Hybrid four-wheel drive chassis structure

A technology of hybrid electric vehicles and four-wheel drive, which is applied in the field of automobiles, can solve the problems that affect the large-scale promotion of hybrid electric vehicles, the battery pack is easy to catch fire or explode, and the transmission vibration and noise are large, so as to improve fuel economy and benefit Good maintenance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

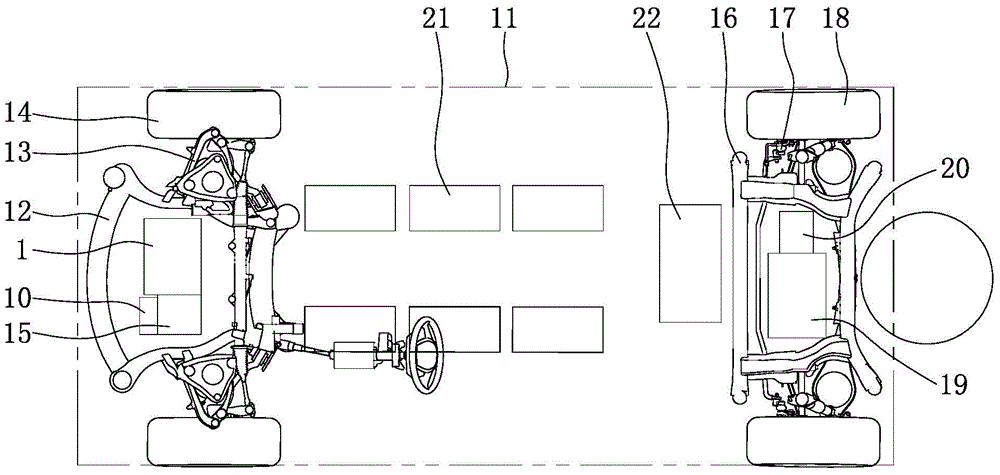

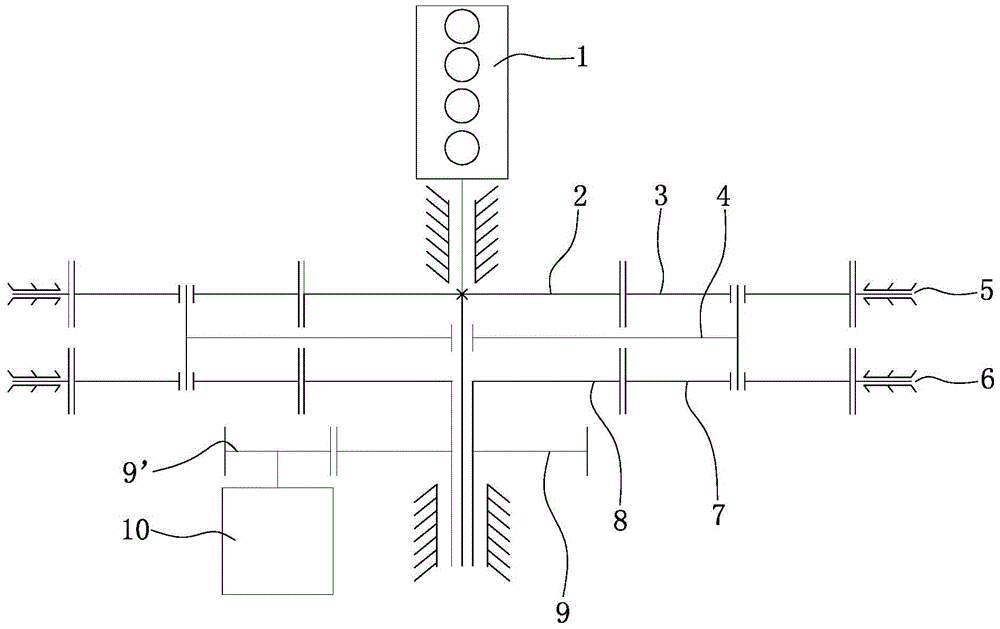

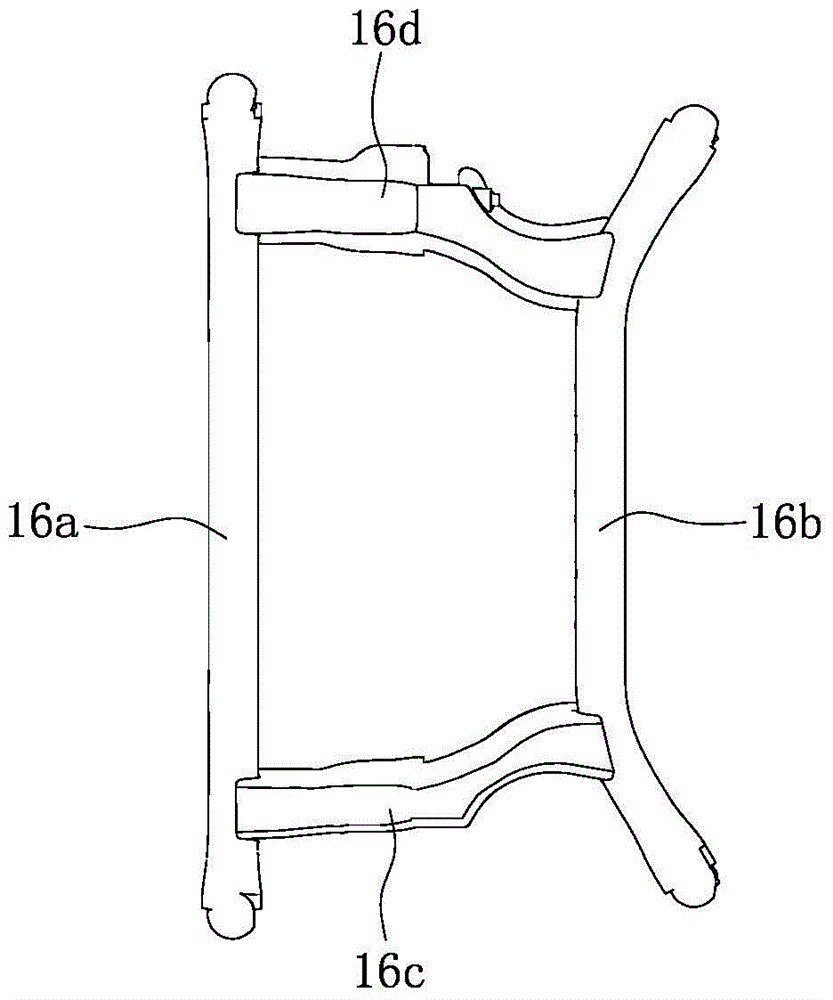

[0040] Such as figure 1 , figure 2 and image 3Shown, the present invention is by lower vehicle body 11, front auxiliary frame 12, front suspension 13, front wheel 14, front gearbox 15, rear auxiliary frame 16, rear suspension 17, rear wheel 18, driving motor 19, The rear gearbox 20, the battery pack 21, the fuel tank 22 and the like are composed. Wherein, the front subframe 12 is fixed at the front part below the lower vehicle body 11, and the front subframe 12 is a frame structure, and front wheels 14 are symmetrically arranged on the left and right sides of the front subframe 12, and each front wheel 14 passes through. The front suspension 13 is connected to the front subframe 12 . An engine 1, an ISG motor 10 and a front gearbox 15 are arranged in the front sub-frame 12, the ISG motor 10 is located next to the front gearbox 15, and the ISG motor 10 and the front gearbox 15 are located on the same side of the engine 1 . The first sun gear 2 is fixedly sleeved on the o...

Embodiment 2

[0055] see figure 1 , the present embodiment does not have the ISG motor 10 and the corresponding power coupling mechanism, the output shaft of the engine 1 is connected to the input end of the front gearbox 15, and the power of the engine 1 is directly transmitted to the front gearbox 15. The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com