Semiconductor temperature difference matrix power generation device

A power generation device and thermoelectric power generation technology, applied in the directions of generators/motors, electrical components, etc., can solve the problem of high cost of thermoelectric semiconductors, and achieve the effects of good thermal conductivity, high power generation efficiency, and high solution costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

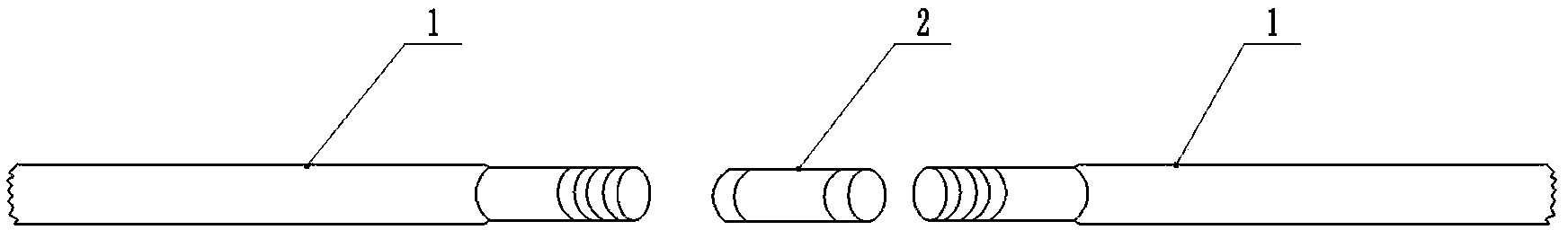

[0019] refer to figure 1 , a kind of semiconductor temperature difference matrix power generation device of the present invention, by semiconductor thermoelectric power generation block 2 and be respectively arranged on this power generation block 2 two ends positive temperature copper block 1 and negative temperature copper block 3 by screw connection, semiconductor thermoelectric power generation block 2 and positive temperature copper block Block 1 and negative temperature copper block 3 are respectively fixed and closed by fixing silica gel.

