End module, especially front-end module for transport

A technology for transportation tools and front-end modules, applied in the directions of transportation and packaging, vehicle components, superstructures, etc., can solve the problem of difficult implementation of interference contours, and achieve the effect of ensuring orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

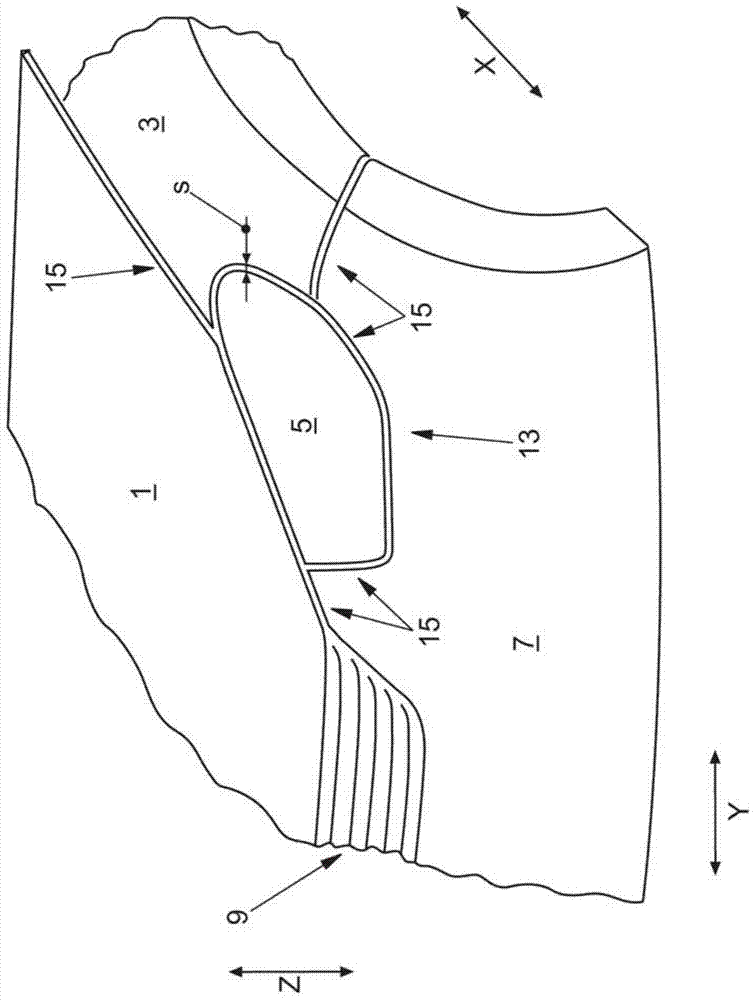

[0025] exist figure 1 The front end of the vehicle is shown in a partial perspective view in . The front lid 1 , the side panels 3 , the headlights 5 and the bumper trim 7 can thus be seen. A cooler grille 9 is integrated in the bumper trim 7 . figure 1 Also shown is a seam pattern 13 which is produced by the arrangement of the front cover 1 , side panels 3 , headlights 5 and bumper trim 7 . The seam configuration 13 is formed by a seam 15 with a gap dimension s. In order to form a visually flawless, uniform seam pattern 13, the gap size s of the seams 15 is the same.

