Tapping machine automatic feeding system

An automatic feeding and tapping machine technology, which is applied in the direction of metal processing machinery parts, measuring/indicating equipment, tangential feeding devices, etc., can solve the problem that it is difficult to guarantee the stability of pipe fittings and the consistency of their state, which affects working stability and Reliability, work efficiency is difficult to continue to improve and other problems, to achieve the effect of overcoming unstable work, good consistency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

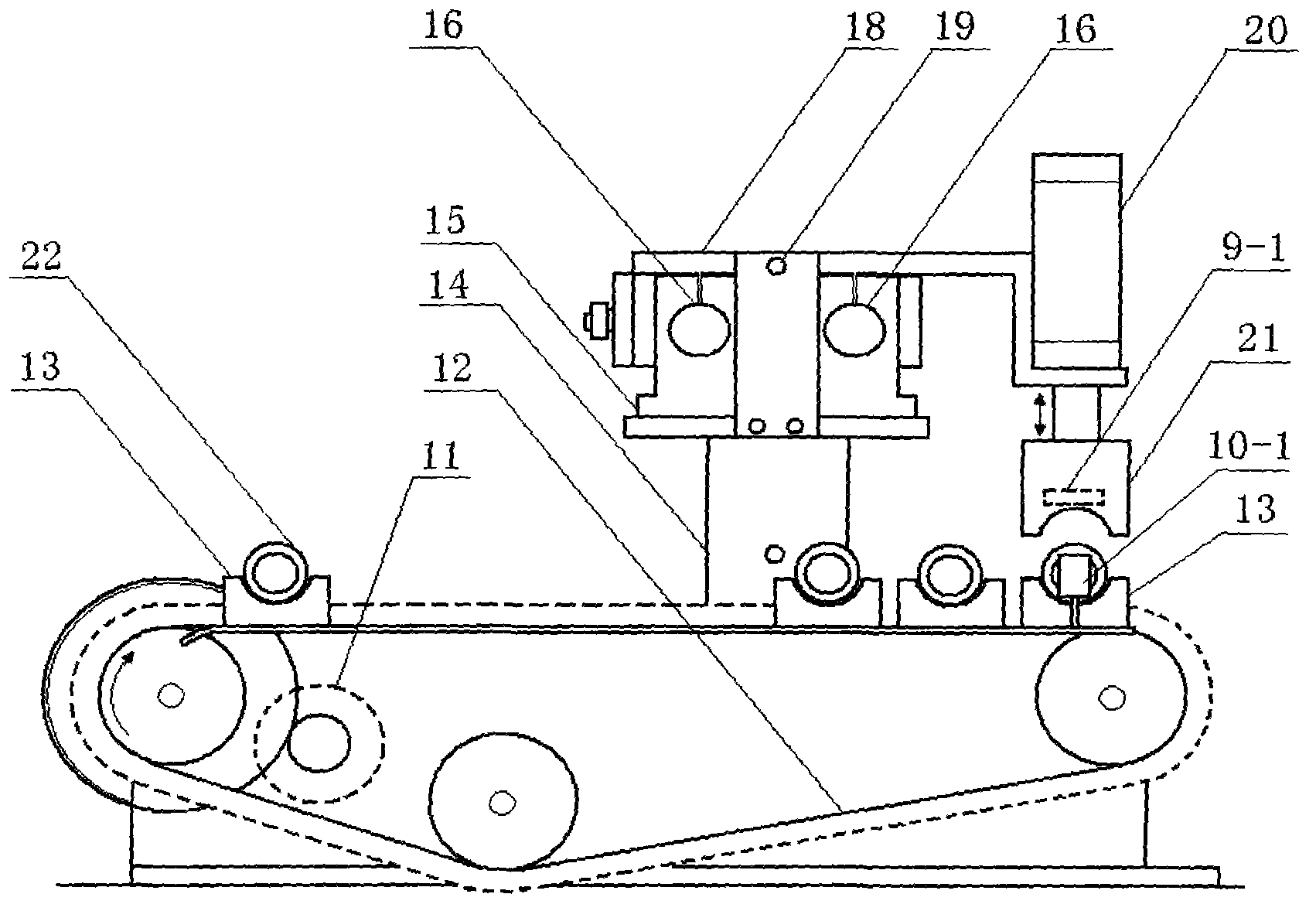

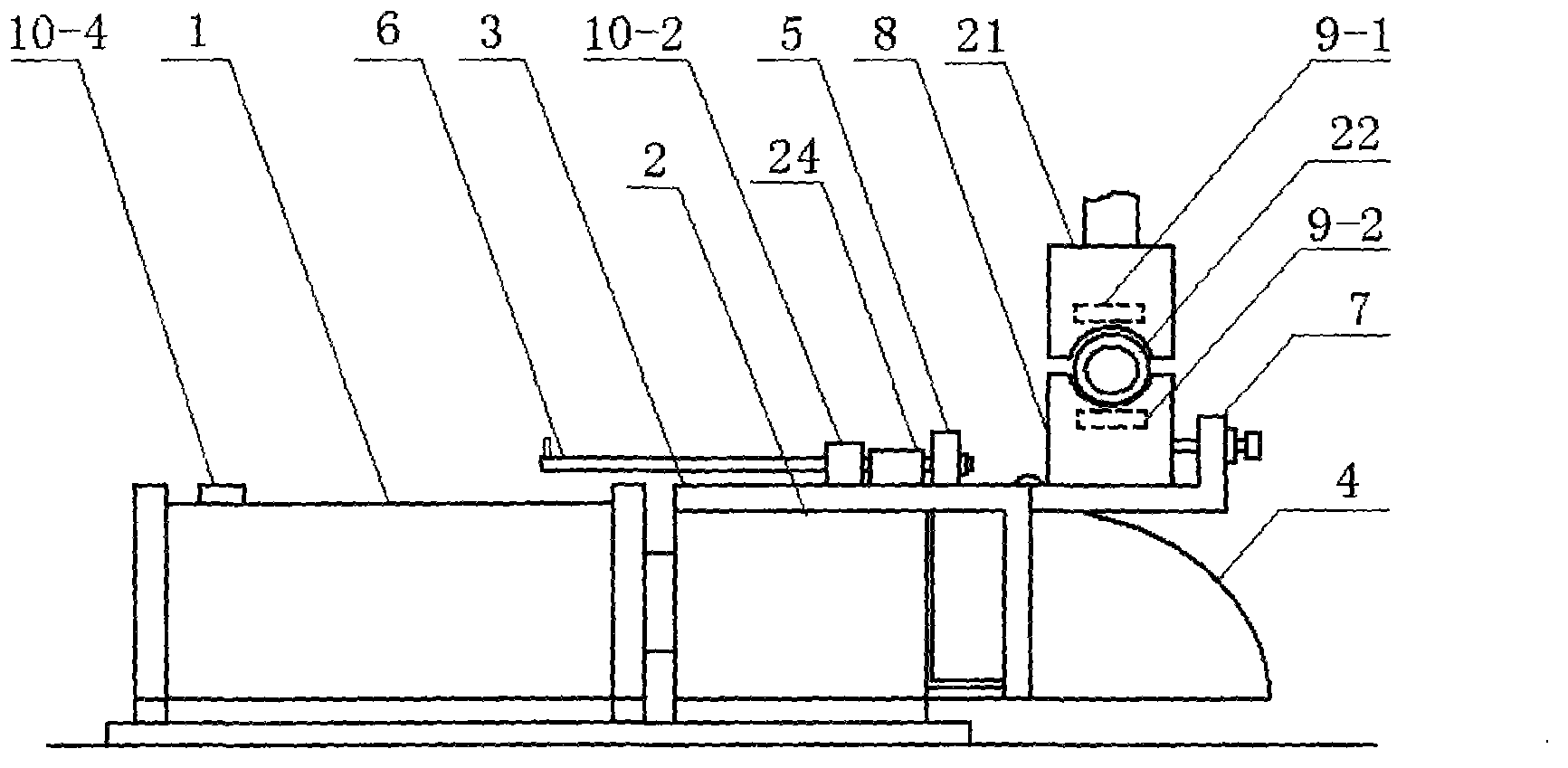

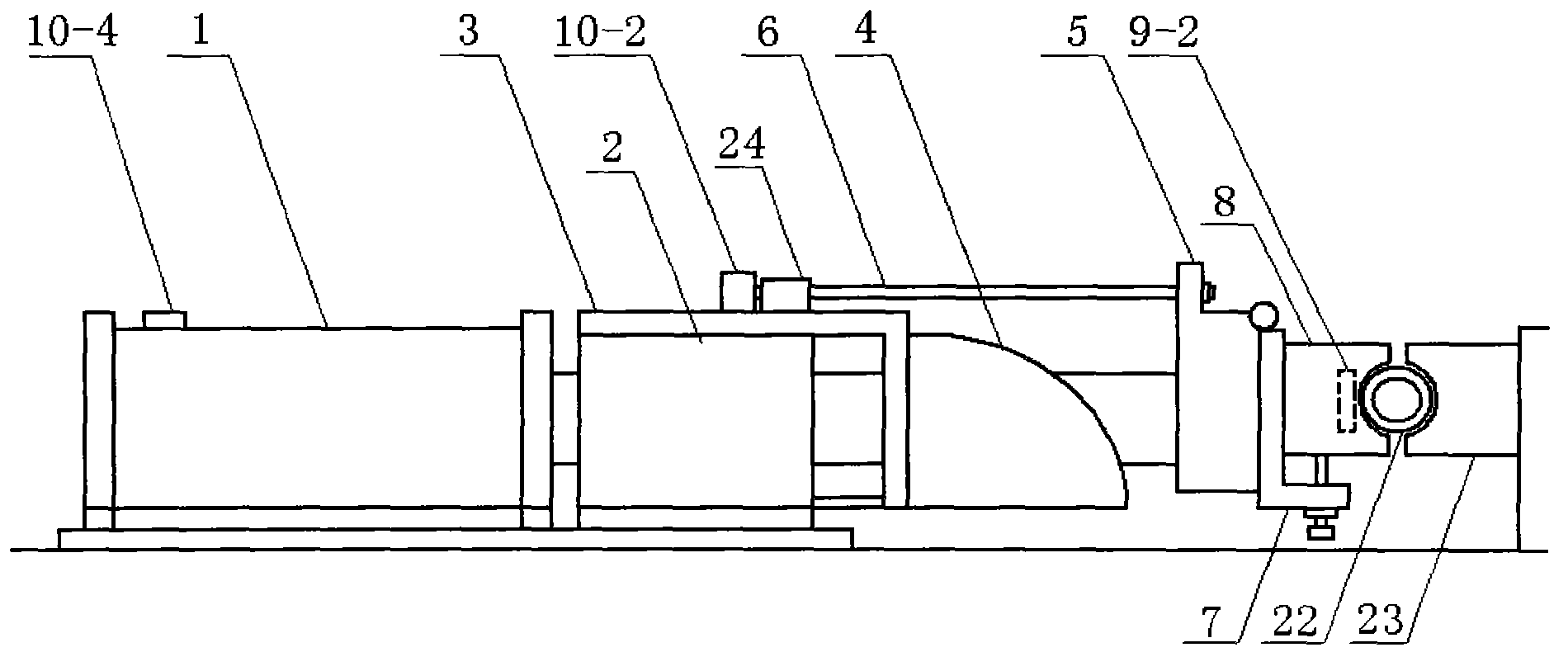

[0019] Such as Figure 1-4 As shown, the present invention includes a feeding cylinder 1, a guide seat 2, a support 3, an overturning slideway 4, a connecting plate 5, a guide rod 6, a fixture seat 7, a movable fixture 8, The feeding mechanism and detection switches 10-1, 10-2, 10-3, 10-4 formed by electromagnet 9-2 also include a low-speed motor 11, a chain 12, and a material holder arranged on one side of the manual clamping station. 13, and the supporting plate 14, guide column frame 15, guide column 16, material transfer cylinder 17, linear bearing body 18, limit screw 19, and material suction cylinder are arranged above the middle of the manual loading station. 20, the material-shifting mechanism that suction chuck 21, electromagnet 9-1 form.

[0020] Such as figure 1 , 2 , 4, before starting the machine, the linear bearing body 18 is at one end of the guide...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap