Heat conduction graphite patch for microelectronic device

A technology of microelectronic devices and thermally conductive graphite, which is applied in the direction of electronic equipment, electrical components, electrical equipment structural parts, etc. Instable performance and other problems, to avoid volume shrinkage, improve thermal conductivity, improve compactness and crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

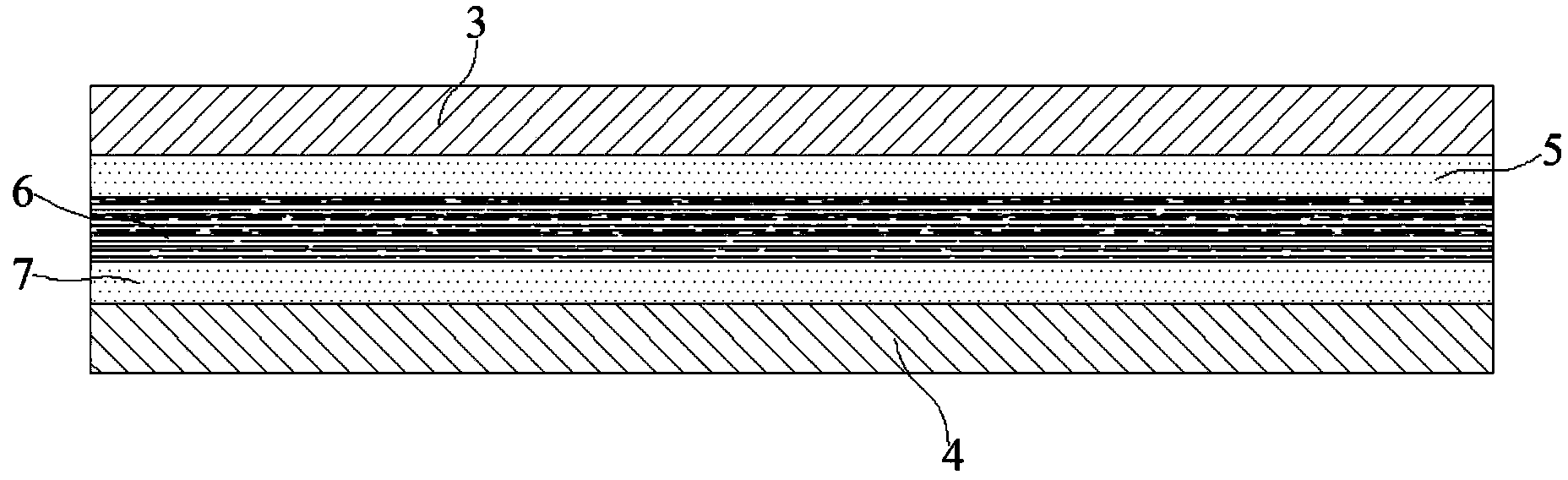

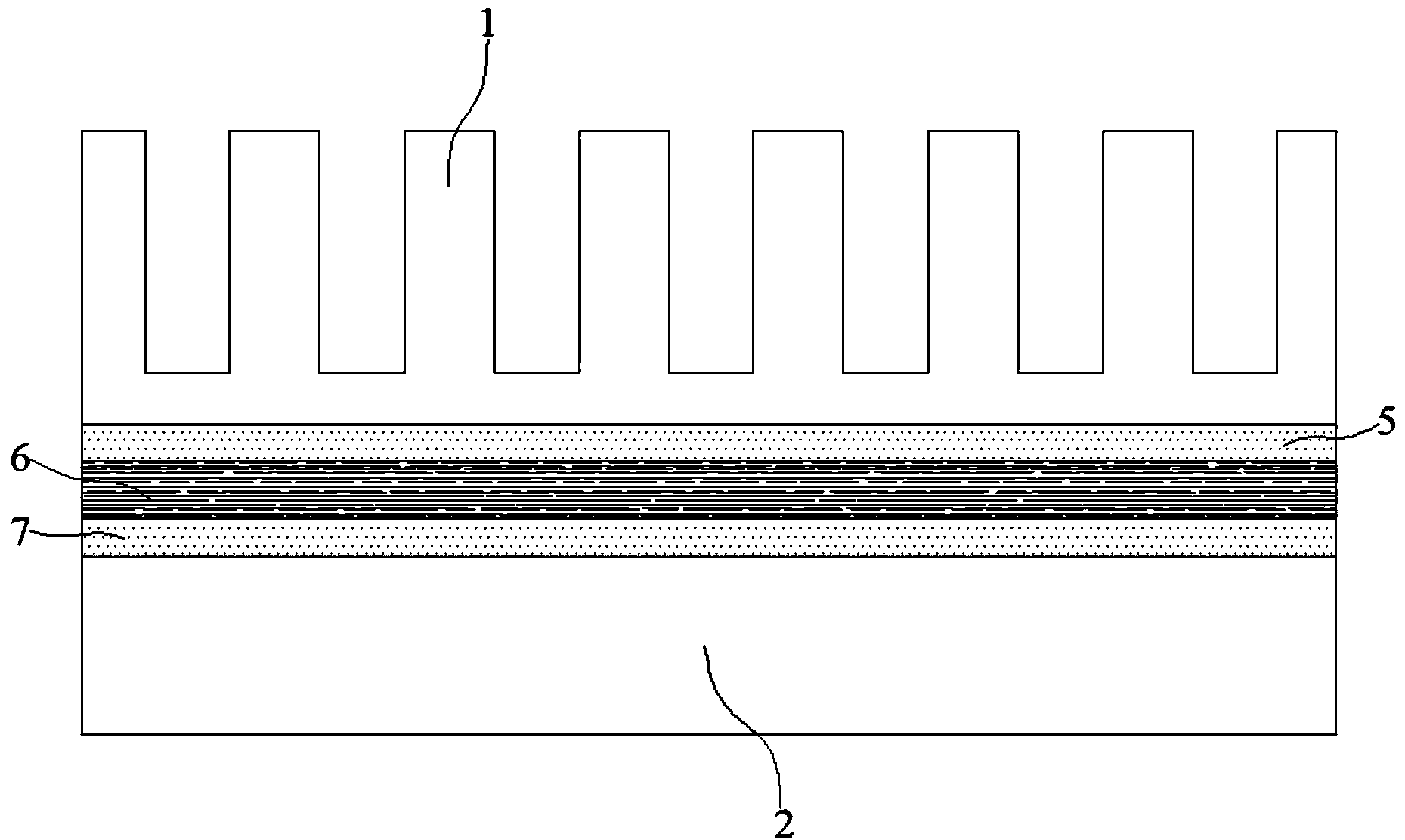

[0042] Embodiment: a heat-conducting graphite patch for microelectronic devices, the heat-dissipating double-sided film is attached between the heat-dissipating element 1 and the heating component 2, and the heat-dissipating double-sided film includes a light-peelable PET film 3 and a heavy-duty Peel-off PET film 4, between the light peel-off PET film 3 and the heavy peel-off PET film 4, a first heat-conducting adhesive layer 5, a graphite layer 6 and a second heat-conducting adhesive layer 7 are sequentially arranged; the graphite layer 6 Obtained by the following process method, which process method comprises the following steps:

[0043] Step 1. Raise the polyimide film from room temperature to 250°C at a speed of 4~6°C / min, keep it for 0.9~1.1 hours, then raise it to 400°C at a speed of 2.5~3.5°C / min, keep it for 1 hour and then lower it. to room temperature;

[0044] Step 2, on the upper and lower surfaces of the polyimide film through step 1, a layer of graphite modifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com