Shaft workpiece electroplating epicyclic frame

A technology of shaft workpieces and turnover frames, which is applied in the field of shelves, can solve problems such as troublesome shaft parts are easy to bump, and difficult to count

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

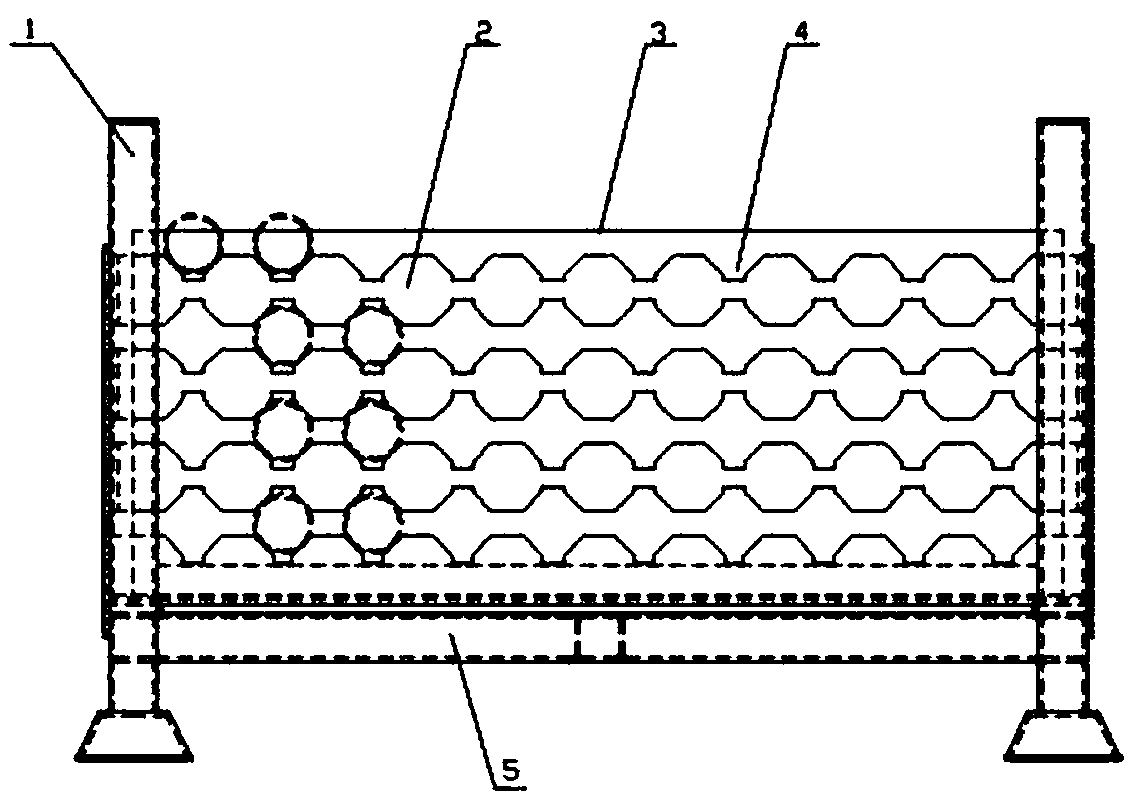

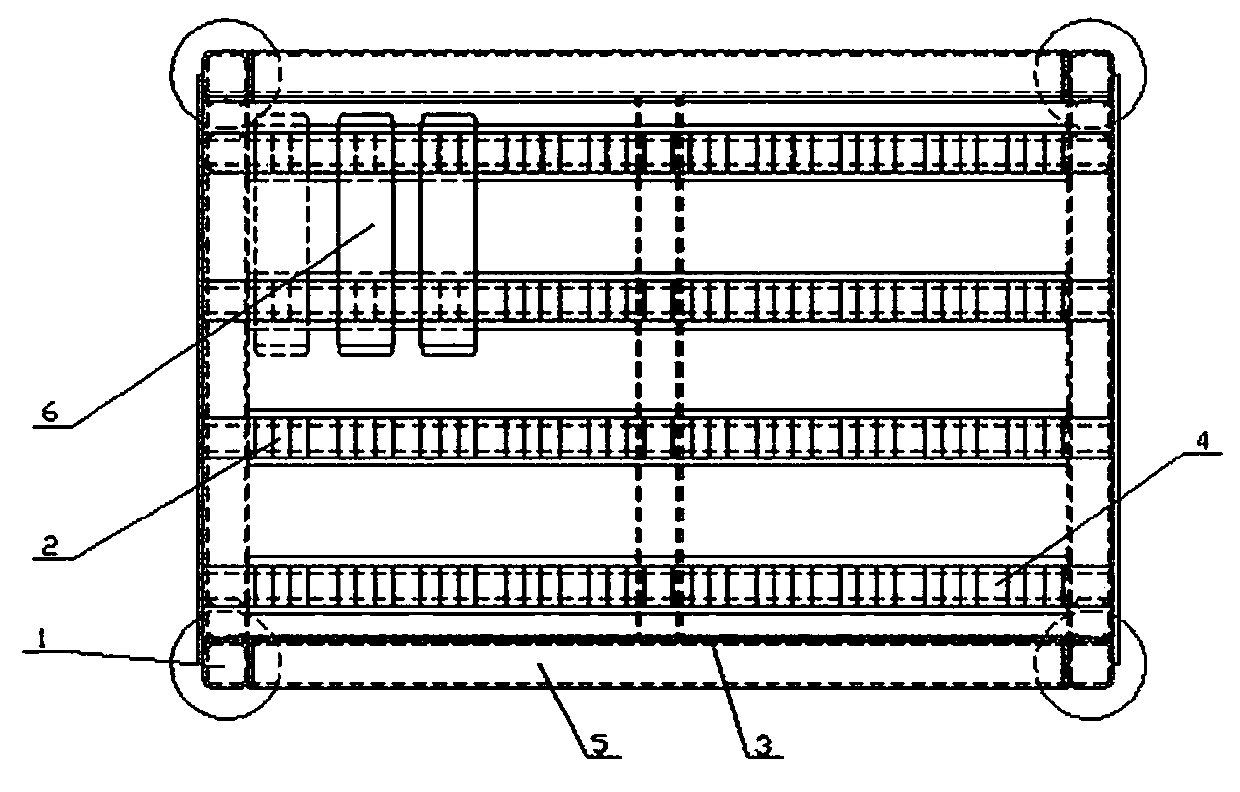

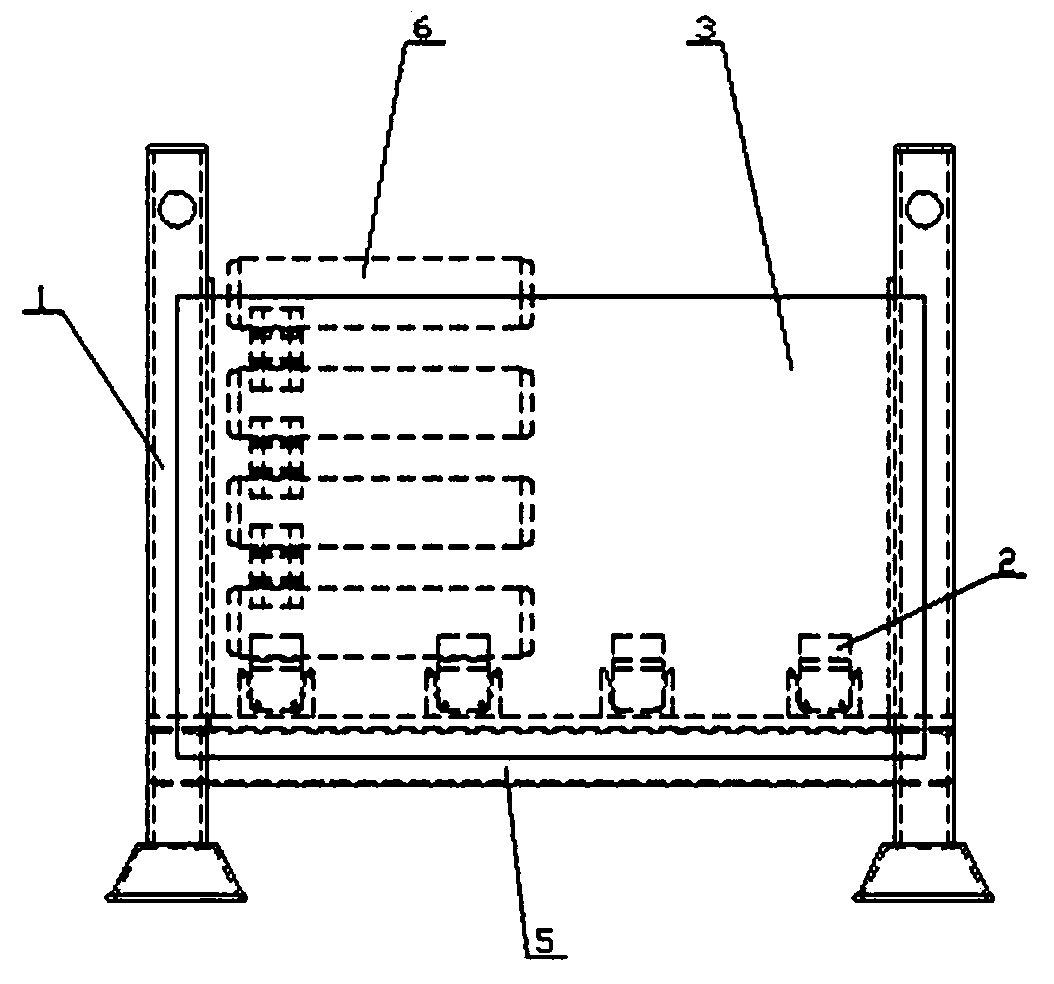

[0013] Such as figure 1 , figure 2 with image 3 As shown, the electroplating turnover rack for shaft workpieces of the present invention includes four columns 1, which are arranged symmetrically in a quadrangular shape, and there are connecting rods 5 between the lower ends of the two adjacent columns 1, and the two adjacent columns 1 room is connected with the hoarding board 3, thus constitutes a rectangular frame projected. Four layers of struts 2 are arranged between a pair of opposite shrouds 3 , and the two ends of each strut 2 are detachably connected to the corresponding shrouds 3 . The upper and lower sides of the strut 2 are evenly distributed with transverse grooves 4 longitudinally, and the 4 transverse grooves on the upper and lower sides of all the struts 2 correspond to each other, and the 4 transverse grooves on the opposite surfaces of the adjacent two struts 2 There is a space for placing shaft workpieces 6 .

[0014] Wherein, the number of struts 2 in e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com