Multifunctional integrated engine assembly fixture

An assembly tooling and integrated technology, which is applied in the direction of hand-held tools, manufacturing tools, workpiece clamping devices, etc., can solve the problems of single function and inconvenient loading and removal of the engine, and achieve high functional integration and reduce bumps The risk of operation and the effect of saving effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

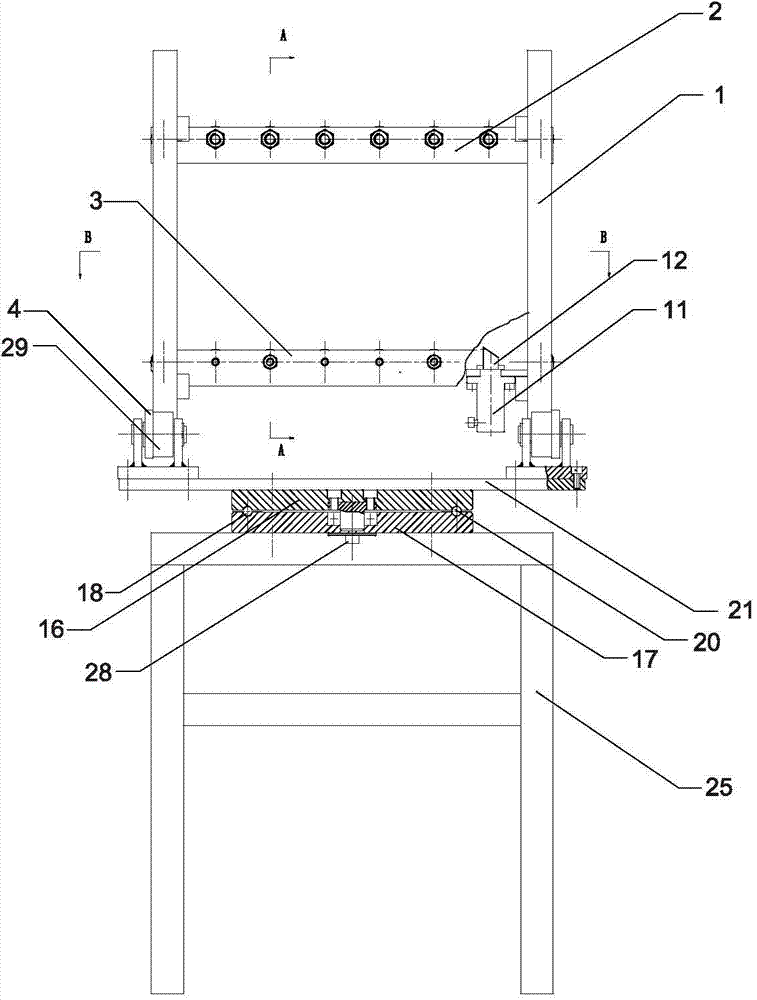

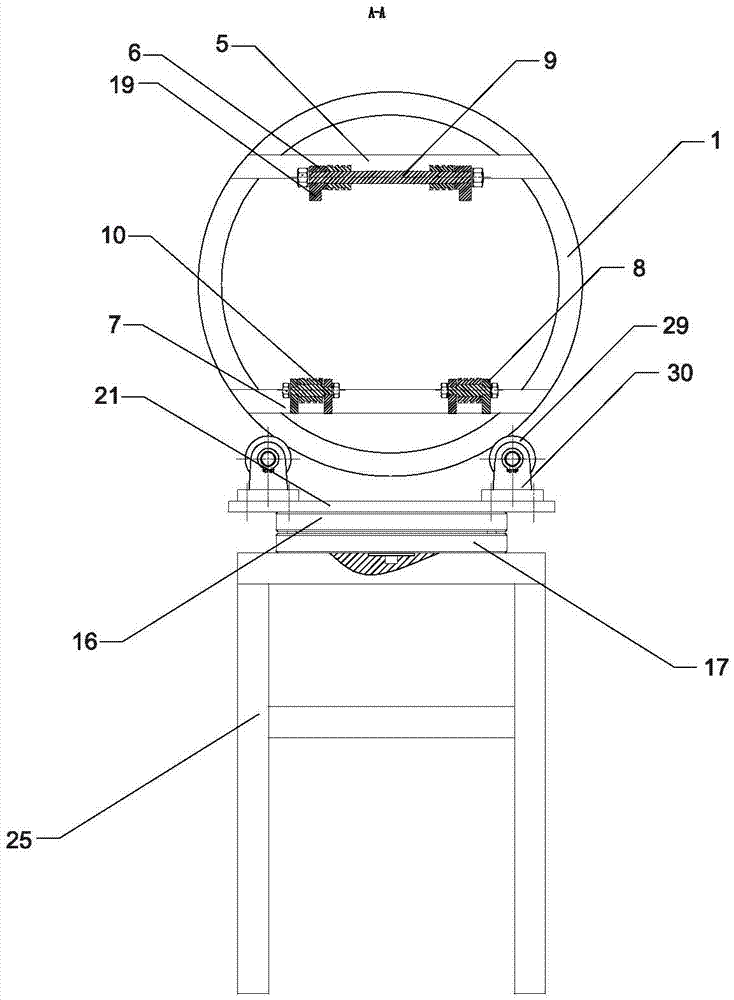

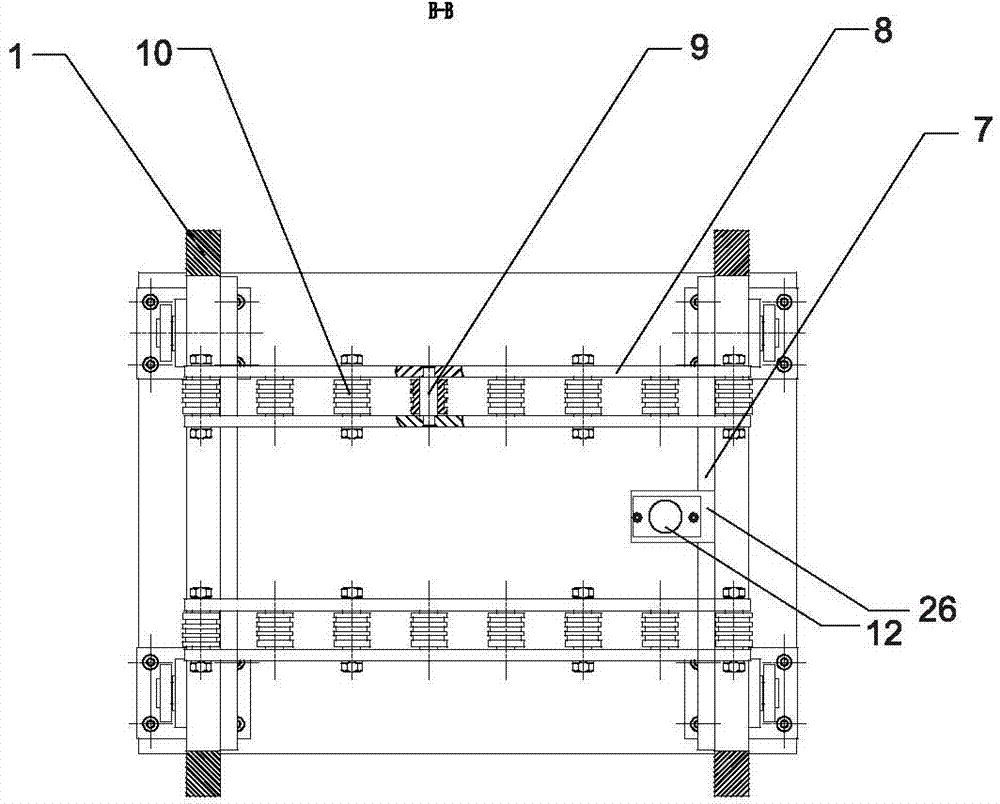

[0024] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a multifunctional integrated engine assembly tooling includes a base 21 and a tooling frame arranged on the base 21. The tooling frame includes two parallel and opposite circular rolling rings 1, an upper support frame 2 and a lower support frame 3 , the rolling rings 1 are equal in size and coaxial, the upper support frame 2 and the lower support frame 3 are fixed in the axial direction to integrate the two rolling rings 1, a turning mechanism is provided between the rolling ring 1 and the base 21, and the rolling ring 1 A transfer mechanism is provided between them, a horizontal rotation mechanism is provided under the base 21, and an axial limit mechanism is also provided on the tooling frame. Described overturning mechanism comprises the set of guide wheels corresponding to roller ring 1, and each set of guide wheels comprises a pair of guide wheels 29, and guide wheels 29 are fixed on the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com