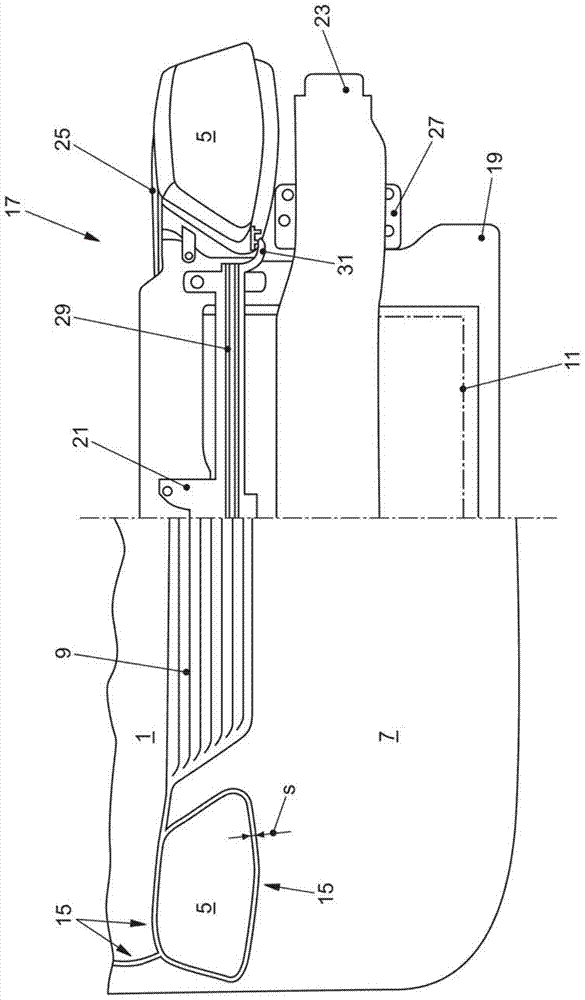

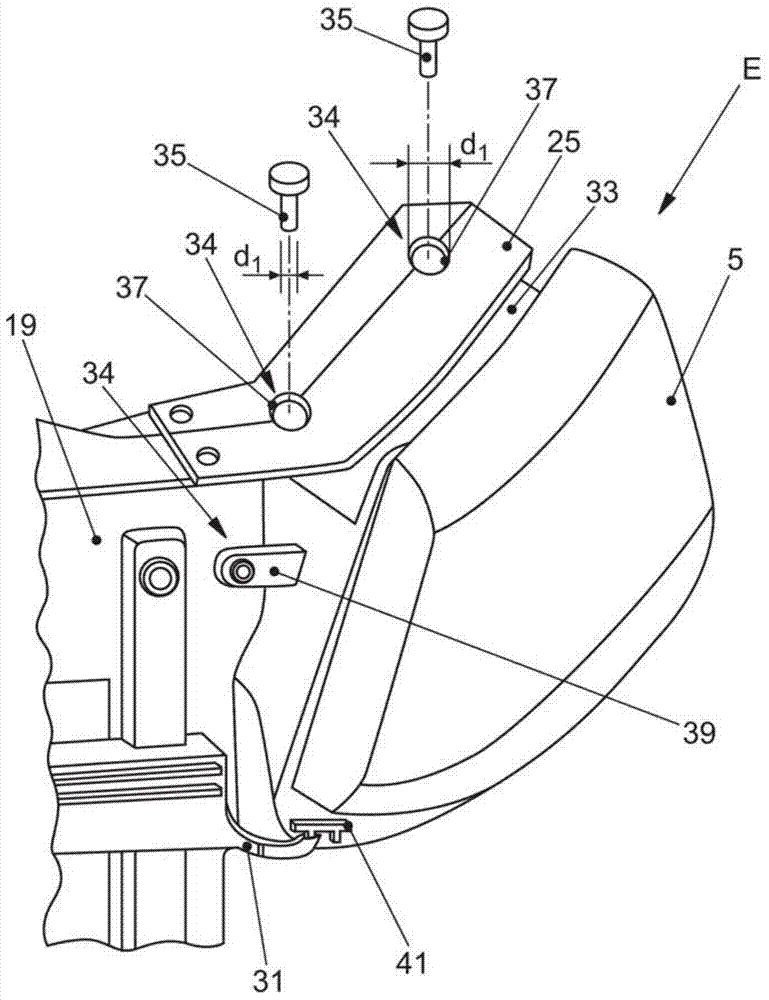

[0026] exist figure 2 A front view of the front end of the vehicle with the bumper fascia 7 and the cooler grille 9 partially removed is shown in FIG. therefore figure 2 Shown is a front-end module 17 consisting of headlight 5 , cooler 11 shown in dotted lines, plastic mounting bracket 19 for mounting parts, plastic guide strip 21 , bumper cross member 23 and headlight bracket 25 . The bumper beam 23 h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap