The loading and unloading device and application of the groove grinding machine for the outer ring of the automobile hub bearing unit

A technology for automobile wheels and bearings, applied in the direction of grinding machines, grinding feed movement, grinding/polishing equipment, etc., can solve the problems that the grinding speed cannot be significantly increased, the processing cycle of the workpiece is prolonged, and the loading and unloading time is reduced. The effect of non-processing time, less mechanical action, and fast loading and unloading speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

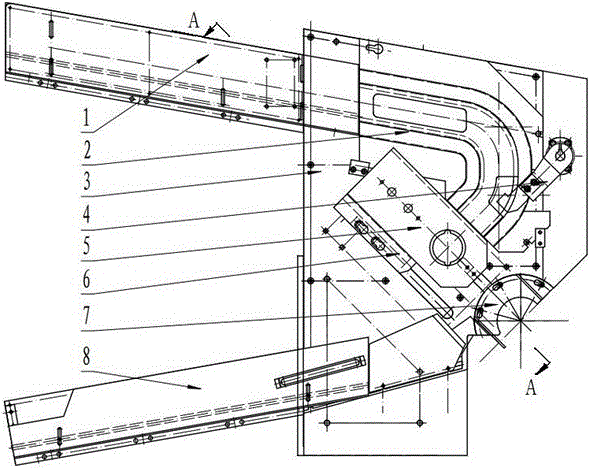

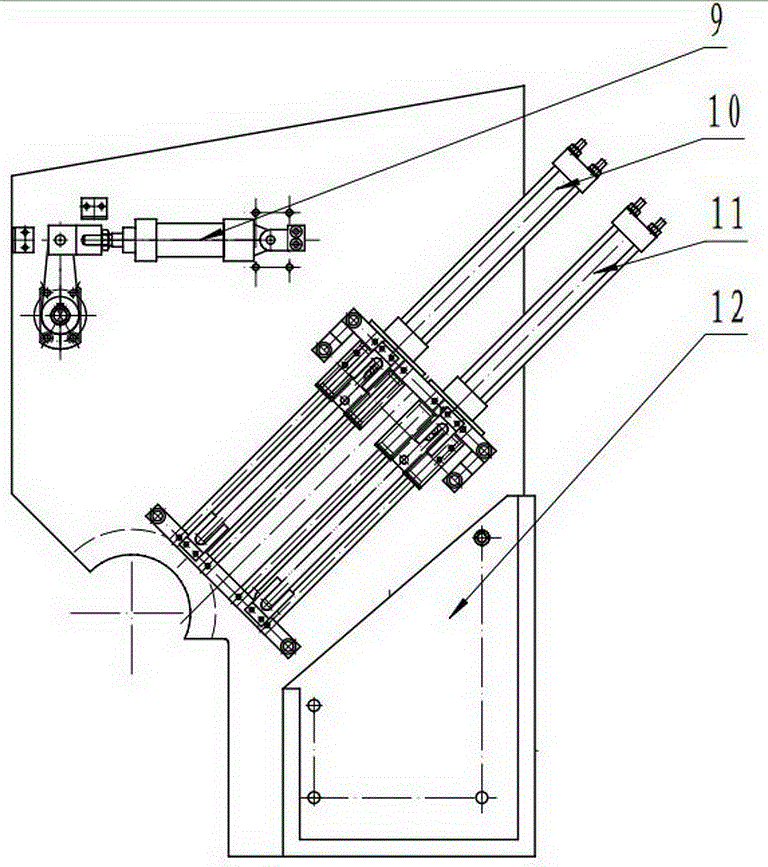

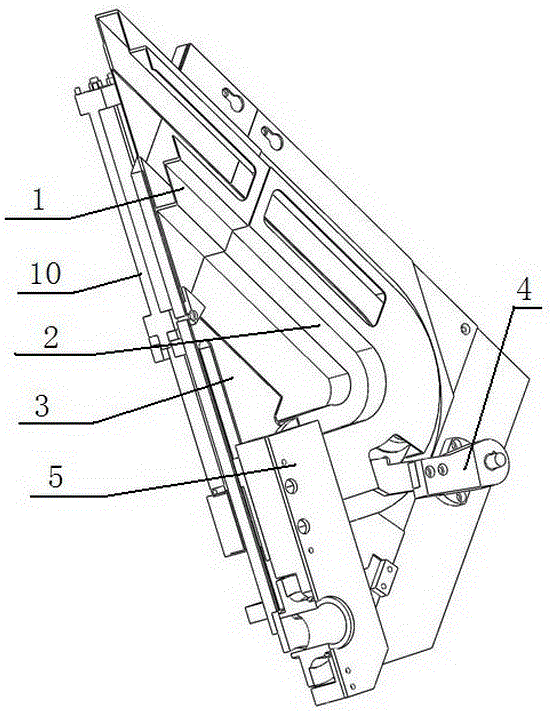

[0017] like figure 1 As shown, the loading and unloading device for the groove grinding of the outer ring of the automobile hub bearing unit includes a panel, and the panel is fixed on the panel support. The panel is fixedly equipped with an upper material passage, a transitional material passage, an unloading passage, a distribution oil cylinder, a main manipulator oil cylinder, an auxiliary manipulator oil cylinder, and an unloading passage. The cross-section of the feeding channel is in an inverted "T" shape. The transition channel is arc-shaped, and the cross-section is inverted "T" shape. The upper feed channel is connected with the transition feed channel. A material distributing manipulator is arranged on one side of the transition material channel, and the material distributing manipulator is connected with the material distributing oil cylinder. The main manipulator and the auxiliary manipulator are located at the end of the transition material channel. The main m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com