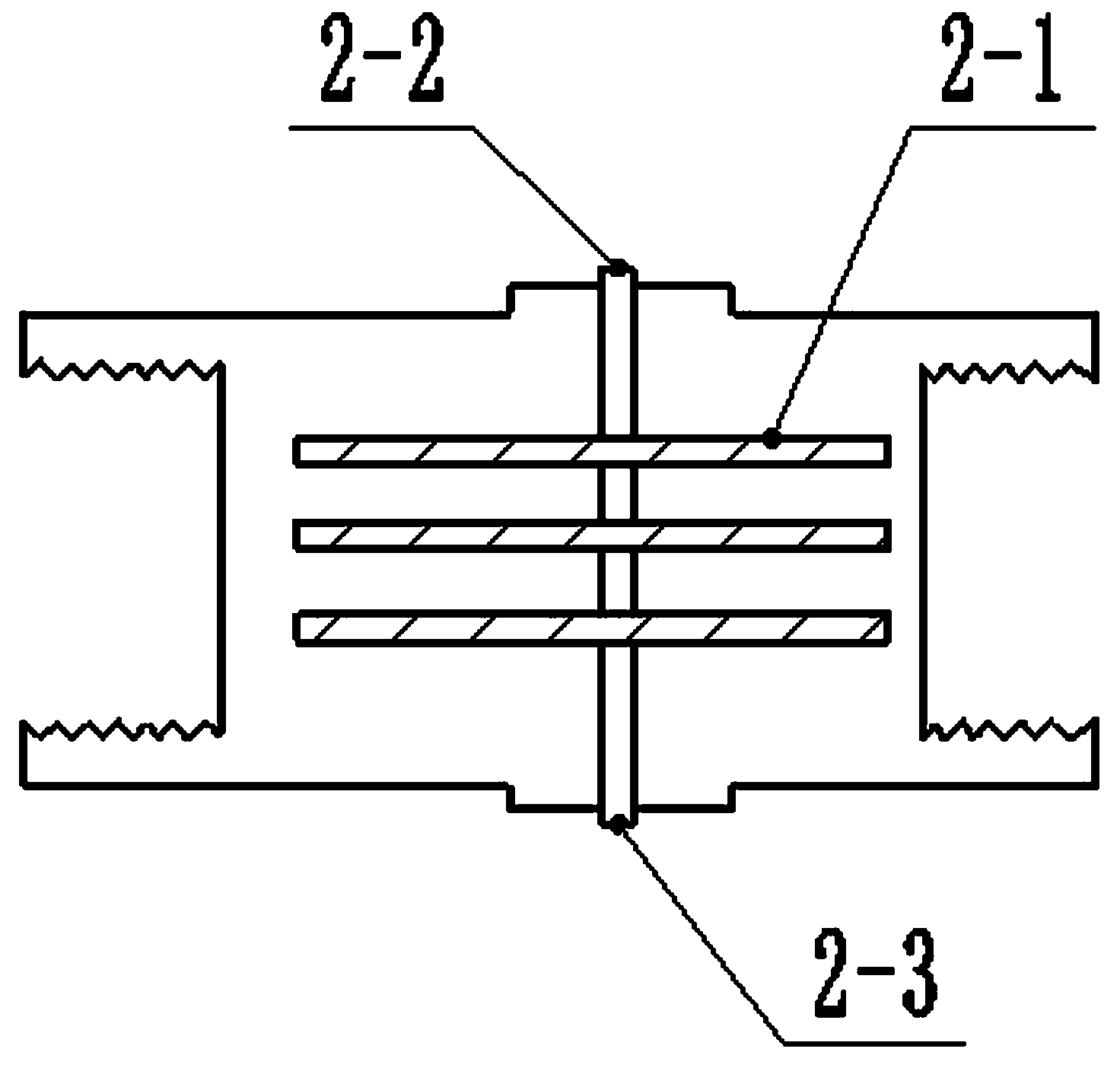

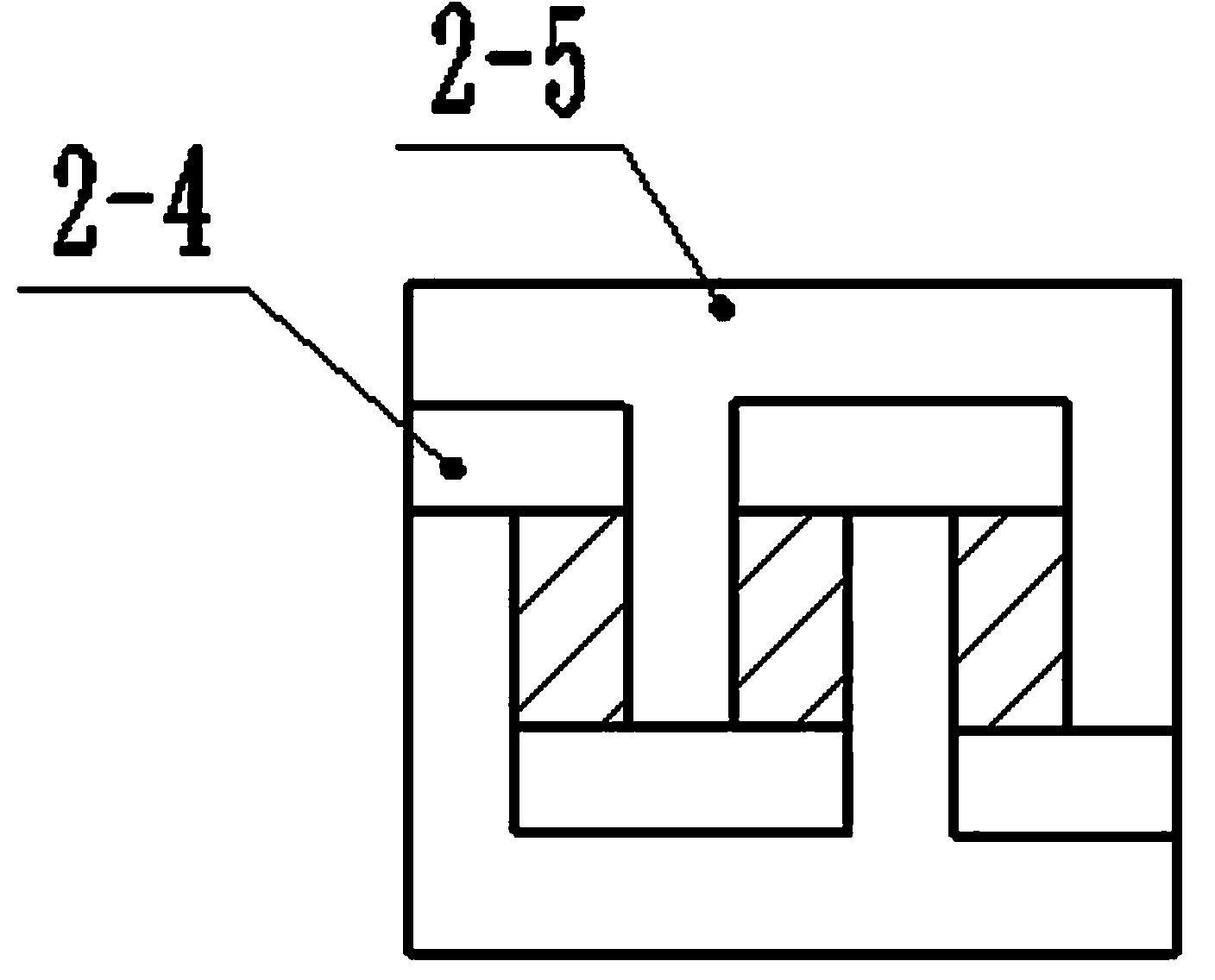

[0020] refer to Figure 2-3 The semiconductor thermoelectric power generation block 2 includes a semiconductor power generation block 2-1, a positive terminal 2-2 and a negative terminal 2-3 which are arranged in the semiconductor power generation block 2-1 and respectively run through the upper and lower ends of the semiconductor power generation block 2-1. and the metal conductor 2-5 coated outside the semiconductor power generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com