive materials, and the giant magnetostrictive material II 8 is connected to the polytetrafluoroethylene shell 1 with elastic epoxy glue , the middle of the two optical fiber fixing bumps 3 is the fiber Bragg grating 2, the fiber Bragg grating 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap