Ratchet wrench

A ratchet wrench and wrench technology, applied in the ratchet wrench field, can solve the problems of large rotation space and no opening of the ratchet wrench, and achieve the effect of small assembly space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

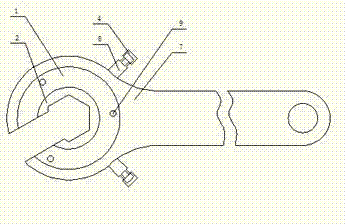

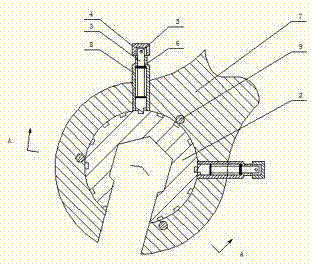

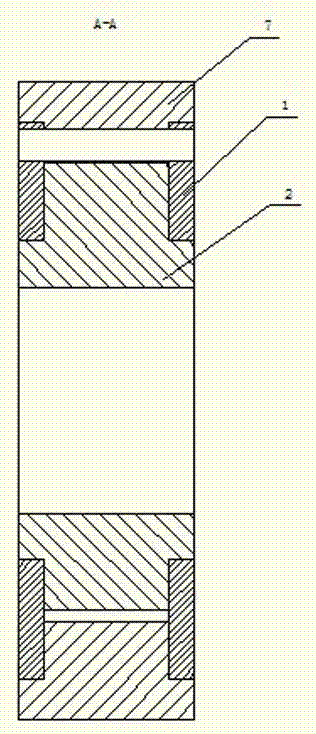

[0018] exist figure 1 , 2 and 3, a ratchet wrench includes a wrench head 2, a wrench body 7 with an extended handle, and a ratchet pawl mechanism. The head of the ratchet wrench is provided with a lateral rectangular opening. The outer cylindrical surface of the wrench head 2 is provided with a rectangular ratchet to cooperate with the inner cylindrical surface of the head of the wrench body 7 with an extended handle, and is fixed in the inner cylindrical surface of the head of the wrench body 7 through the axial limit of the cover plate 1. The wrench head 2 can rotate freely in the inner cylindrical surface of the head of the wrench body 7 . The cover plate 1 is a sheet-shaped ring structure, and is fixed on the wrench body 7 through the cover plate positioning pin 9 . The center of the wrench head 2 is provided with a regular hexagonal inner hole, which is used to cooperate with the hexagonal nut. The radius of the inner circle of the sheet-shaped annular structure cover p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com